Polyester resin composition, process for producing the same, and polyester film

一种聚酯树脂、制造方法的技术,应用在聚酯薄膜领域,能够解决困难等问题,达到异物少、色调优良、防止油剂的污染的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] Add about 123 g of bis(hydroxyethyl) terephthalate in advance to a slurry of 100 kg of high-purity terephthalic acid (manufactured by Mitsui Chemicals) and 45 kg of ethylene glycol (manufactured by Nippon Shokubai Co., Ltd.). Add them sequentially to maintain a temperature of 250 ° C, a pressure of 1.2 × 10 5 In the esterification reaction tank of Pa, after the feeding was completed, the esterification reaction was further performed for 1 hour, and 123 kg of the esterification reaction product was transferred to the polymerization tank.

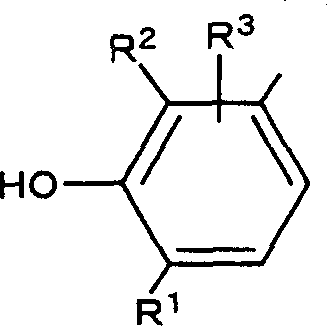

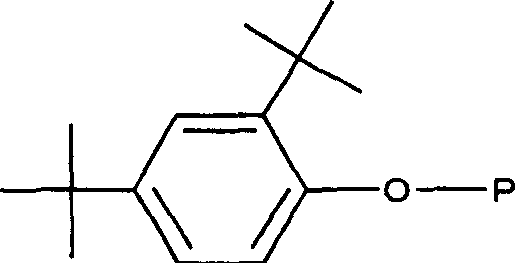

[0157]Next, in the above-mentioned polymerization reaction tank in which the esterification reaction product was transferred, 10 ppm of titanium sodium lactate chelate was added in terms of titanium atomic weight, and then 100 ppm of phosphorus-based antioxidant "PEP45" was added to the polymer. (registered trademark), add the magnesium acetate solution that is 70ppm by magnesium atomic weight, add the phosphoric acid that is 10ppm by ...

Embodiment 2

[0160] In Example 1, heat treatment was carried out in the same manner as in Example 1, except that the predetermined torque was lowered and the fragments obtained after the polymerization had an intrinsic viscosity of 0.45 dl / g were heat-treated to obtain an intrinsic viscosity of 0.58 dl / g. , the amount of the cyclic triploid is 0.25% by weight of the polymer (this polymer is denoted as polyester composition (B)).

Embodiment 3

[0162] In Example 1, heat treatment was carried out in the same manner as in Example 1, except that the predetermined torque was lowered and the fragments obtained after the polymerization had an intrinsic viscosity of 0.40 dl / g were heat-treated to obtain an intrinsic viscosity of 0.53 dl / g. . The amount of cyclic triploid is 0.20% by weight of polymer (this polymer is designated as polyester composition (C)).

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com