Desulfurization dust collector for industrial furnace

A technology for desulfurization and dust removal, industrial furnaces and kilns, which is applied in the field of atmospheric environmental protection equipment, can solve the problems of large investment in dust collectors, high power consumption, and the inability of small and medium foundry enterprises to bear the cost of dust removal, and achieves the effects of high dust removal efficiency and long contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

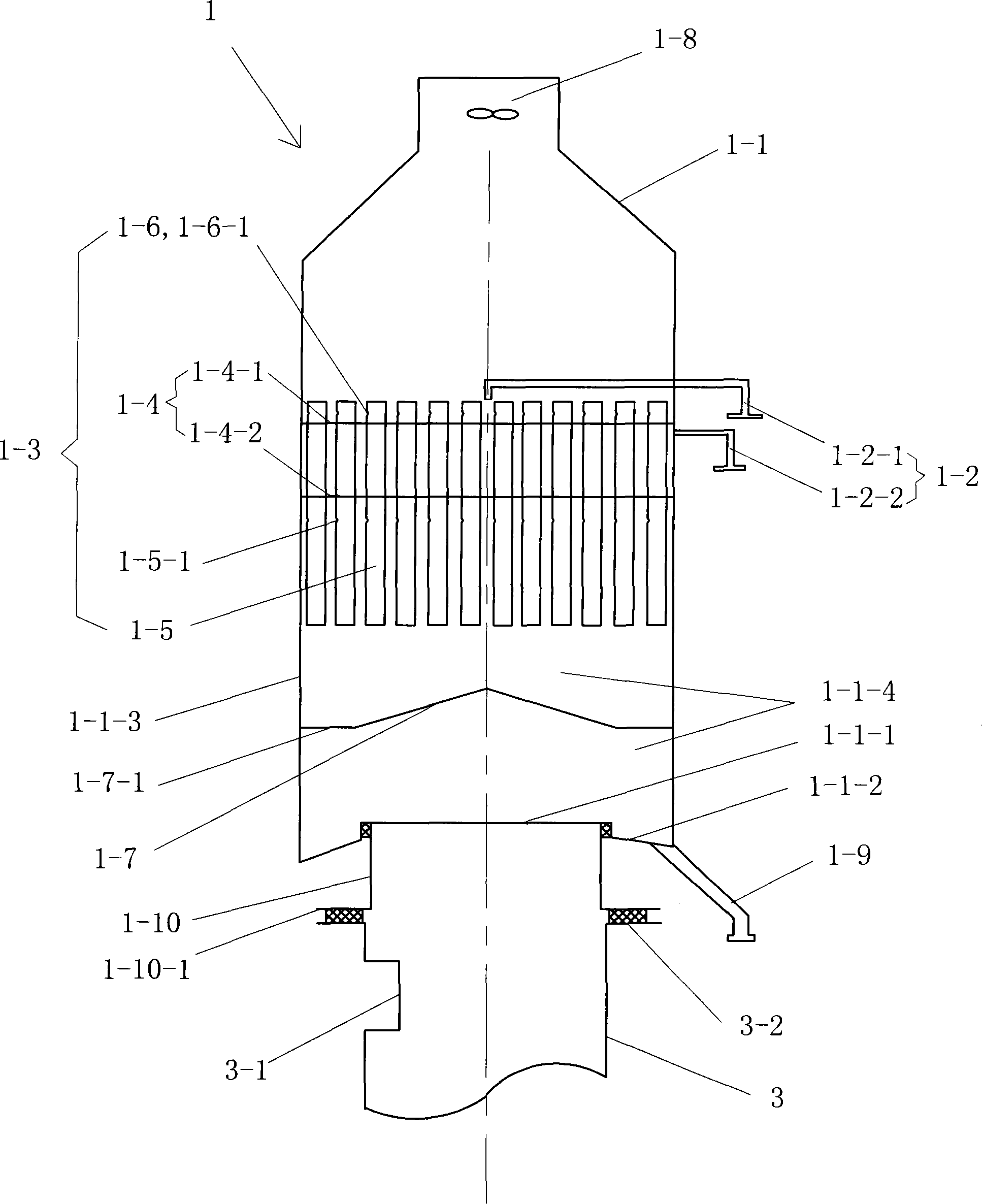

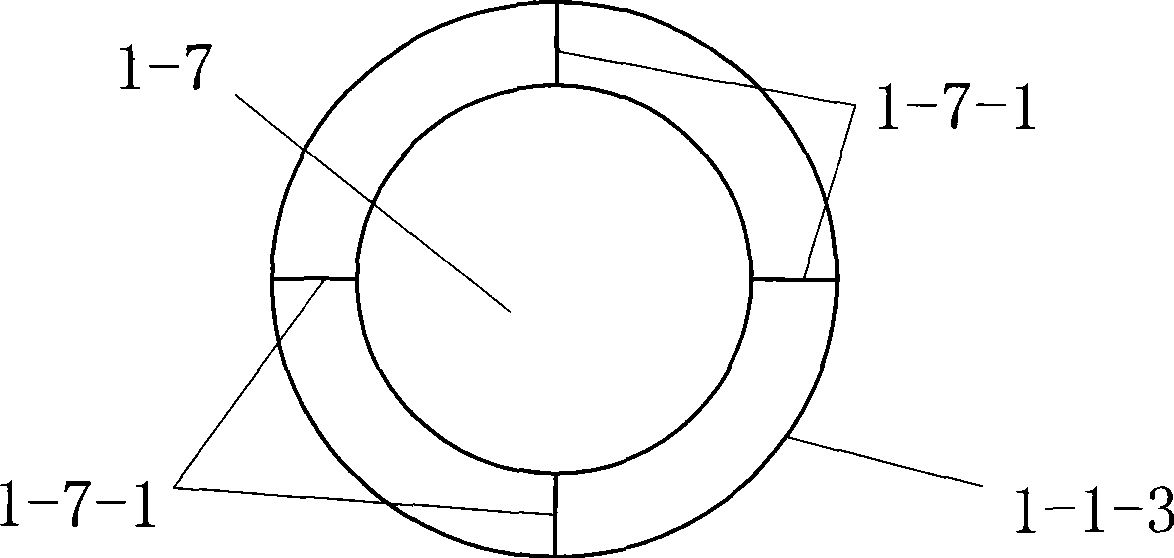

[0064] See figure 1 The desulfurization and dust removal device for industrial furnaces in this embodiment is a single-stage desulfurization and dust removal device. The desulfurization dust collector 1 includes a housing 1-1, and also includes a contact cooling spray device 1-3, a sewage pipe 1-9, a blocking cap 1-7, and a water inlet pipe 1- all fixed on the housing 1-1. 2. The water inlet pipe 1-2 is a component that provides water inlet to the contact cooling spray device 1-3 when in use. There is one sewage pipe 1-9, and the sewage pipe 1-9 is outside the housing 1-1, and its inlet is located at the lowest part of the housing 1-1 and communicates with the inner cavity of the housing 1-1.

[0065] Still see figure 1 The housing 1-1 has a flue gas inlet 1-1-1, an annular bottom plate 1-1-2 and an annular side plate 1-1-3. The flue gas inlet 1-1-1 is located at the bottom of the annular bottom plate 1-1-2 In the center, the annular bottom plate 1-1-2 and the annular side plate ...

Embodiment 2

[0078] see figure 1 , The rest is basically the same as embodiment 1, the difference is: in order to make the flue gas flow in the housing 1-1 smooth and not blocked, the upper end of the housing 1-1 is connected by a bracket (not shown in the figure) 1 exhaust fan 1-8.

Embodiment 3

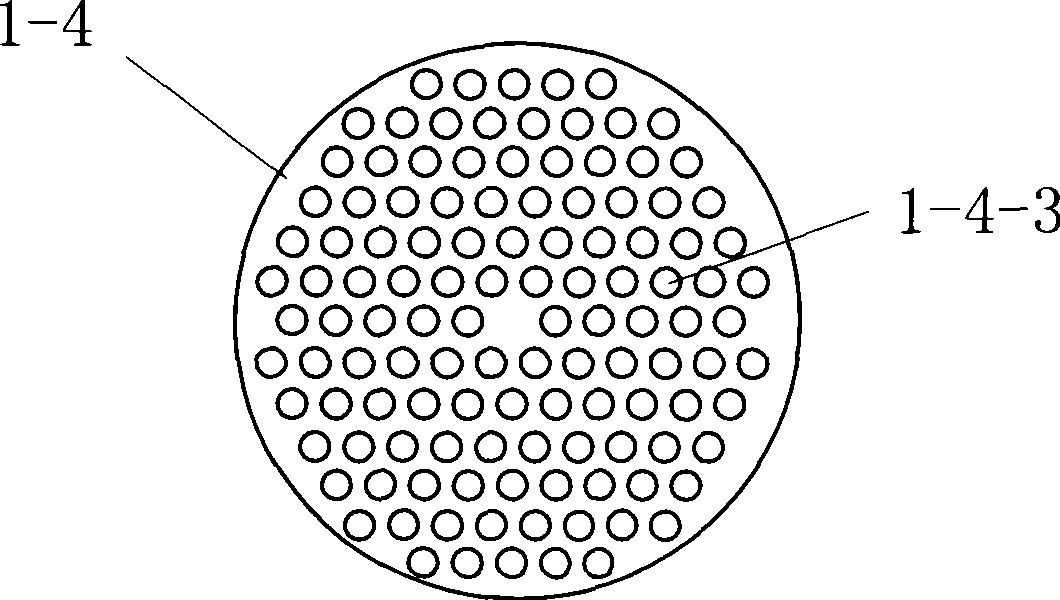

[0080] see Figure 5 This embodiment is basically the same as embodiment 2, except that: the contact cooling spray device 1-3 is also equipped with a liquid level balance pipe 1-3-1, and there are 6 liquid level balance pipes 1-3-1 , The liquid level balance pipe 1-3-1 passes through the corresponding pipe holes 1-4-3 of the upper tube plate 1-4-1 of the tube plate 1-4, and also passes through the corresponding pipe holes 1-4-2 of the lower tube plate 1-4-2 Tube hole 1-4-3. The fixing method is the same as that of the column tubes 1-5 fixed on the tube plate 1-4. The upper port of the liquid level balance pipe 1-3-1 is located from the height of the upper port of each single pipe of the column pipe 1-5 and the water inlet 1-6 of the water inlet 1-6 on each single pipe of the column pipe 1-5 Between -1. After installing the liquid level balance pipe 1-3-1, when the liquid level of the cooling water is higher than the water inlet part 1-6, it can flow into the pipe from the upper po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com