Desulfurization dust removing method of industrial furnace

A technology for desulfurization and dust removal, industrial furnaces and kilns, which is applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of high power consumption, large investment in dust collectors, and large investment, and achieve long contact time and high dust removal efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

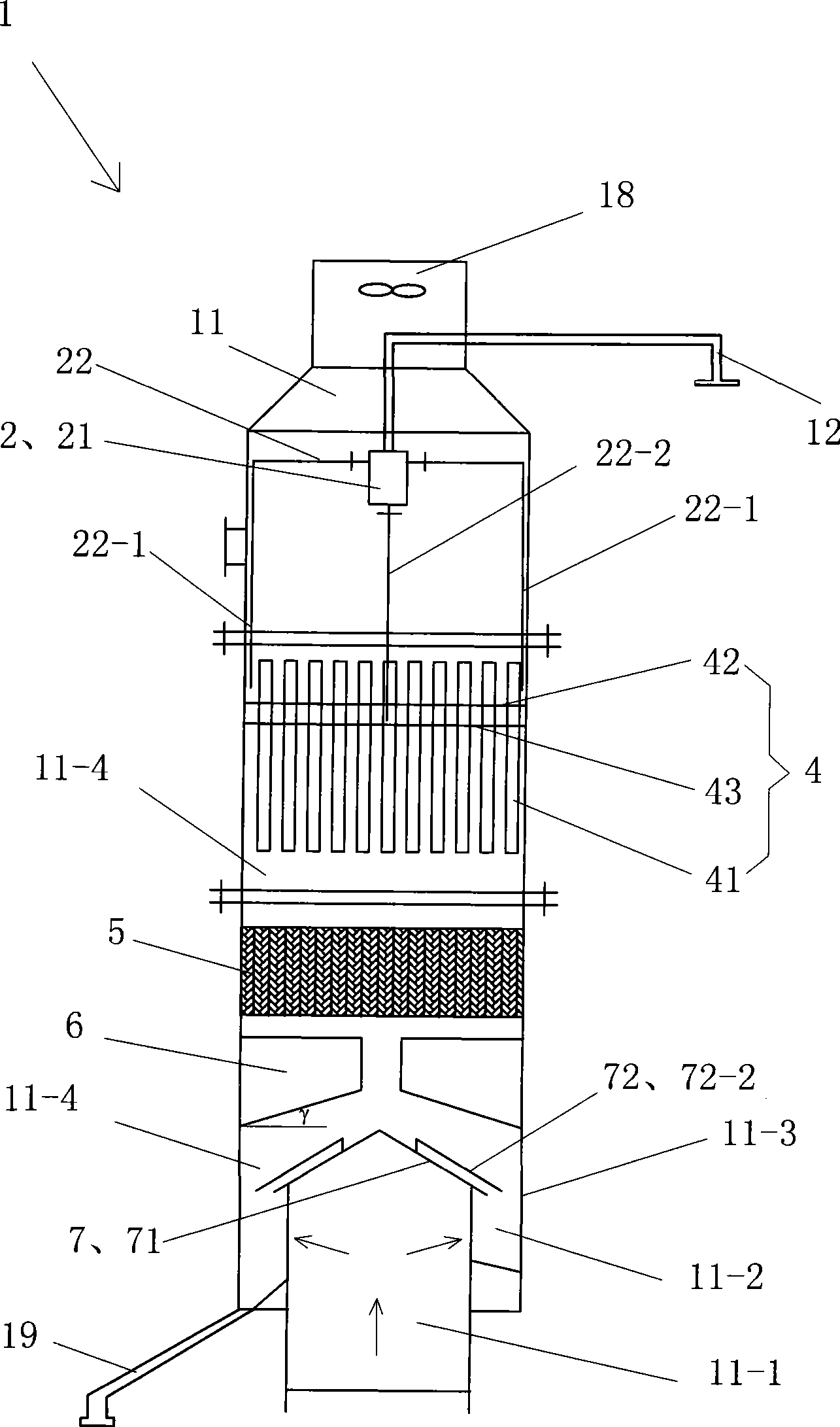

[0044] See figure 1 , the industrial kiln desulfurization and dedusting method of the present embodiment has the following steps:

[0045] ① Connect the flue gas inlet of the industrial furnace desulfurization and dust removal device 1 with the flue gas outlet of the industrial furnace. Sewage pipe 19, exhaust fan 18, water flow distributor 2, contact cooling spray device 4 and blocking cap 7.

[0046] The exhaust fan 18 is located in the housing 11 and at the upper opening of the housing 11, so that when the internal resistance needs to be reduced, the exhaust fan 18 can be activated to make the flue gas flow smoothly and not be blocked.

[0047] The housing 11 has a diameter of 2.6 m. The housing 11 has a flue gas inlet 11-1, an annular bottom plate 11-2 and an annular side plate 11-3, the flue gas inlet 11-1 is located in the center of the annular bottom plate 11-2, the annular bottom plate 11-2 and the annular side plate 11- 3 are airtightly connected together and locat...

Embodiment 2

[0057] still see figure 1 as well as Figure 4 , the method of the present embodiment is the same as embodiment 1, the difference is:

[0058] The desulfurization dust collector 1 in step ① also includes 18 swirl guide plates 6 arranged in the spray area 11 - 4 and above the blocking cap 7 . The shape of each swirl deflector plate 6 is the same, being a quadrangular plate, its upper edge is horizontal, its inner edge and outer edge all form a 90° angle with the upper edge, and the length of the outer edge is greater than the length of the inner edge , so that the lower edge is inclined with a high inside and a low outside, and the inclination angle γ is 25°. The plate body of each swirl flow guide plate 6 is welded and fixed on the annular side plate 11-3 of the housing 11 by its outer edge, and they are located at the same height position. On the same height, the plate body of each swirl guide plate 6 is at an angle of 10° to the diameter direction of the housing 11 passin...

Embodiment 3

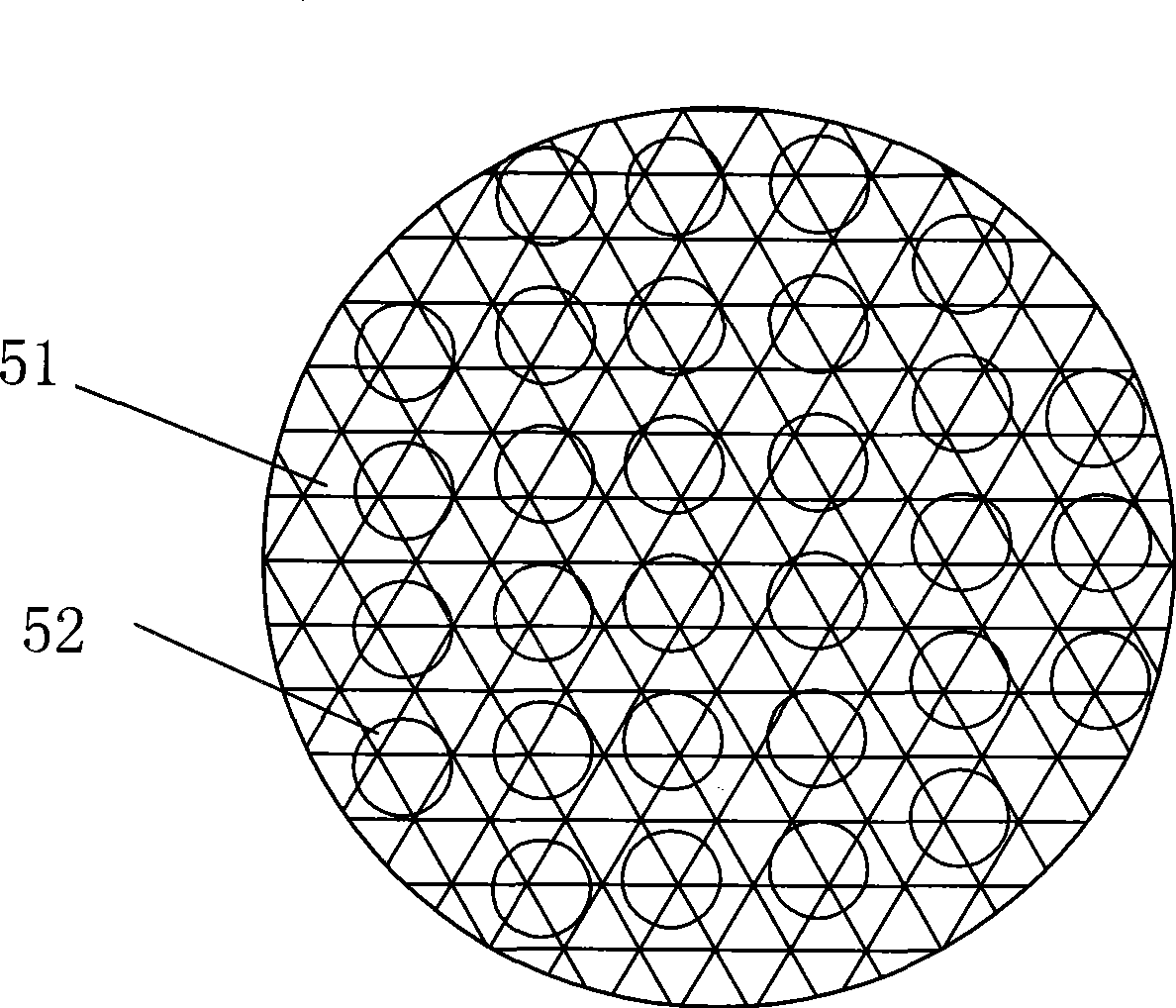

[0062] still see figure 1 as well as image 3 , the rest of the method of the present embodiment are the same as in embodiment 1, the difference is:

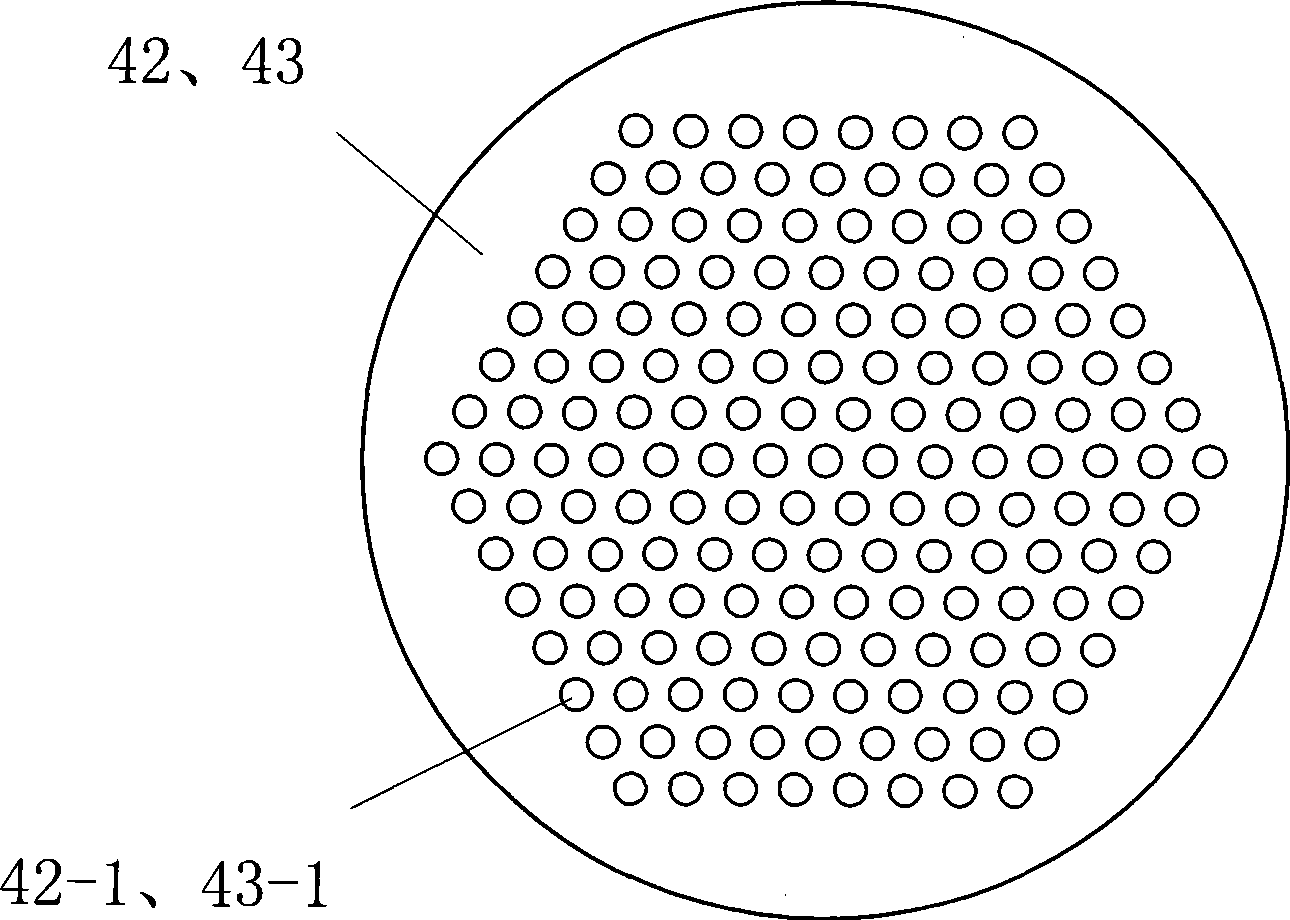

[0063]The desulfurization and dust removal device 1 in step ① also includes a scale mesh atomization device 5 . The scale mesh atomization device 5 is arranged in the spray area 11 - 4 and is located between the contact cooling spray device 4 and the swirl guide plate 6 . The scale-mesh atomization device 5 includes a mesh bottom plate 51 and each atomizing cylinder 52 is vertically parallel and closely arranged on the mesh bottom plate 51 . Each atomizing tube is made of steel rhombus perforated plate wound into a cylindrical shape.

[0064] In step ②, the cooling water that falls into the spray area from the contact cooling spray device 4 in a spray shape first falls on the scale mesh atomization device 5, and then falls from the scale mesh atomization device 5, wherein the cooling water Most of it falls on the swirl guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com