Combined purifying method and device

A technology of purification devices and purifiers, which is applied in the direction of combined devices, chemical instruments and methods, and separation methods, etc. It can solve the problems of inability to improve purification efficiency and dust removal efficiency, high cost of equipment operation and maintenance, and uneven dust in bag dust collectors, etc. problems, to achieve the effect of reducing maintenance workload, reducing system and equipment investment, and increasing the ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

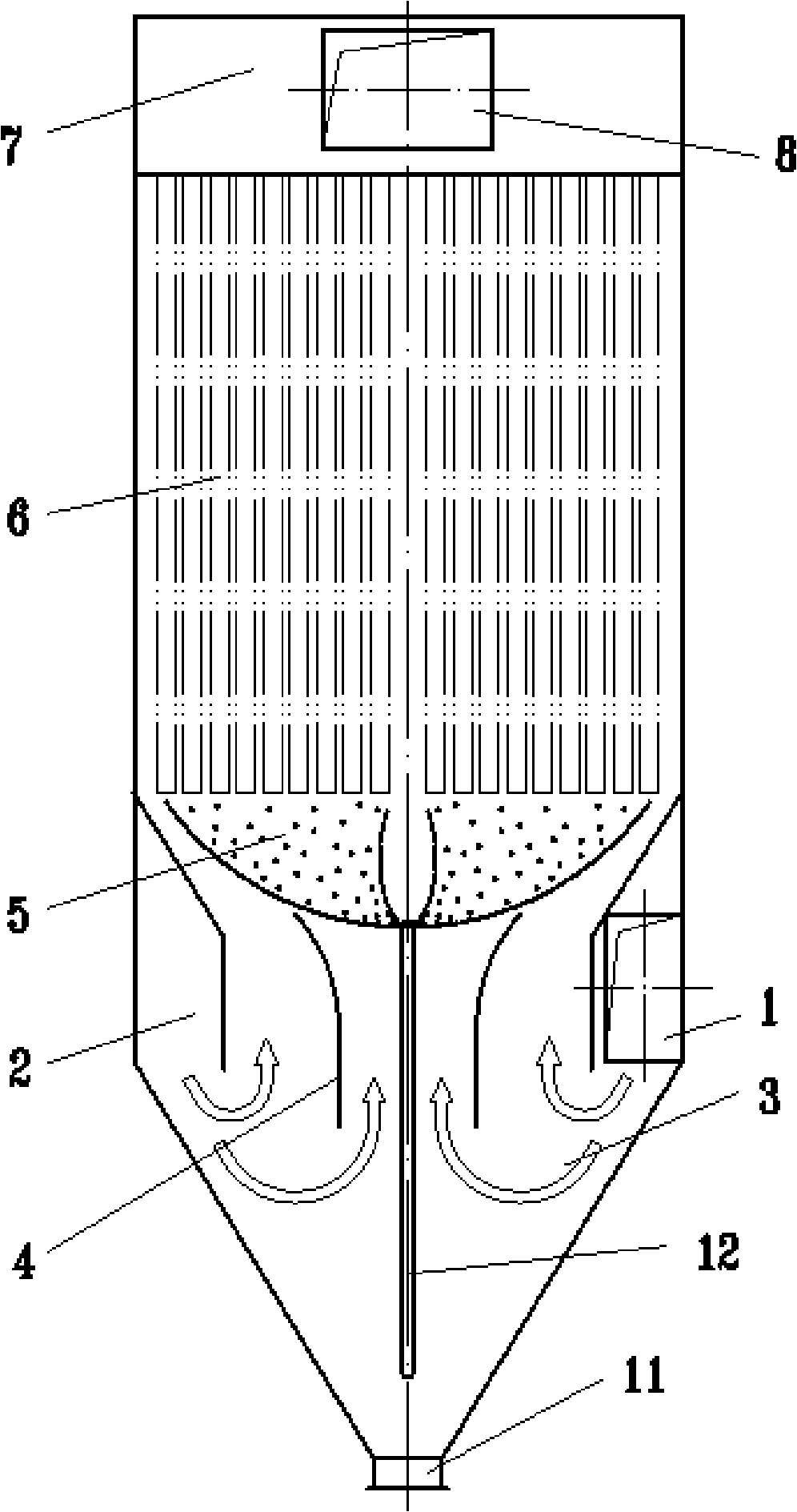

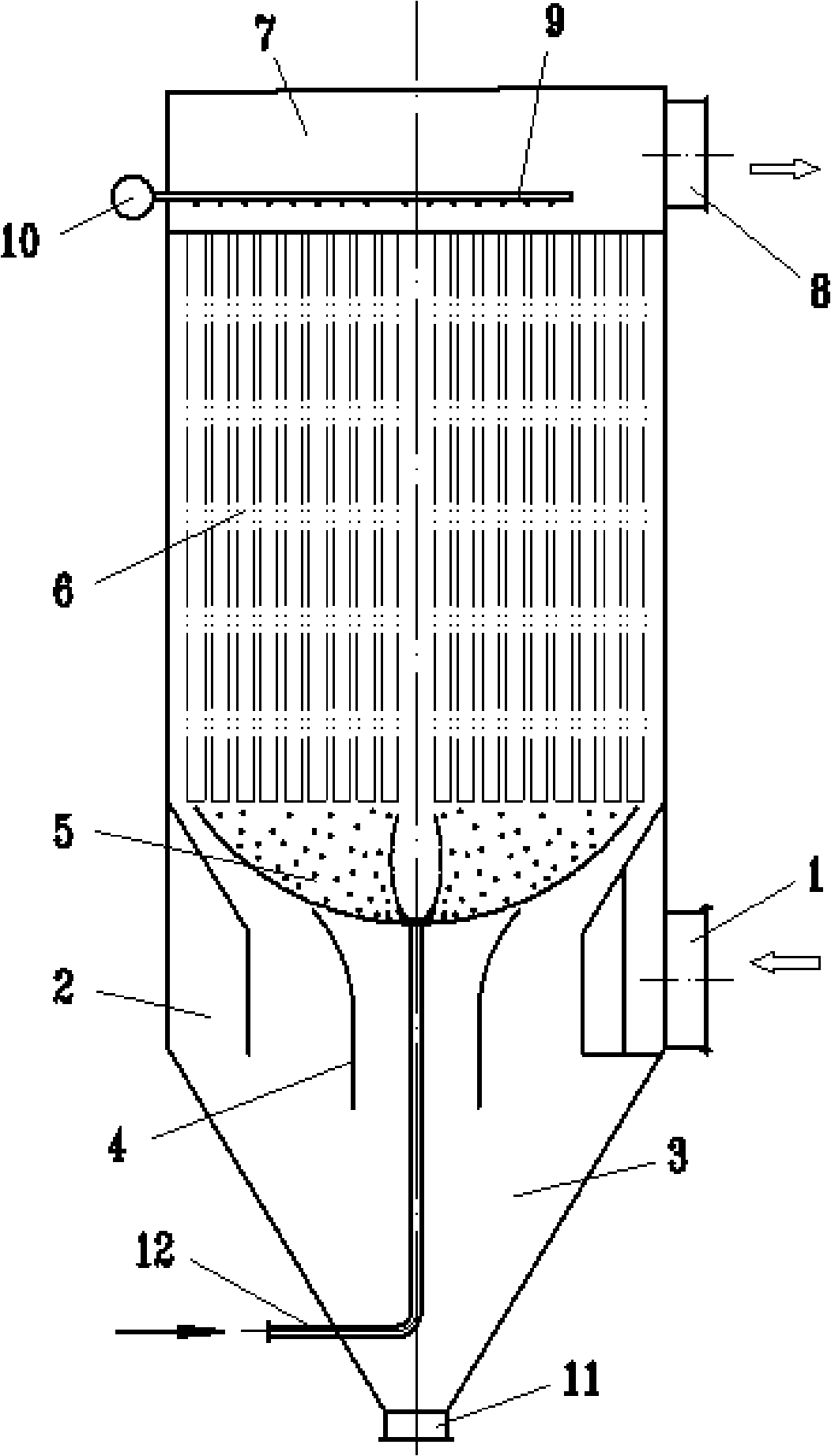

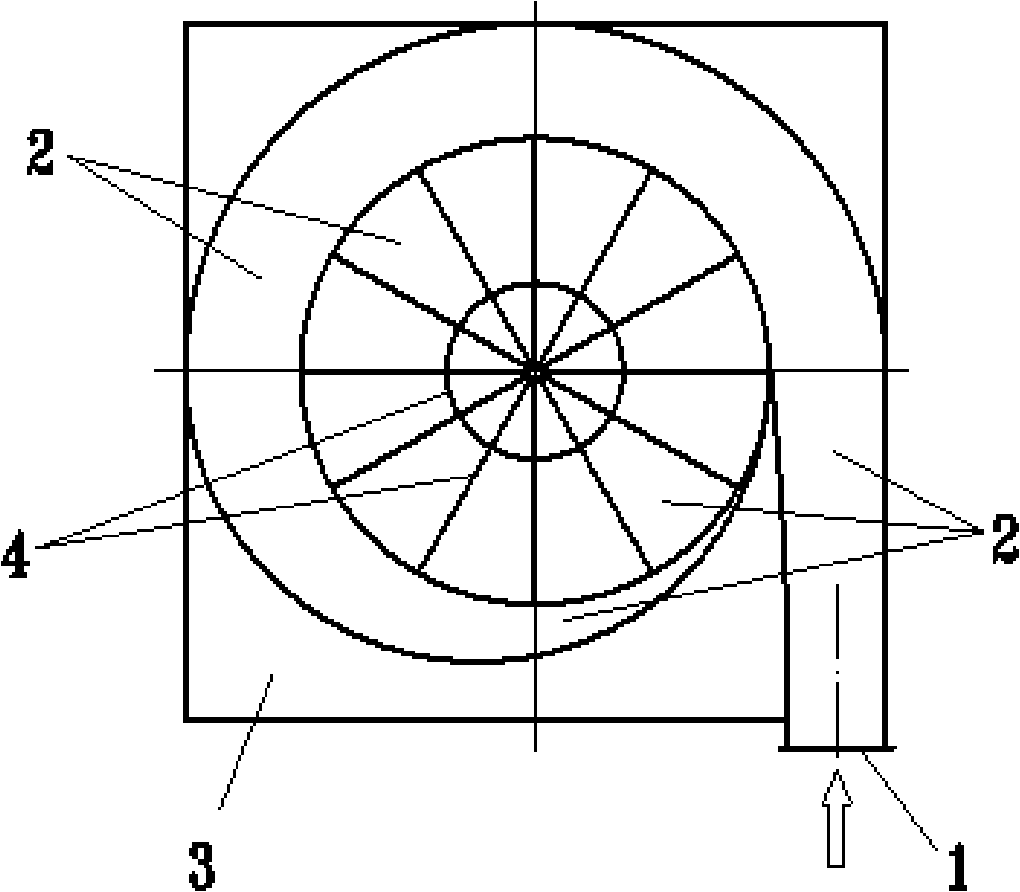

[0018] Embodiments of the present invention: the combined purification method of the present invention is as figure 1 , figure 2 with image 3 shown. This method combines cyclone dust removal and filter bag dust removal as a whole, and adopts two-stage dust removal; the first stage is cyclone dust removal, and the dust-laden gas enters the rotating flue 2 along the wall of the purifier, and the lower part of the rotating flue 2 opens, and the dust The gas rotates at a high speed in the annular rotating flue 2, and under the action of centrifugal force, the solid particles in the dust-containing gas are separated from the dust-containing gas in advance, and the ash hopper 3 along the lower part of the purifier settles at the bottom of the ash hopper 3; The second stage is filter bag dedusting. After the first stage cyclone dedusting, the dusty gas enters the filter bag chamber 5 from bottom to top through the ring hole of the circular rotating flue 2, and the ring hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com