Dust collecting and air cooling heat exchanger

A technology of air-cooled heat exchangers and cyclone dust collectors, which is applied to the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., which can solve the problems of low heat exchange efficiency and high use cost, and achieve high heat exchange efficiency , Small footprint and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

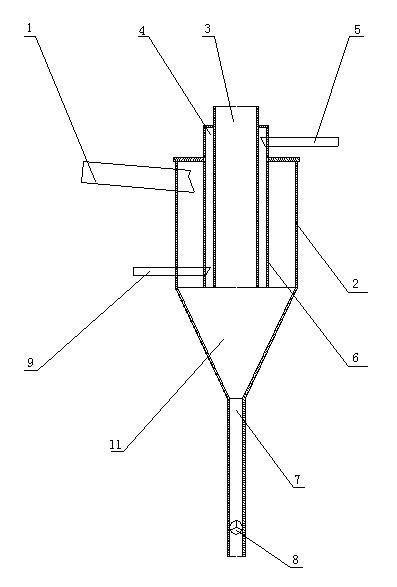

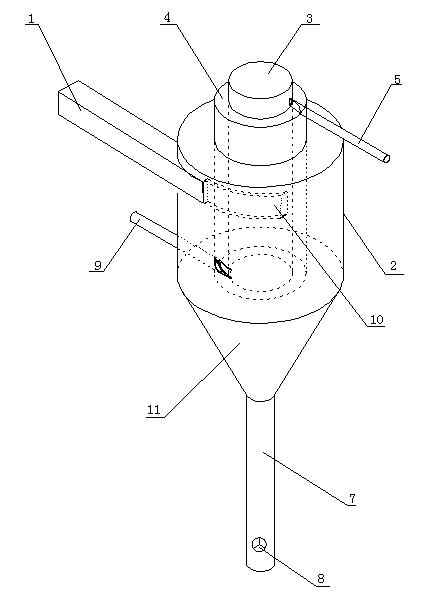

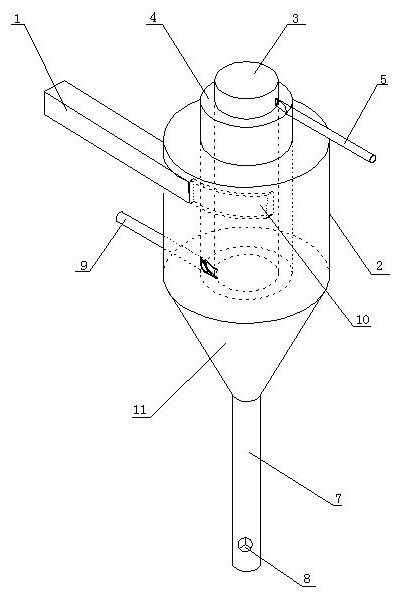

[0017] Example 1: A dust-removing air-cooled heat exchanger, the main body is a cyclone dust collector, a gas inlet pipe 1 is arranged on the side wall of the cyclone dust collector, and a gas outlet pipe 3 is arranged inside. The upper part of the cyclone dust collector is a cylinder 2, and the middle part is The cone 11 is connected to an ash discharge pipe 7 at the bottom of the cone 11, a wind shutter 8 is arranged inside the ash discharge pipe 7, and a rotating fan blade is installed inside the wind shutter 8. The gas inlet pipe 1 is inclined at 5 degrees with the horizontal plane. The gas inlet pipe 1 is connected to the upper part of the side wall of the cylinder body 2 along the tangent direction of the cylinder body 2. The gas inlet pipe is equipped with a piece at the connection between the inner wall of the cylinder body 2 and the gas inlet pipe 1. The thickened plate 10 can effectively reduce the abrasion of the inner wall of the cylinder 2 by the dust in the gas. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com