Patents

Literature

73results about How to "Improve winnowing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

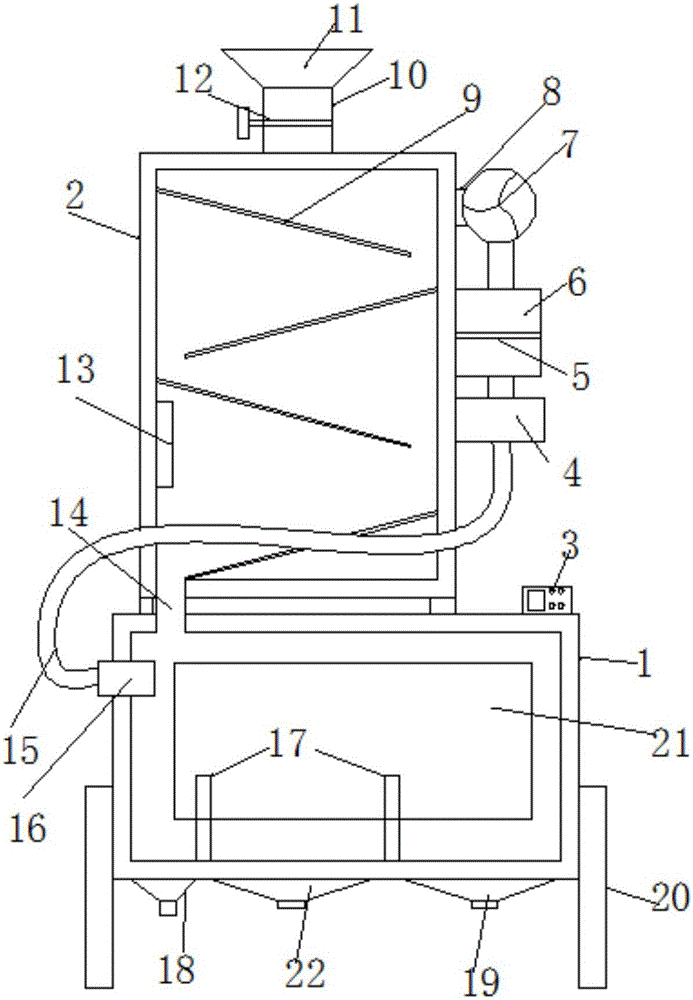

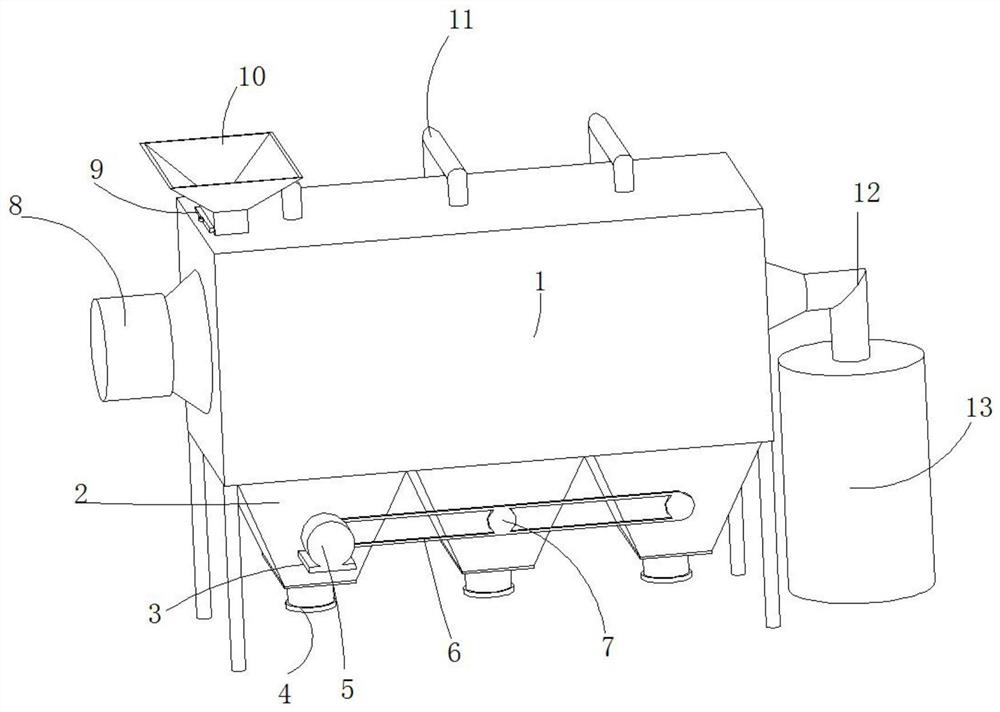

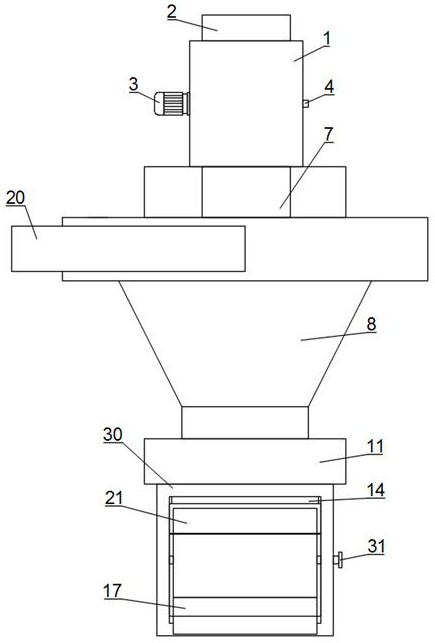

Baffling grain winnowing machine

InactiveCN106423865AReduce pollutionImprove winnowing effectGas current separationEngineeringWinnowing

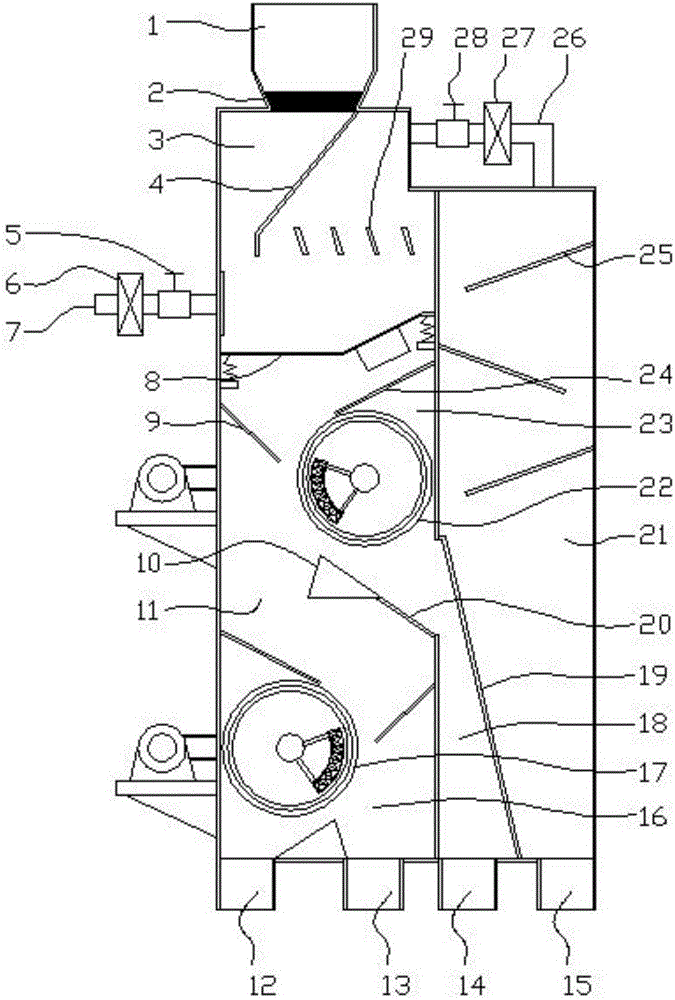

The invention discloses a baffling grain winnowing machine. The baffling grain winnowing machine comprises a support box and a turnover box, and is characterized in that the support box is a rectangular box body; support legs are symmetrically arranged on the left and right two sides of the support box; the turnover box is arranged on the left side of the upper end of the support box; a communicating pipe is arranged between the left lower end of the support box and the turnover box; the upper end of the communicating pipe is leveled with the inner bottom surface of the turnover box; a guide inclined plate is arranged at the bottom of the turnover box in a left-low and right-high manner; the left end of the guide inclined plate is leveled with the inner bottom surface of the turnover box; two separation plates are arranged at the inner bottom of the support box in parallel for dividing the support box into three collecting areas; the three collecting areas are respectively a sand grain collecting hopper, a grain collecting hopper and a dryup material collecting hopper; and the turnover box is a rectangular box body. The baffling grain winnowing machine is simple and reasonable in structure, excellent in winnowing effect and excellent in dust removing and drying effect, reduces the production cost, and is high i practicability.

Owner:郑州莉迪亚医药科技有限公司

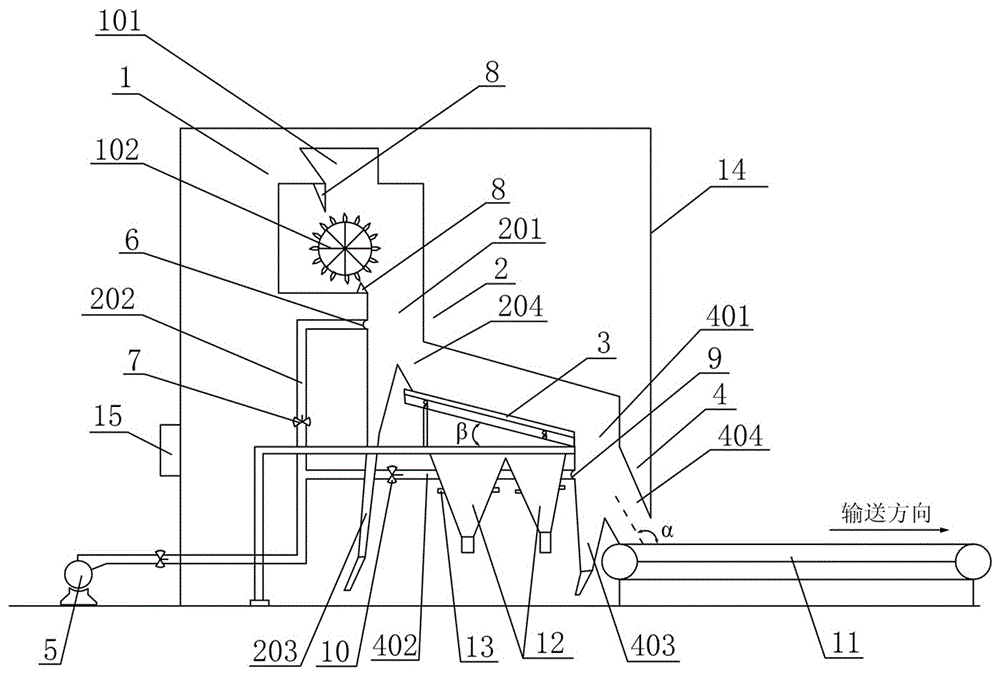

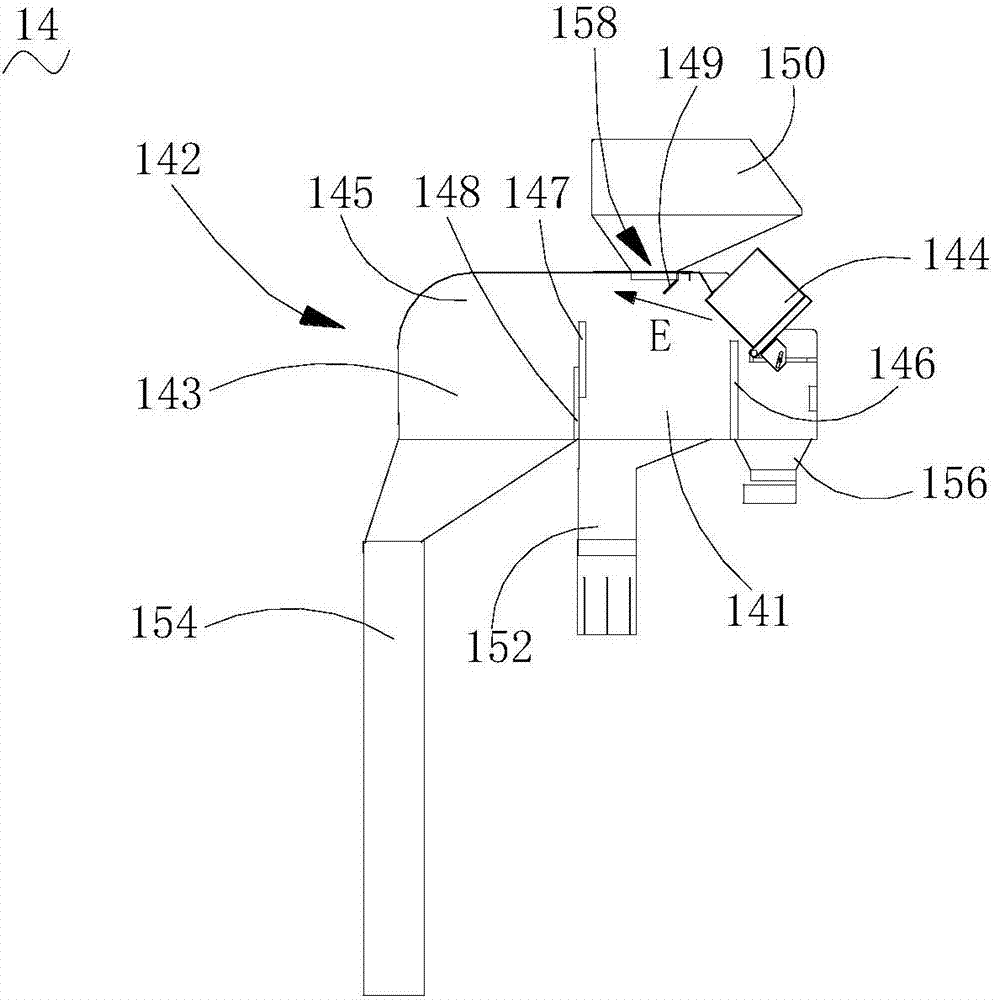

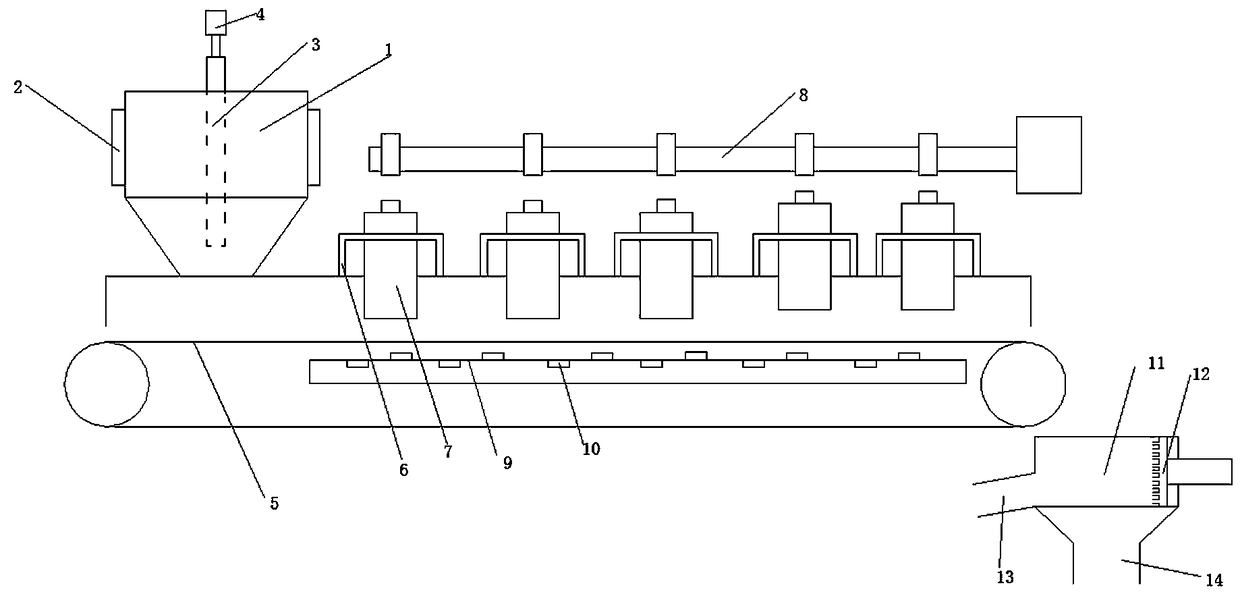

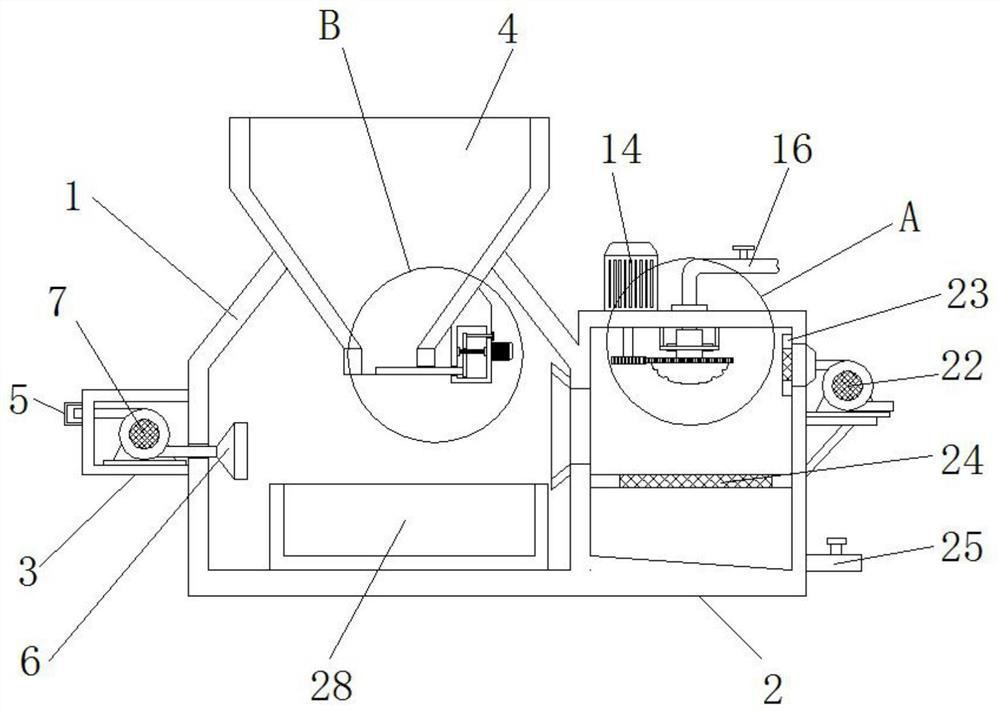

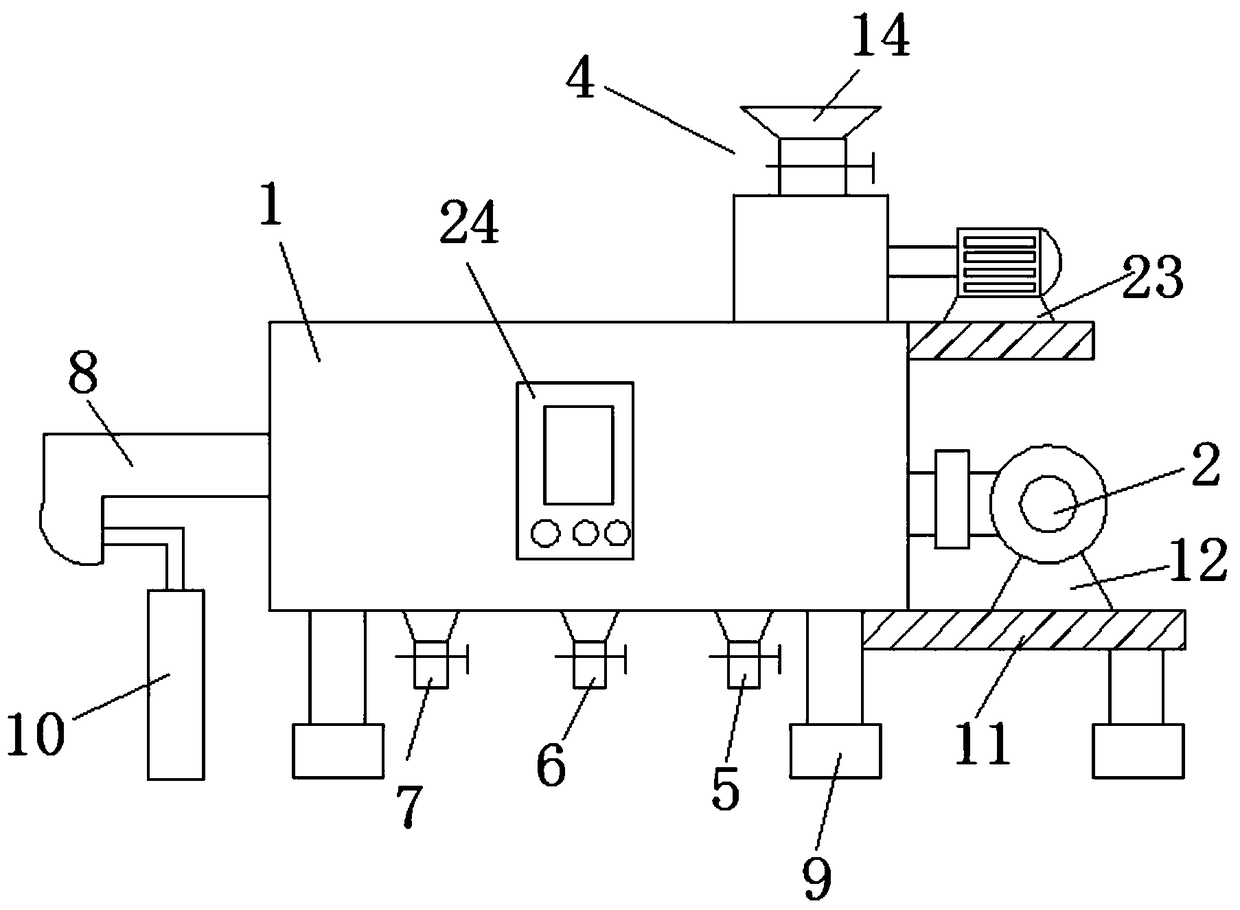

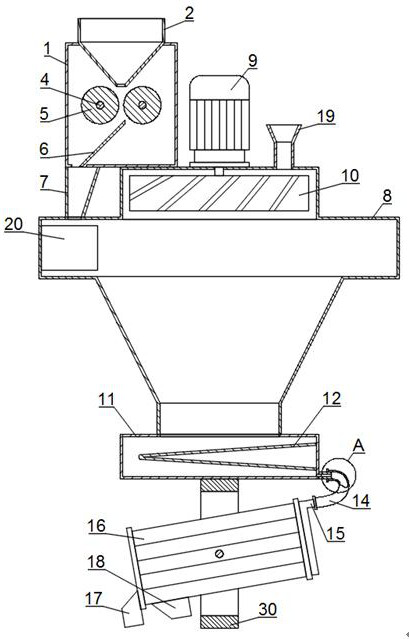

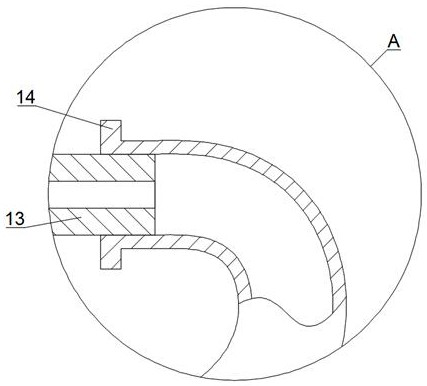

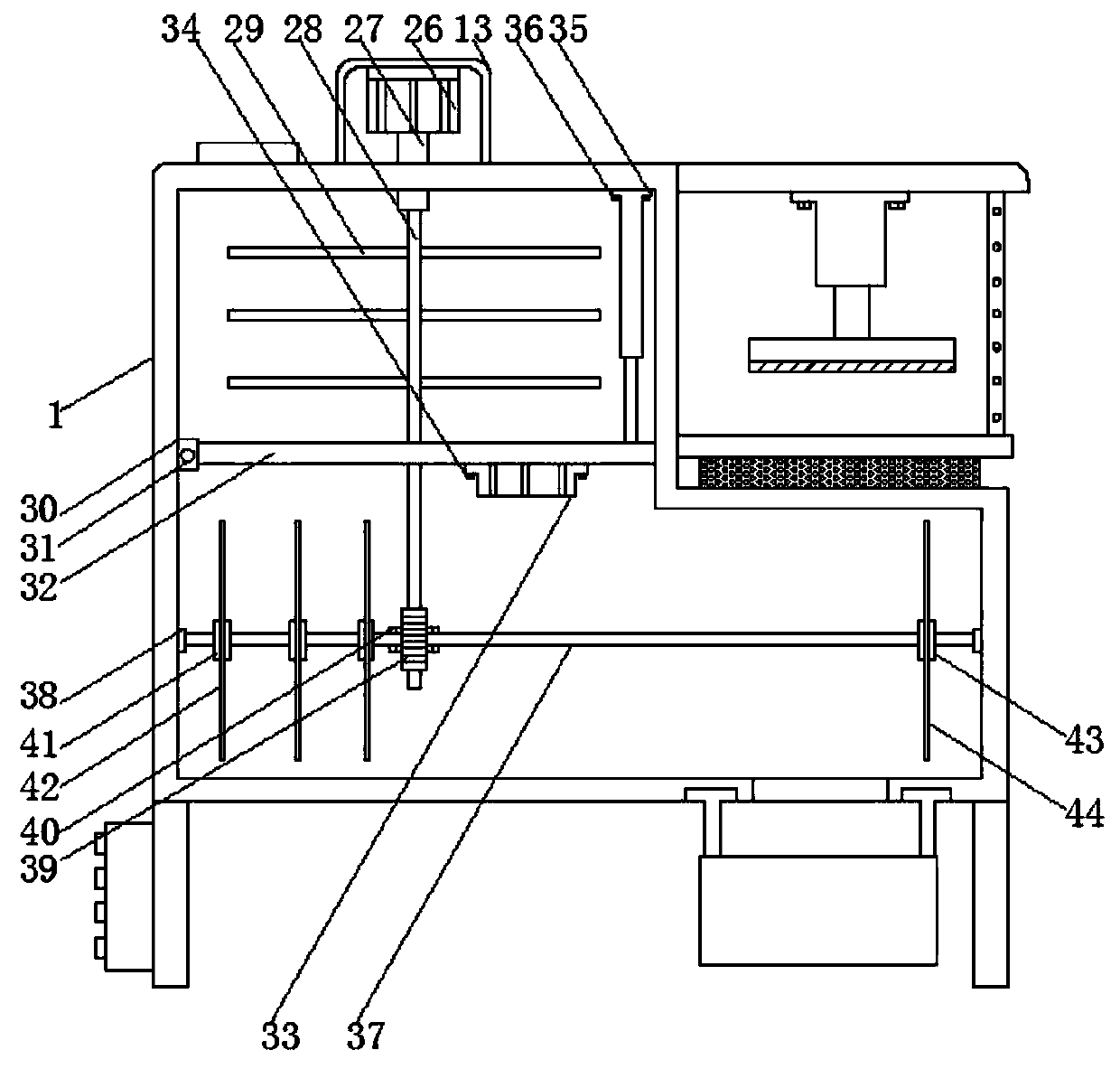

Integrative sorting machine for household garbage

PendingCN106391471AImprove sorting effectImprove sorting efficiencySievingGas current separationBrickEngineering

The invention discloses an integrative sorting machine for household garbage. The integrative sorting machine for the household garbage comprises a feeding device (1), a vibrating screen (3), a first-time winnowing device (2) and a second-time winnowing device (4). The feeding device (1) is arranged above the first-time winnowing device (2), the vibrating screen (3) is obliquely installed, the feeding end of the vibrating screen (3) is higher than the discharging end of the vibrating screen (3), the feeding end of the vibrating screen (3) is connected with the lower portion of the first-time winnowing device (2), and the discharging end of the vibrating screen (3) is connected with the second-time winnowing device (4). The integrative sorting machine for the household garbage is high in sorting efficiency, good in sorting effect, and capable of effectively relieving the manual labor intensity, and sorting, separating and recycling materials such as bricks, glass bottles, batteries, and iron blocks with the specific gravity being larger than 1.5, materials such as big block fruits with the specific gravity being about 0.8-1.5, and mud and sand.

Owner:高细平

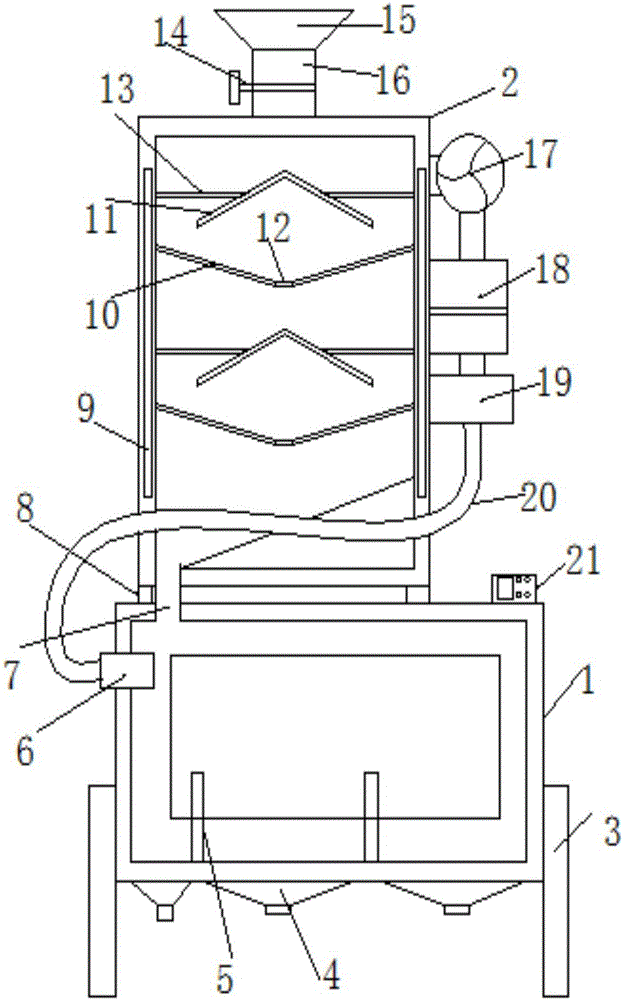

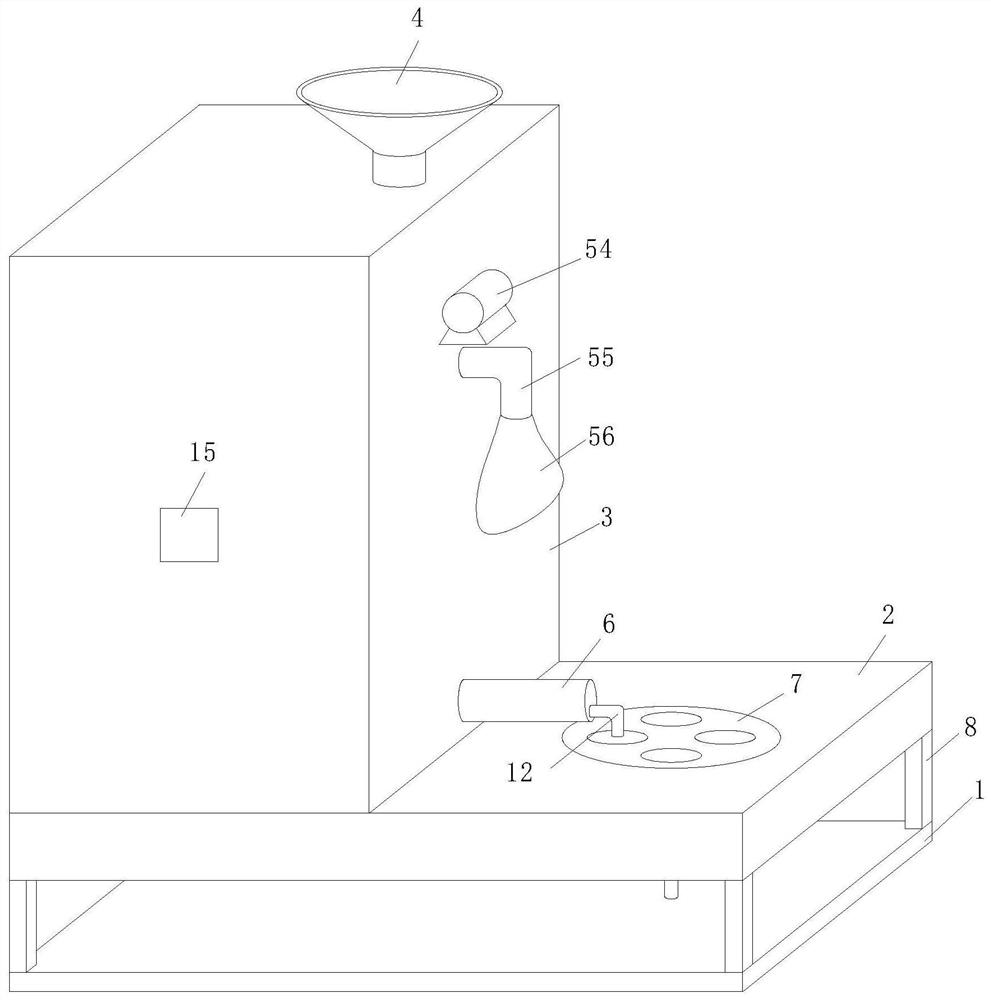

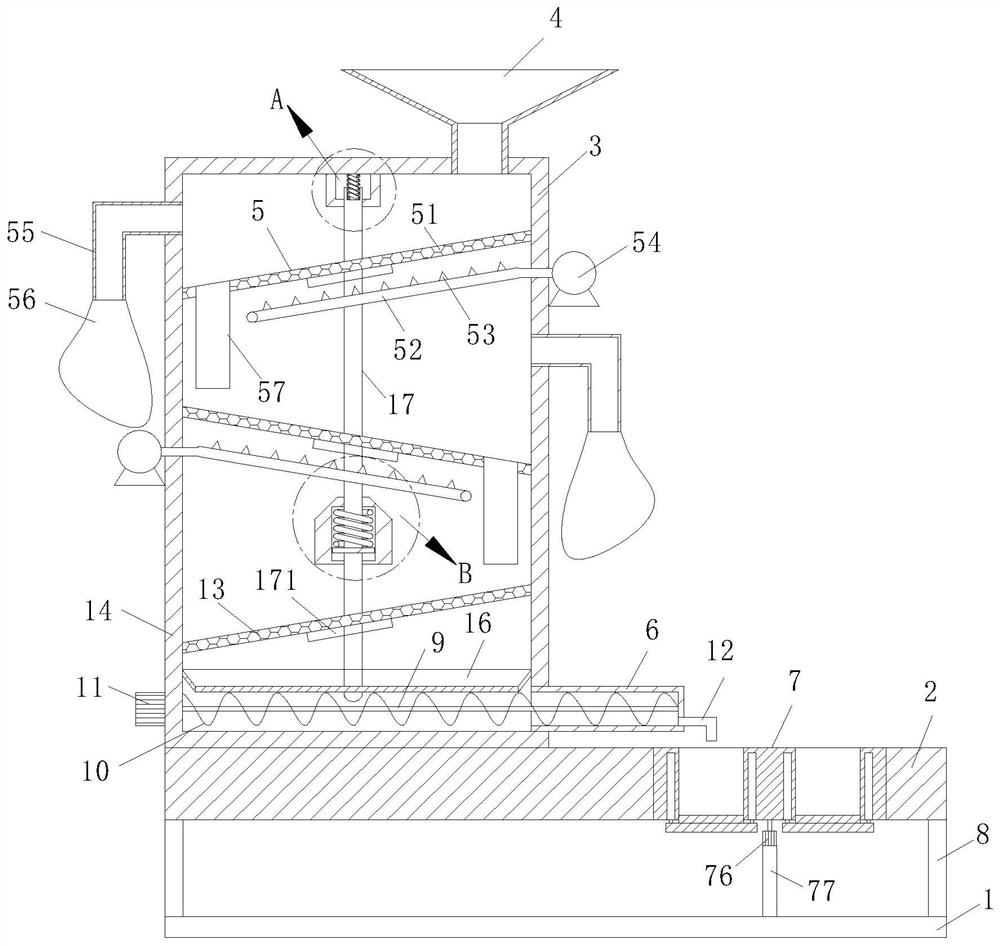

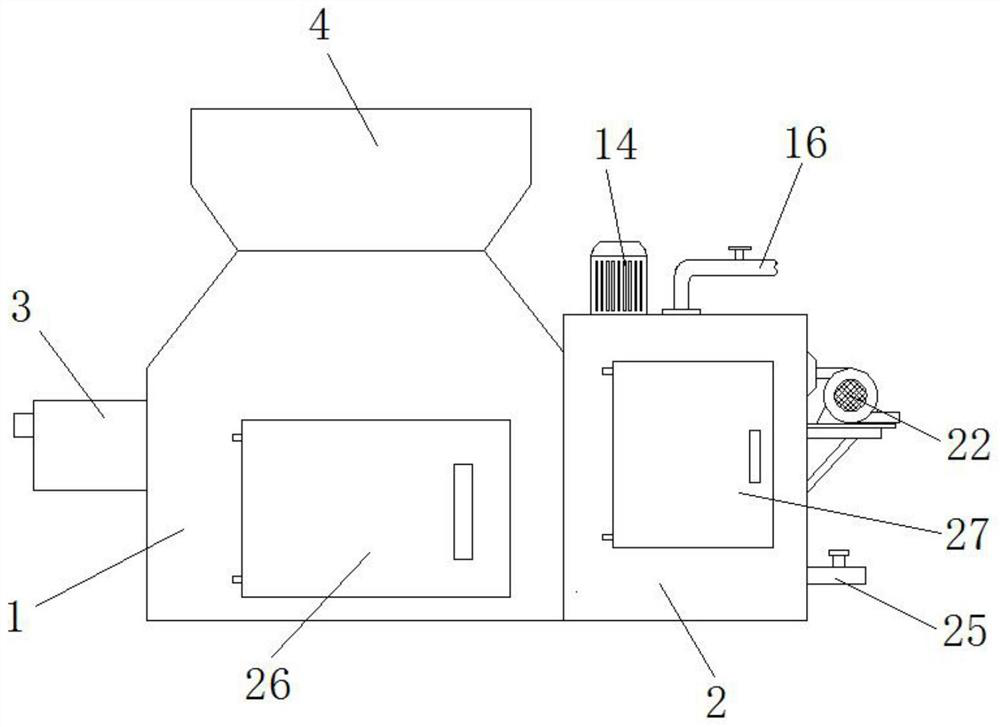

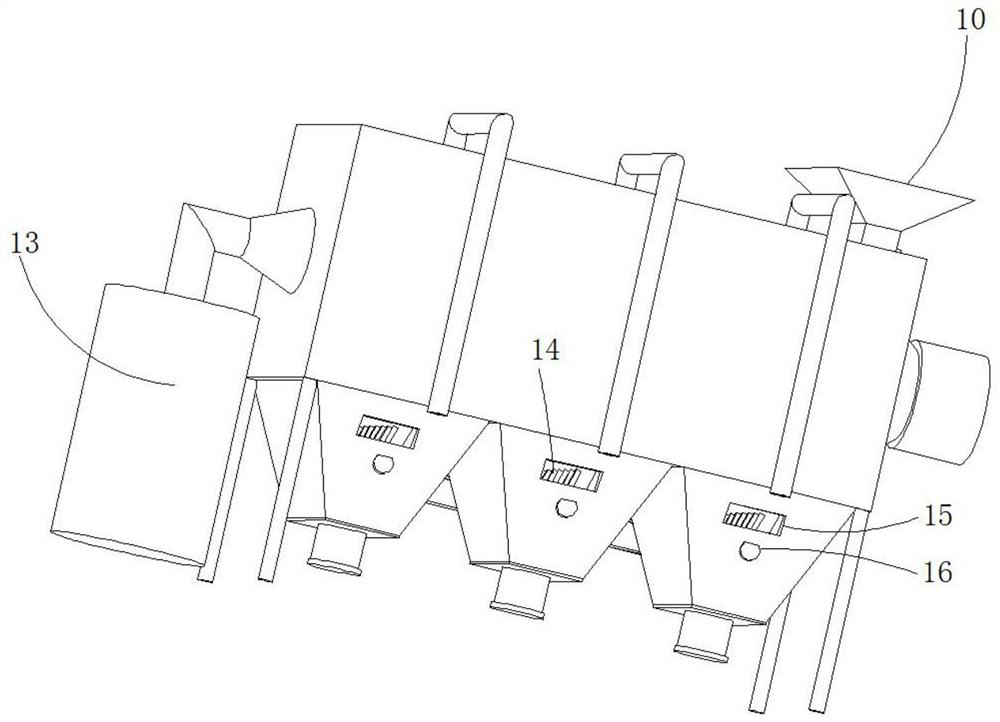

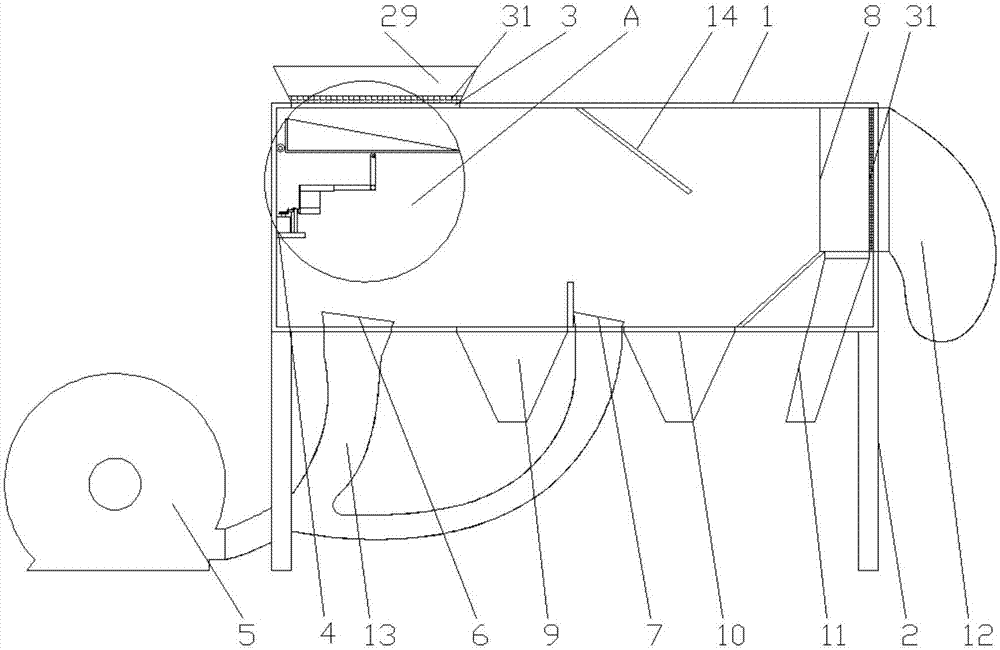

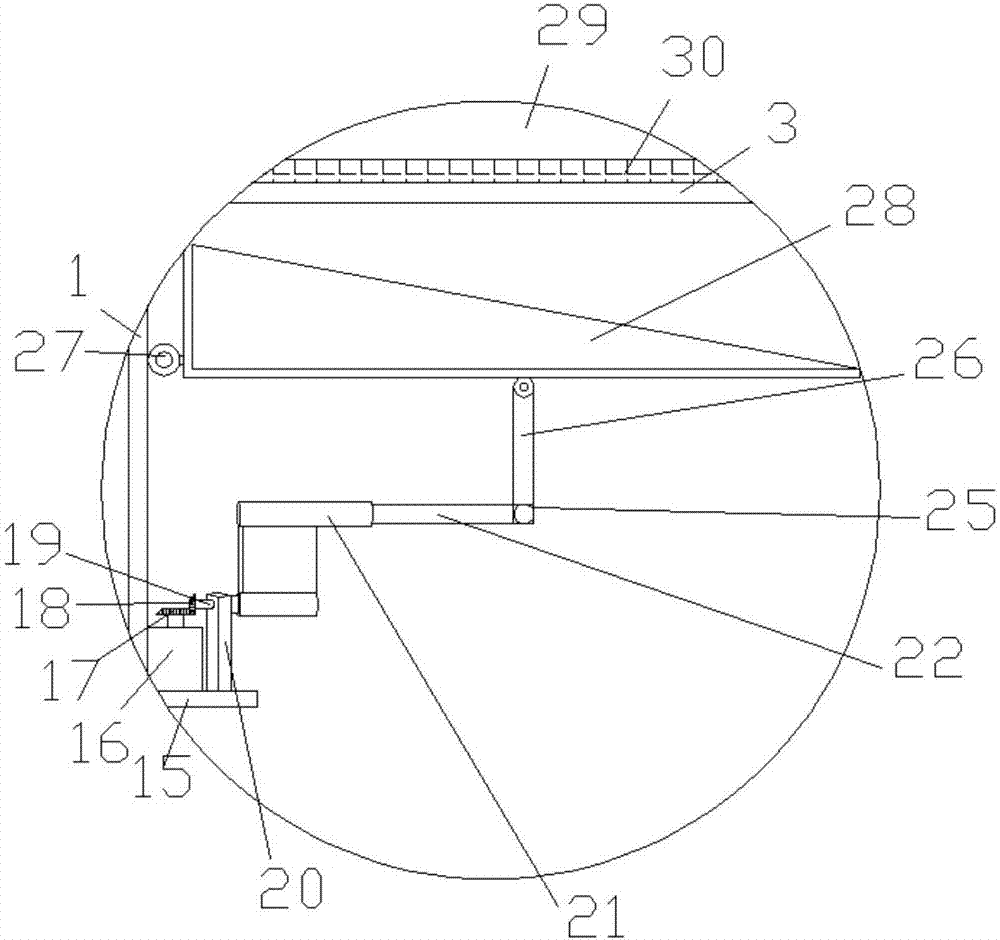

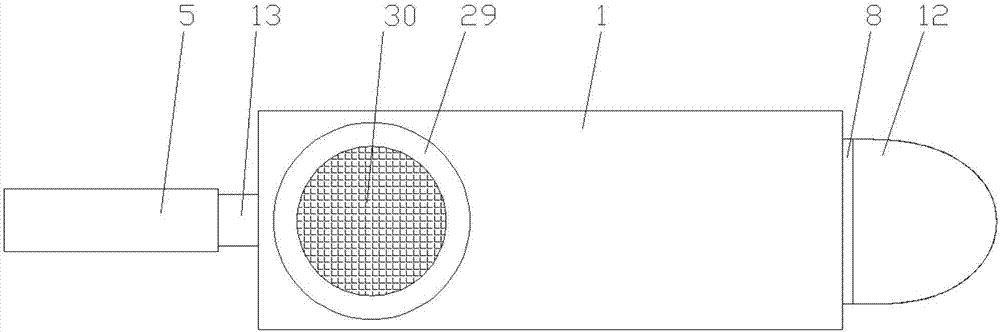

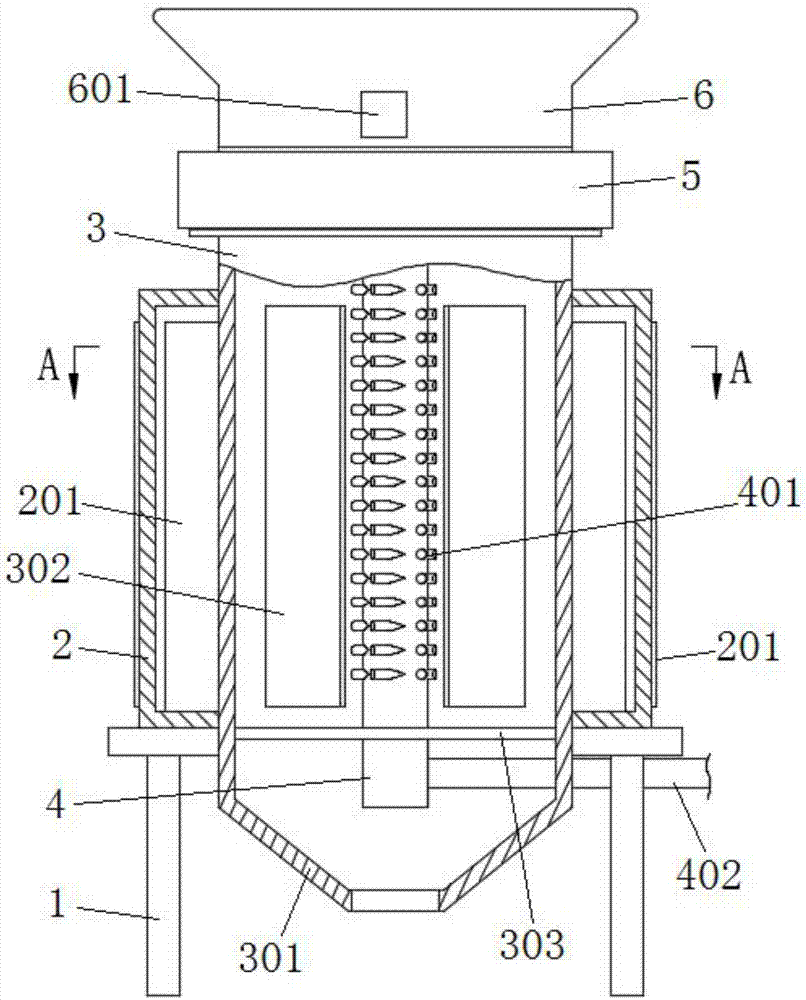

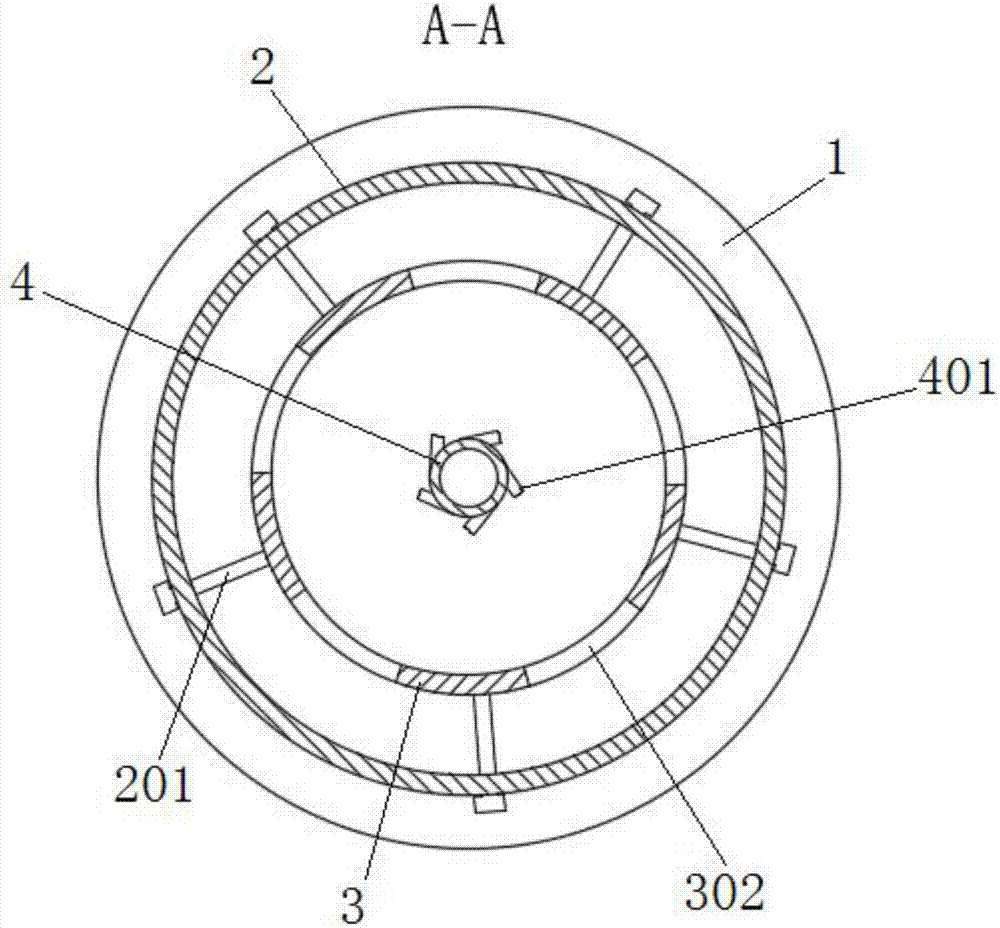

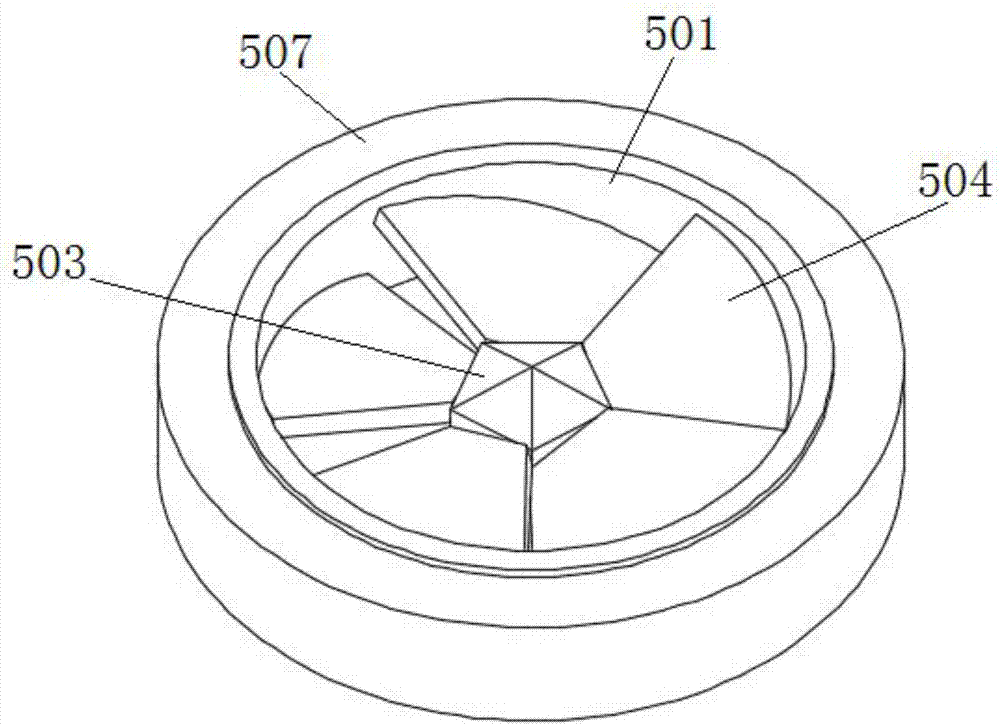

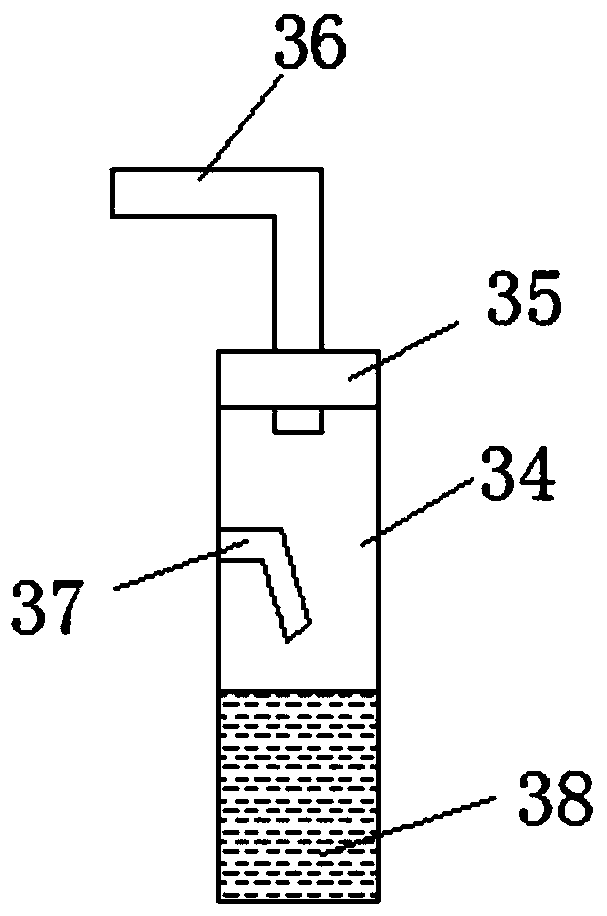

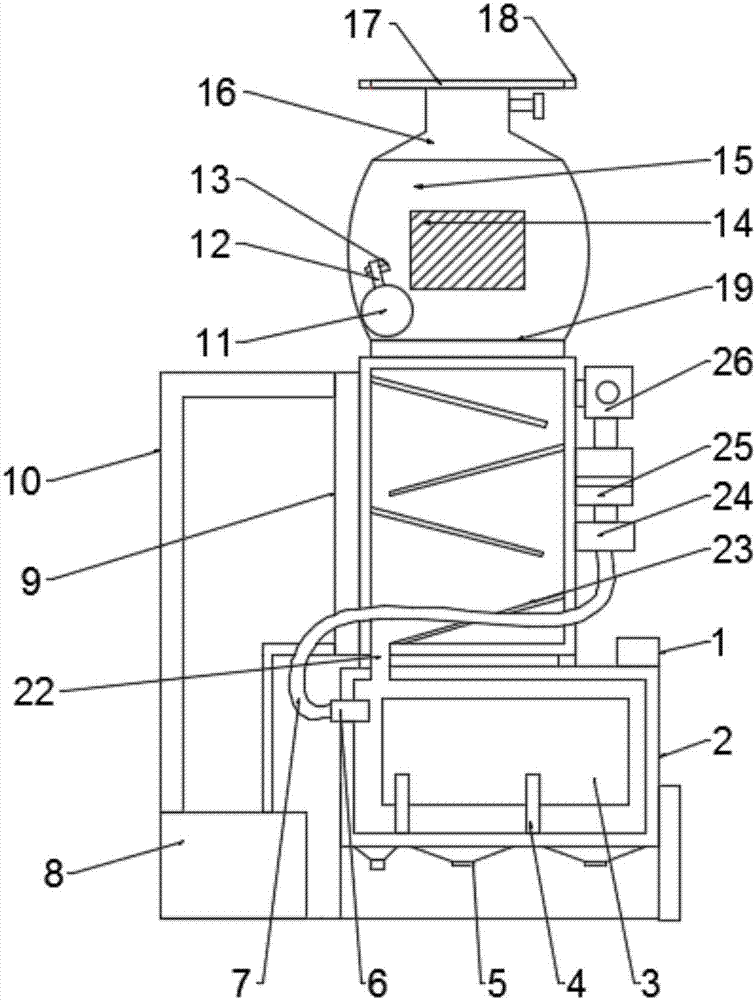

Simple agricultural grain winnowing machine

InactiveCN106423866AImprove winnowing effectSimple structureGas current separationDrying gas arrangementsAgricultural engineeringElectromagnetic heating

The invention discloses a simple agricultural grain winnowing machine which comprises a winnowing box and a de-dusting drying oven. The simple agricultural grain winnowing machine is characterized in that support legs are symmetrically arranged on left and right sides of the winnowing box; the winnowing box is arranged as a rectangular box; the de-dusting drying oven is arranged on the left side at the upper end of the winnowing box; the de-dusting drying oven is arranged as a cylindrical drum; an electromagnetic heating coil is clamped in a wall of the de-dusting drying oven; the bottom left side of the drying oven is communicated with the winnowing box through a connecting pipe; a blanking pipe is arranged in the middle of the top of the de-dusting drying oven; an adjusting valve is arranged on the blanking pipe; a feeding hopper is arranged at the upper end of the blanking pipe; a material collecting hopper is arranged in the de-dusting drying oven; an edge at the upper end of the material collecting hopper is connected with an inner wall of the winnowing box; a blanking hole is formed in a middle position at the lower end of the material collecting hopper; and a material distributing hopper is arranged above the material collecting hopper. The simple agricultural grain winnowing machine has the advantages of simple and reasonable structure, good winnowing effect, good de-dusting and drying effects, capability of reducing production cost of the device and high practicability.

Owner:郑州莉迪亚医药科技有限公司

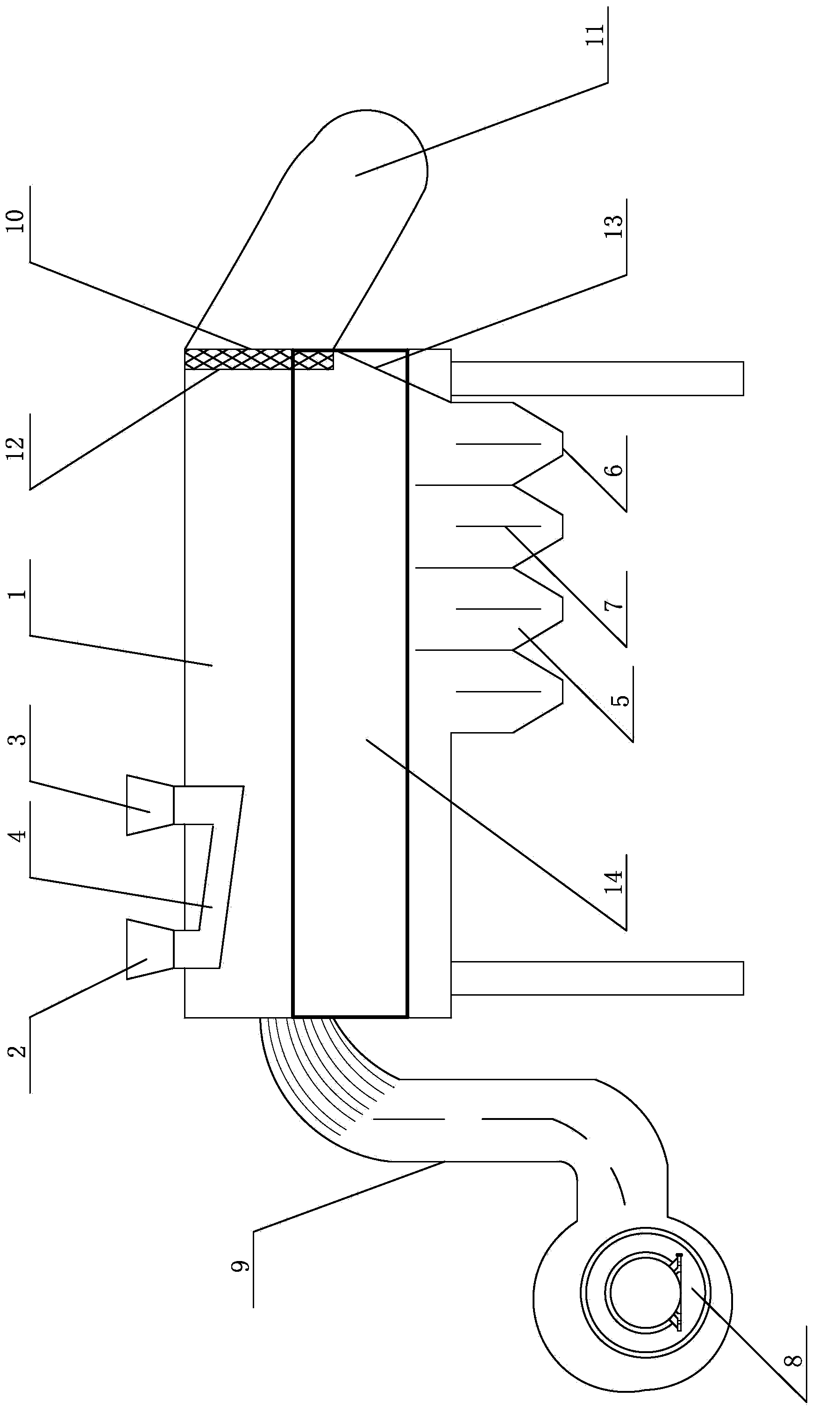

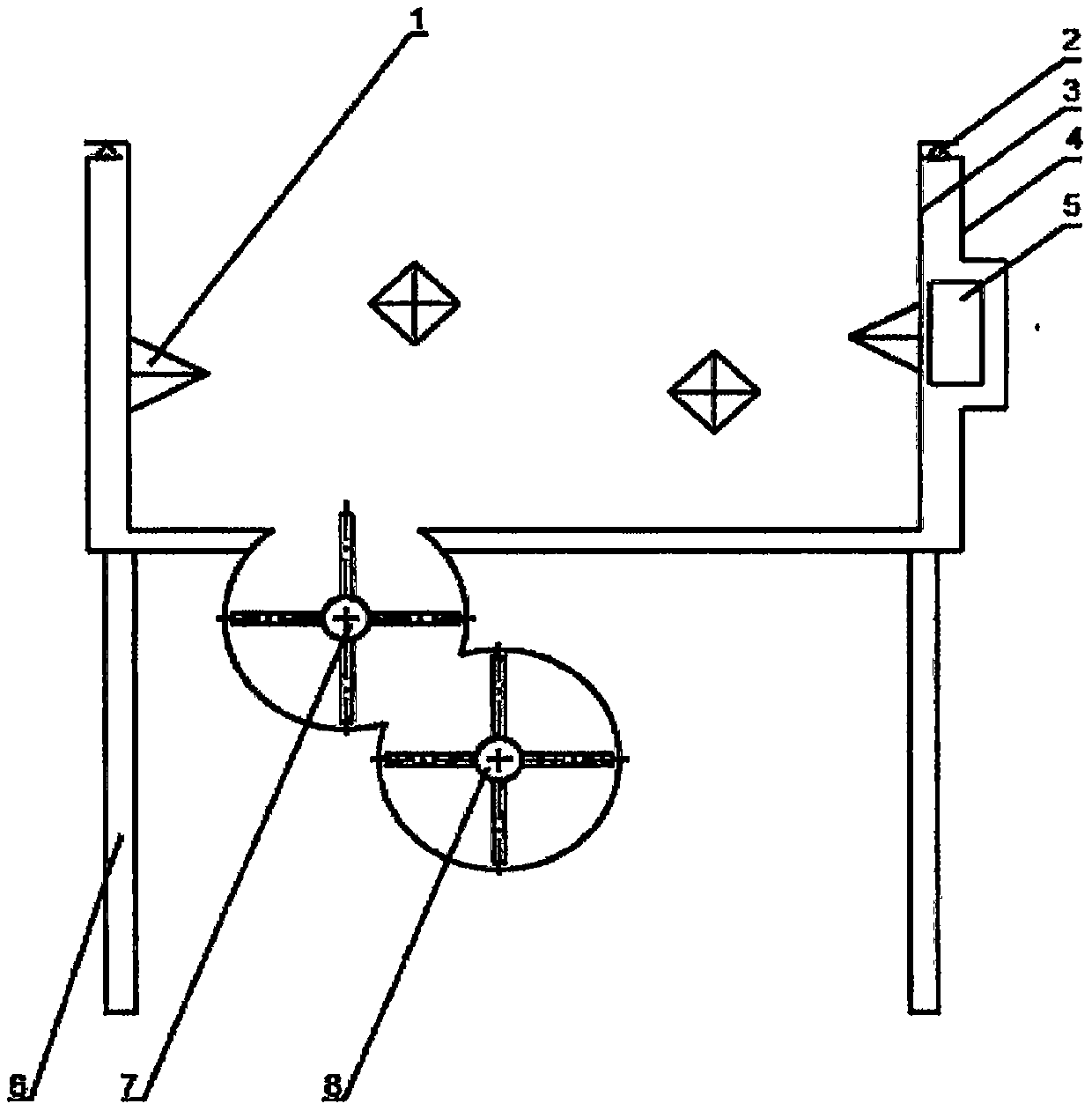

Tea winnowing machine

InactiveCN104259101AEliminate the phenomenon of vortexImprove winnowing qualityGas current separationAgricultural engineeringTea leaf

The invention discloses a tea winnowing machine. The tea winnowing machine comprises a winnowing chamber and a fan; a feeding opening and a returning opening are arranged in the top part of the winnowing chamber and are communicated with each other through a screening device, wherein the screening device is equipped with an oscillator; the left side of the winnowing chamber is connected with the fan through an S-shaped pipeline; the mounting position of an air opening of the S-shaped pipeline is lower than that of the screening device; a dust discharging opening is arranged in the right side of the winnowing chamber and is connected with a dust recovering bag; a plurality of tea discharging buckets are arranged at the bottom part of the winnowing chamber; tea discharging openings are formed in the bottom parts of the tea discharging buckets; vortex type rotating plates which are vertically positioned in the centers of the tea buckets are fixedly mounted above the tea discharging openings; an observing window is mounted in the front side of the winnowing chamber. The tea winnowing machine is simple in structure and easy to be implemented; the air speed is uniform and stable; the winnowing quality is high; the waste and pollution are avoided; the tea winnowing machine is specially applied to tea winnowing.

Owner:GUILIN TECH ENTERPRISE DEV CENT

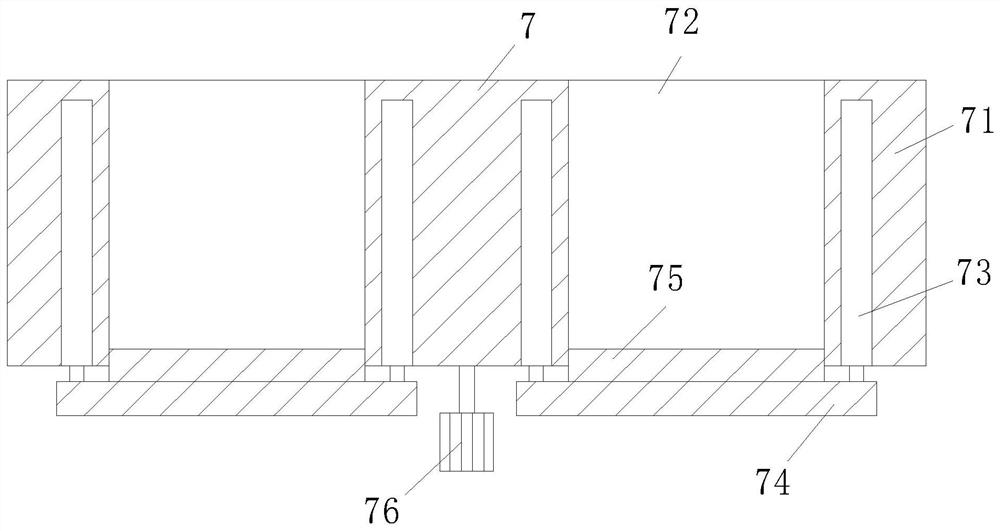

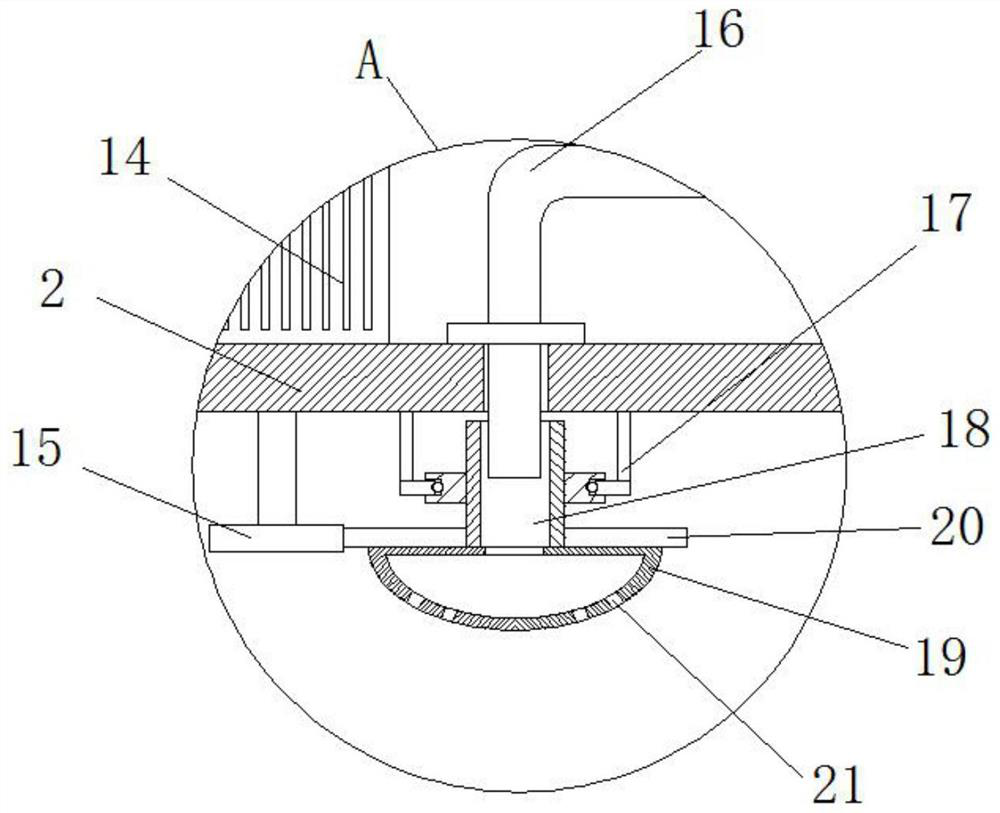

Rice automatic bagging equipment with function of dust extraction and purification

InactiveCN111687048AWith dust and impurity removal functionDelay winnowing flow rateSievingGas current separationControl engineeringDust control

The invention discloses rice automatic bagging equipment with function of dust extraction and purification. The equipment includes a base plate, a base, and a purification box, four corners of the topend of the base plate are fixedly connected with four corners of the bottom end of the base respectively through four stand columns, a feed hopper is fixedly arranged on the other side of the top endof the purification box, a discharging drum is fixedly connected with the bottom end of the other side of the purification box in a penetrating mode, an auger shaft is arranged in the discharging drum in a rotating mode, an auger leaf matched with the discharging drum is fixedly arranged on the auger shaft, and a discharging pipe is fixedly connected with the bottom of one end of the dischargingdrum. The auger leaf on the auger shaft is driven to carry out quantitative transporting through a servo motor, automatic charging can be carried out through the coordination of the discharging pipe and a bagging assembly, the manual bagging is not needed, the production cost is reduced, and the production efficiency is improved. Kinetic energy of the servo motor can be utilized repeatedly througha transmission mechanism, the kinetic energy can be transferred to the transmission mechanism so that the transmission mechanism drives a mesh plate to vibrate, and rice is convenient to discharge quickly.

Owner:颍上县金波米业股份有限公司

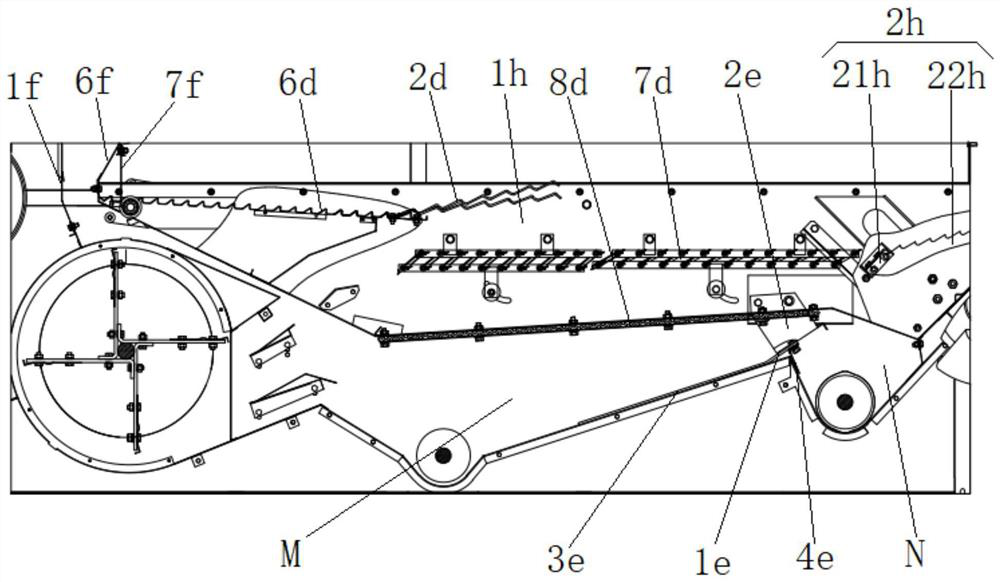

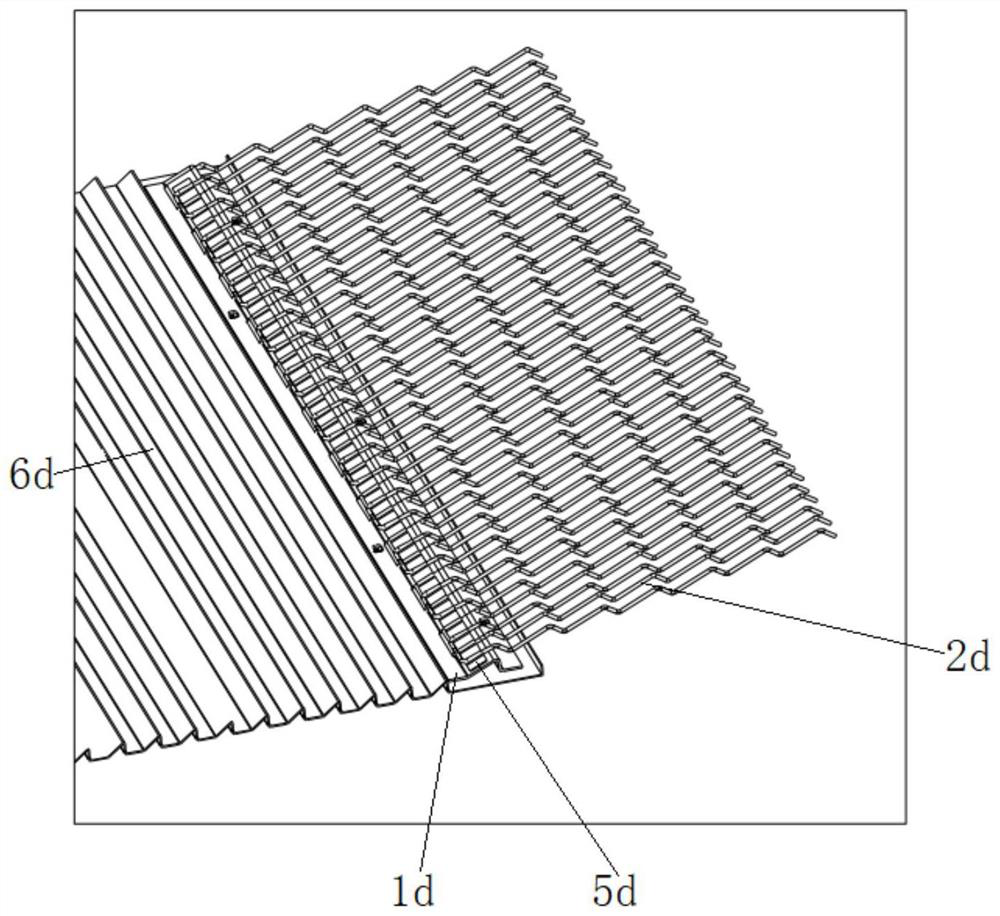

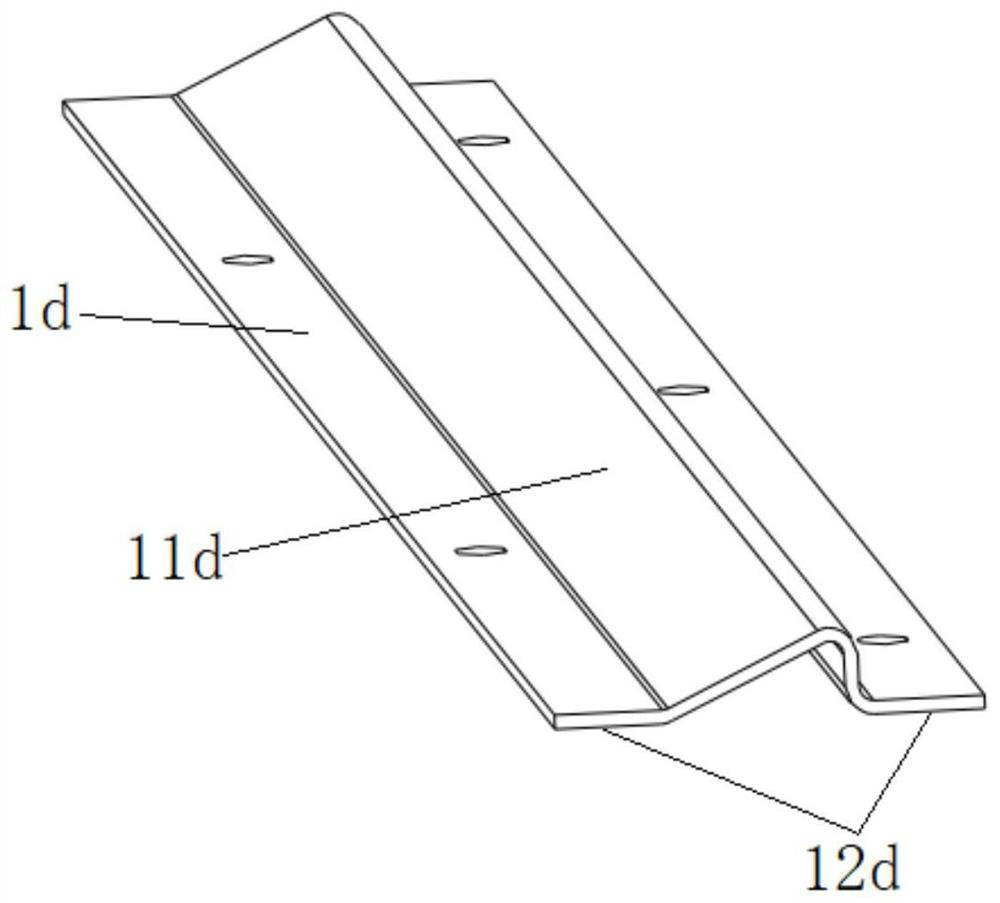

Screening system and combine harvester

PendingCN112690107AAvoid wastingPrevent throwingMowersThreshersAgricultural scienceAgricultural engineering

The invention provides a screening system and a combine harvester. The screening system comprises a vibrating screen, a front sealing structure, a grain separating structure and a driving structure. The vibrating screen is provided with an upper screen area and a lower screen area, a lifting structure is arranged at the tail end of a corrugated plate in the upper screen area to increase the fall between the corrugated plate and a scaly screen, two-section lifting is formed in cooperation with a tail screen at the tail end, clustered crops are fully shaken to be scattered and loosened, and waste caused by the fact that crop straw carries grains to be discharged is avoided. Meanwhile, the front sealing structure is arranged at the front end of the corrugated plate to prevent the grains from being thrown out by the vibrating screen. The grain separating structure is arranged at the position, between a grain collecting area and an impurity collecting area, below the vibrating screen, so that clean grains are effectively separated from impurities such as straw, the grains are collected more completely and cleanly, waste is avoided, and the screening efficiency is improved.

Owner:JIANGSU WORLD AGRI MACHINERY

Iron removal mineral separation device used for feldspar quarry

ActiveCN106423551AImprove product qualityAvoid pollutionVortex flow apparatusMagnetic separationParticulatesEngineering

The invention discloses an iron removal mineral separation device used for feldspar quarry. The device comprises a feeding hopper, a winnowing chamber, a feeding baffle, a first pressure adjusting valve set, an air blower, an air inlet pipeline, a vibration screening module, a magnetic separation guide plate, a triangular guide module, a second-level magnetic separation chamber, a second magnetic separation mechanism, a magnetic material channel, a partition plate, a guide block, a dust fall chamber, a first magnetic separation mechanism, a first-level magnetic separation chamber, a magnetic separation block plate, a dust fall module, an air outlet pipeline, an exhaust fan, a second pressure adjusting valve set, a windowing guide plate and the like. The characteristic that after broken feldspar quarry and ferric oxide are separated, the sizes and the weights of particulate matter are different is used for successively carrying out windowing, first-level magnetic separation and second-level magnetic separation, a flotation agent does not need to be added, the corrosion and the damage of the traditional flotation manner to the feldspar quarry are avoided, due to multi-level impurity removal, most of ferric oxide and other magnetic separation impurities are separated, the quality of feldspar quarry is improved, in addition, the device carries out degradation on dust, and environment is protected.

Owner:湘潭中韩长石矿业有限公司

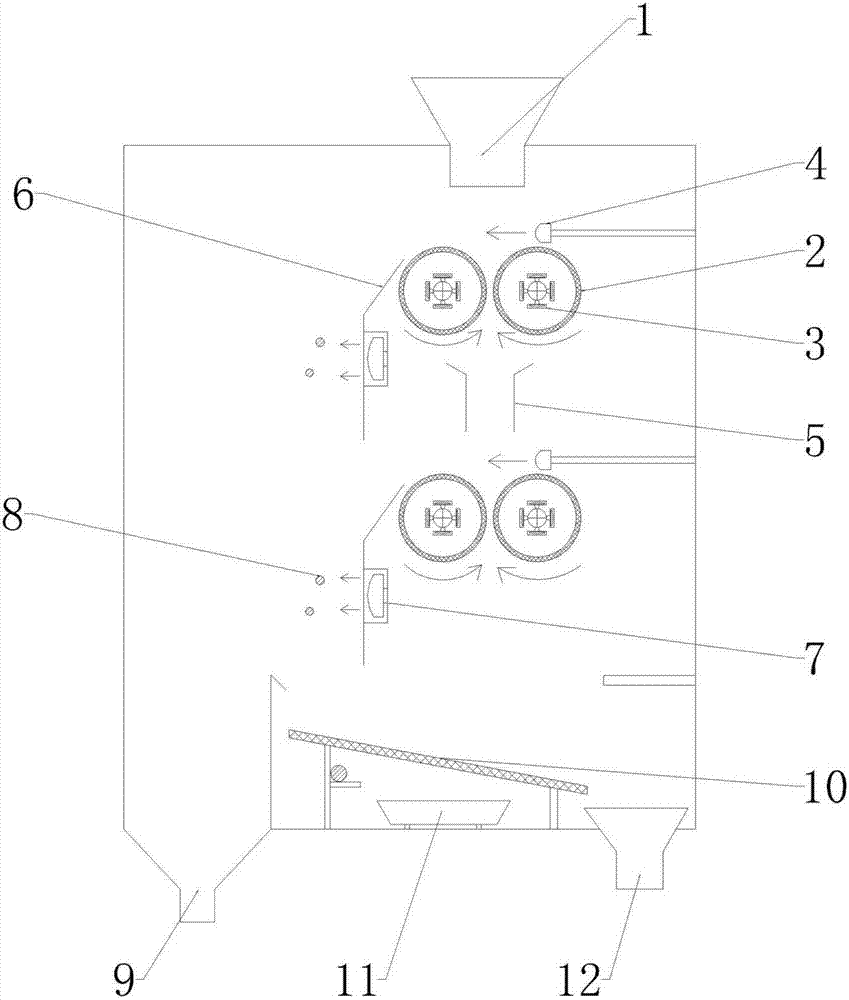

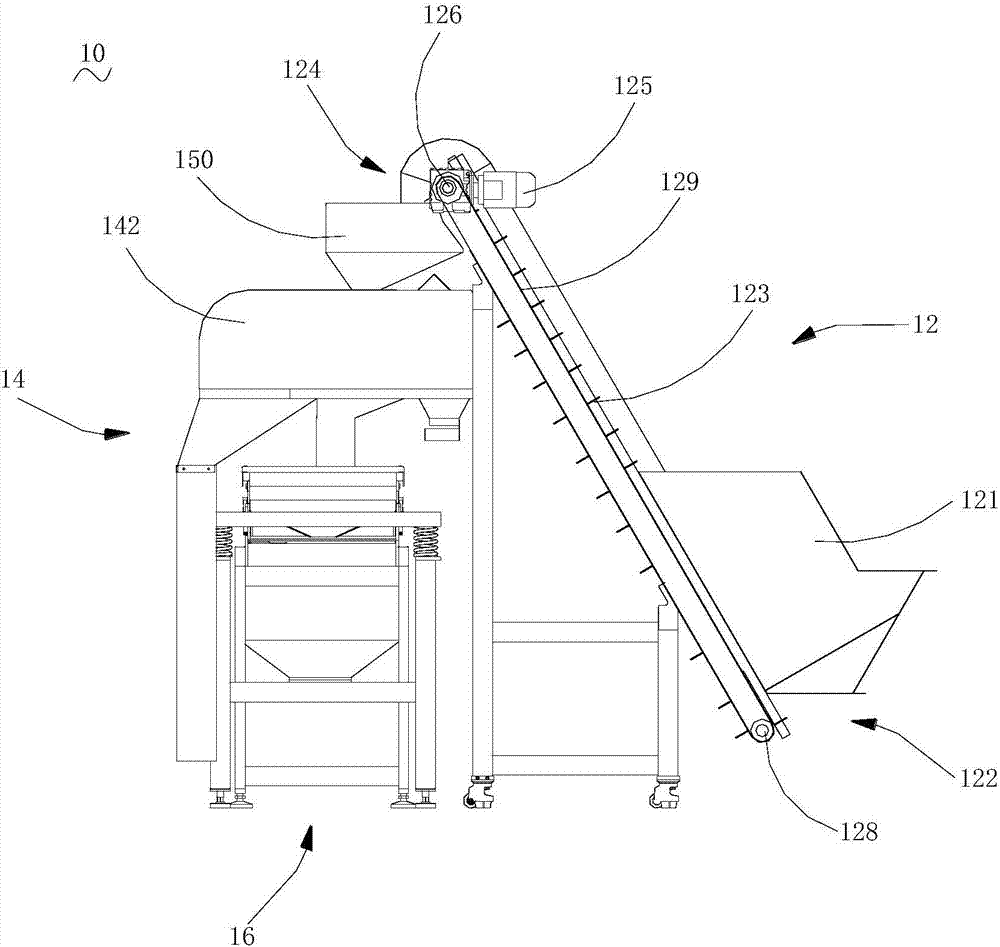

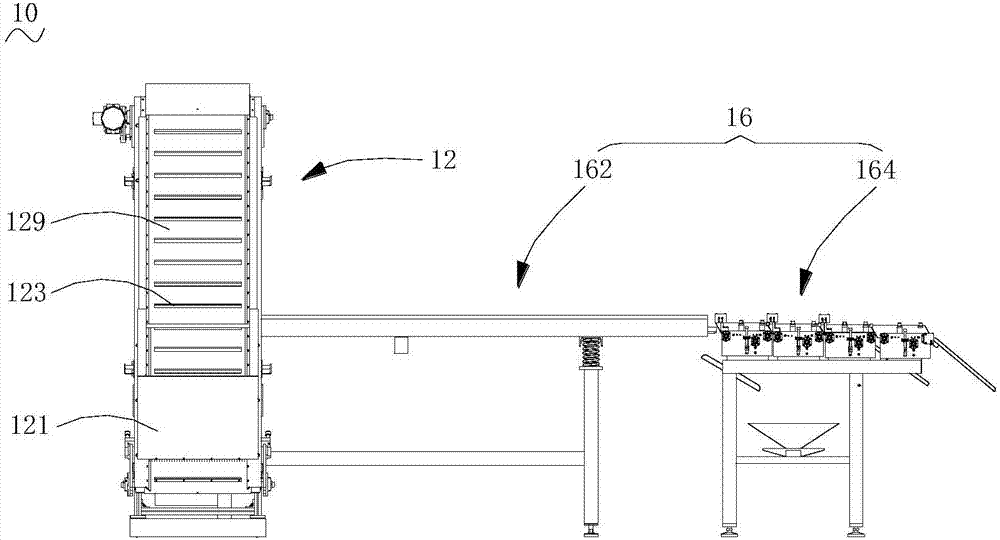

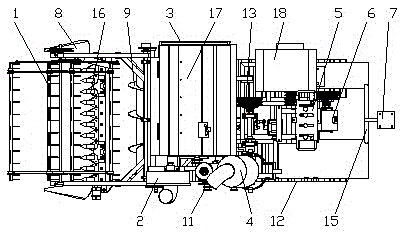

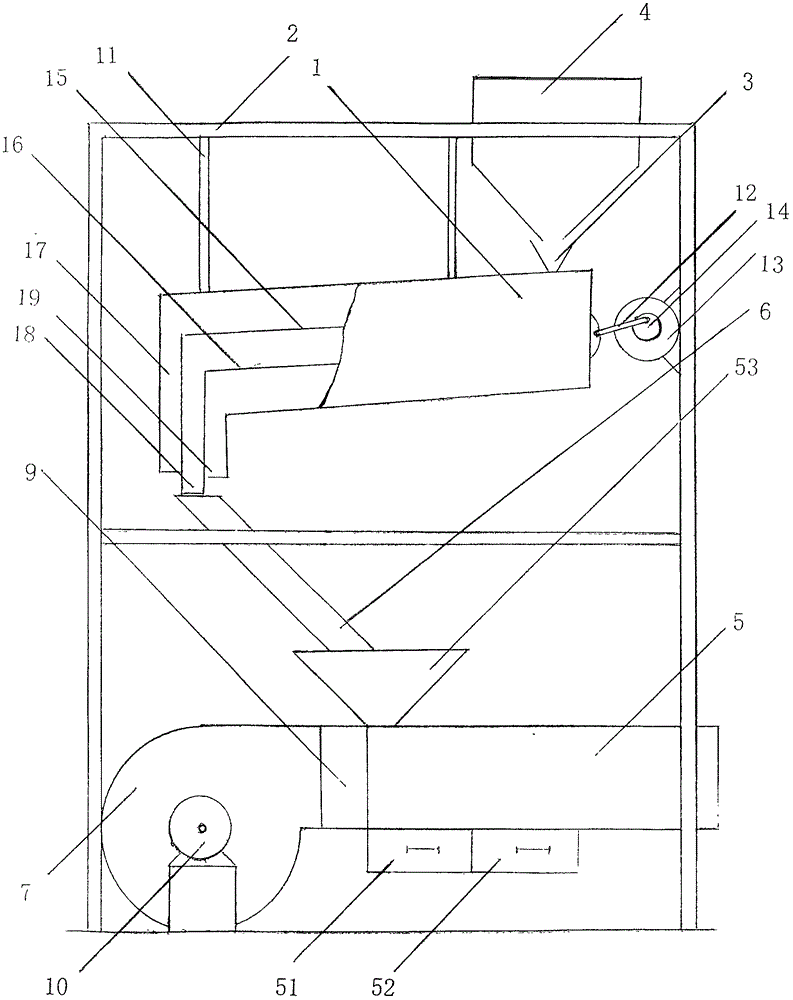

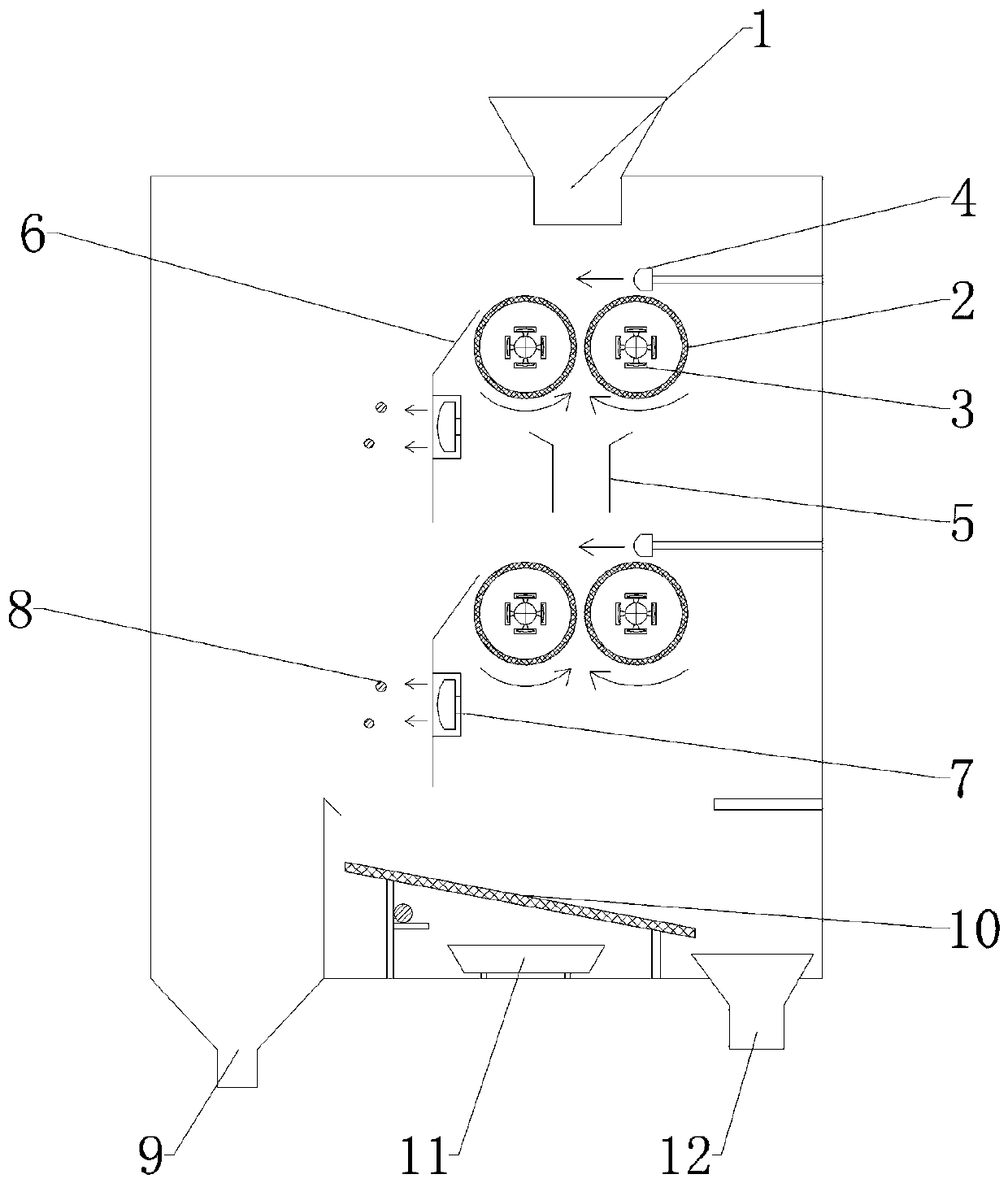

Coarse filtering system for rice finish processing

InactiveCN107377388AImprove winnowing effectAchieve separationGas current separationFilter systemBran

The application discloses a coarse filtering system for rice finish processing and belongs to the technical field of grain processing. The coarse filtering system comprises a feeding bin, a screening bin and a discharging bin connected from top to bottom in sequence. A first winnowing chamber and a second winnowing chamber which are arranged from left side to right side and communicated with each other are arranged in the screening bin. Two roller winnowing mechanisms arranged at an interval and aligned up to down are arranged in the first winnowing chamber. Each roller winnowing mechanism comprises two rollers arranged left to right in parallel; the two rollers are both connected with the first winnowing chamber rotationally and driven by motors; a plurality of first fans in circular arrangement are arranged in the rollers; the rollers are provided with a plurality vent holes; secondary fans with horizontal air discharging are arranged above the rollers. Two third fans are arranged in the second winnowing chamber. A rice discharging chamber and a bran discharging chamber are arranged in the discharging bin. By the innovative structural design, thorough separation of rice and bran is achieved, which brings convenience to rice processing and bran collecting at the later period.

Owner:安徽宏虎粮油股份有限公司

Waste cigarette pneumatic separation device and cigarette separation system

ActiveCN106955845AWinnowingAct as a barrierSievingGas current separationBlock effectSeparation system

The invention relates to a waste cigarette pneumatic separation device and a cigarette separation system. The waste cigarette pneumatic separation device comprises an air bellow and an air blowing device. A partition plate is arranged in the air bellow to divide an inner cavity of the air bellow into a first pneumatic separation cavity, a second pneumatic separation cavity and a pneumatic separation channel. The air bellow is provided with a feed inlet for achieving feeding from the first pneumatic separation cavity. An air flow port of the air blowing device faces towards the feed inlet. Air flow flows through the pneumatic separation channel in the feeding direction to enter the second cavity. In the pneumatic separation process, defective or waste cigarettes falling into the air bellow from the feed inlet are blown to be dispersed under the effect of pneumatic separation air flow, and air flow continues to be flow to drive the defective or waste cigarettes to flow along the pneumatic separation channel. The first partition plate achieves a blocking effect, and defective or waste cigarettes in various states are blocked to fall into the first pneumatic separation cavity. Cut tobaccos and paper scraps are relatively light and continue to move along the pneumatic separation channel rather than being blocked by the first partition plate and falling into the second pneumatic separation cavity, accordingly, pneumatic separation for defective or waste cigarettes is achieved, the pneumatic separation effect is good, production efficiency is high, and the cost is low.

Owner:CHANGDE RUIHUA MFG

Slab abrasive belt rice mill

InactiveCN108405030AEffective contactEasy to shellGrain huskingGrain polishingMilling cutterElectric machinery

The invention discloses a slab abrasive belt rice mill. The slab abrasive belt rice mill comprises a hopper, an abrasive belt is arranged below the hopper, a cover body is arranged on the abrasive belt and provided with a plurality of cutting blade brackets, and a rice milling cutter is slidably arranged on each cutting blade bracket; the distance between the rice milling cutters and the abrasivebelt is gradually increased from the hopper to the discharging direction of the abrasive belt; the middle of the abrasive belt is provided with a supporting plate, and convex and concave blocks are arranged on the supporting plate; a cam shaft which is driven by a motor to rotate is arranged above the cover body; one end of the abrasive belt is provided with a winnowing box; one side of the winnowing box is provided with a bran discharging pipeline, and the other side of the winnowing box is provided with an air exhaust pipeline connected with an air blower; and the lower end of the winnowingbox is provided with a discharging outlet. The slab abrasive belt rice mill can effectively complete the rice milling procedure, the temperature of rice in the rice milling procedure is not high, thefollow-up polishing work is not influenced, in addition, the hulling speed is high, and the smashed rice amount is small.

Owner:常州市武进双湖粮油机械股份有限公司

Adjustable-power strong wind impurity removal device

InactiveCN105170461AReduce pollutionImprove working environmentGas current separationWorking environmentEngineering

The invention relates to an adjustable-power strong wind impurity removal device which is arranged at the tail end of a mixed material conveying belt. The impurity removal device comprises a vibrating feeder and a variable-frequency fan. A material inlet of the vibrating feeder is formed below the tail end of the mixed material conveying belt and used for receiving fallen mixed materials. A material outlet of the vibrating feeder extends into a sorting chamber. An air outlet of the variable-frequency fan extends into the sorting chamber. The air outlet direction of the air outlet faces the material outlet of the vibrating feeder. The upper end of the sorting chamber is connected with a dust pipeline. A spraying device is arranged in the dust pipeline. The variable-frequency fan is an adjustable-power vertical airflow winnowing machine. The variable-frequency vertical airflow winnowing machine is arranged at the tail end of the conveying belt, light materials and heavy materials in the mixed materials can be sorted effectively, all the dust in an outlet pipe is collected, dust pollution is reduced, and the working environment of workers is improved.

Owner:南京雨花再生资源有限公司

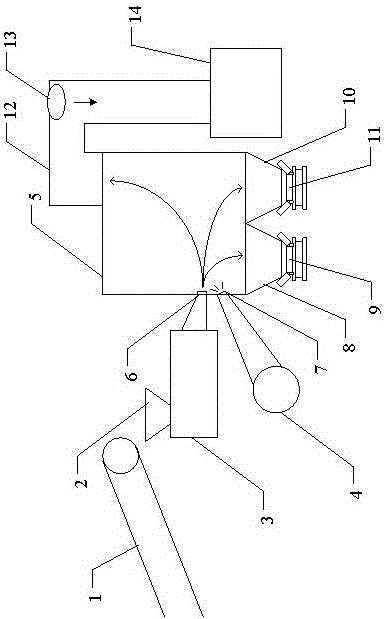

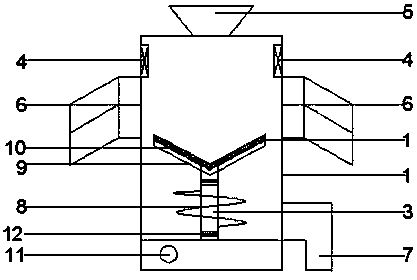

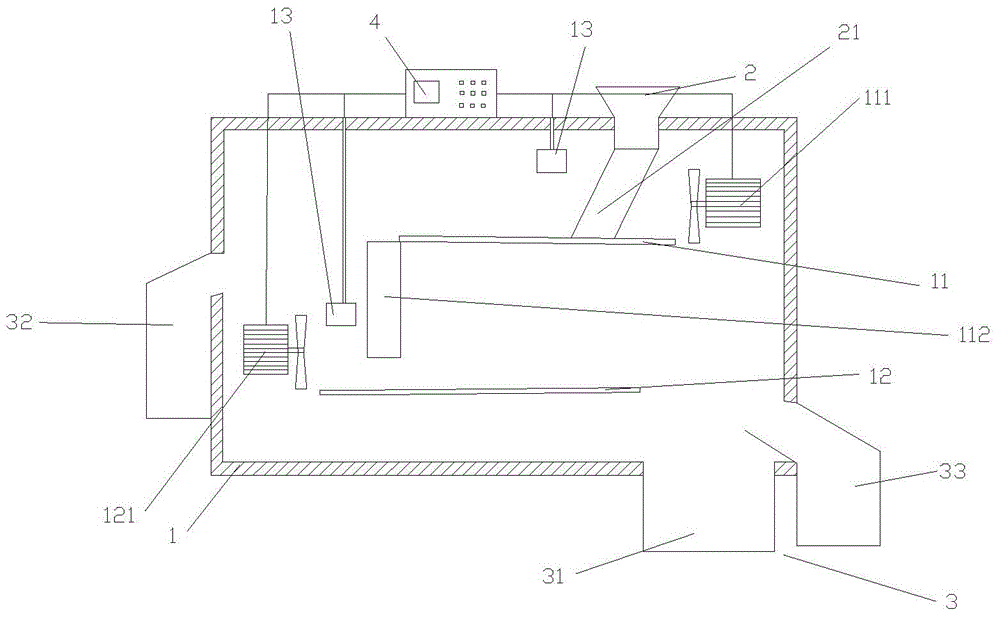

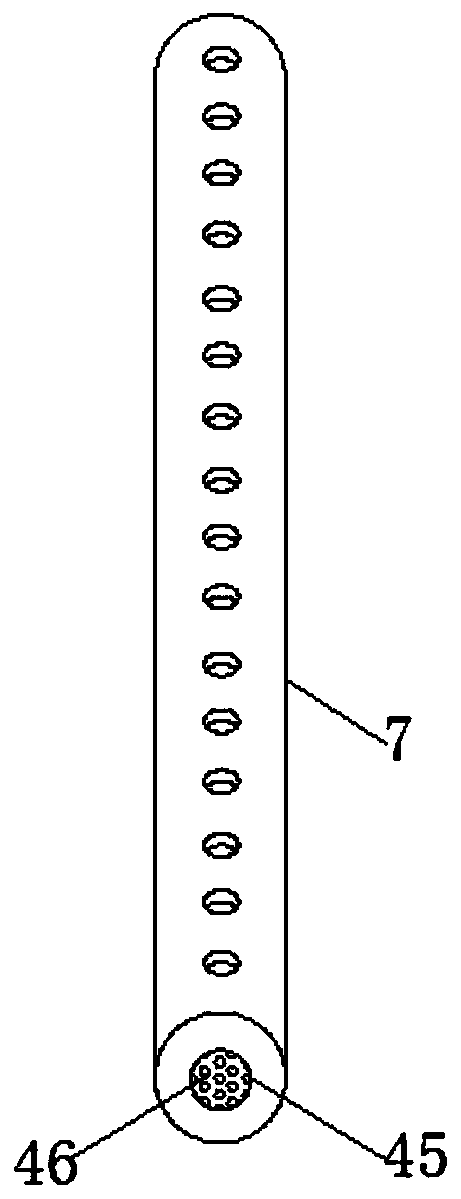

Tea leaf cutting and winnowing integrated apparatus

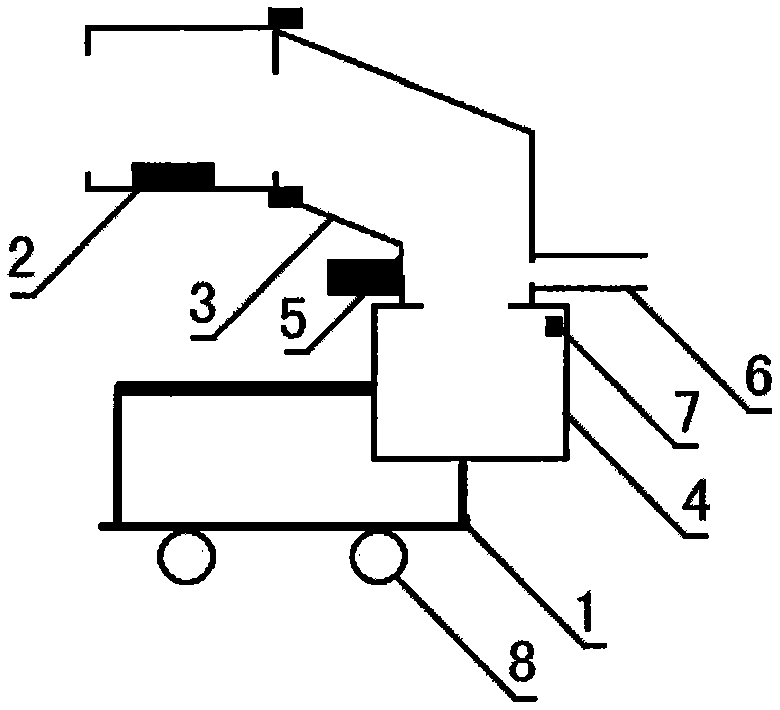

InactiveCN105075518AImprove winnowing effectImprove picking efficiencyGas current separationPicking devicesEngineeringTea leaf

A tea leaf cutting and winnowing integrated apparatus comprises a movable frame [1]. The front end of the frame is a tea leaf cutting device [2]. The lower section of the cutting device is provided with an air duct [3]. The tail end of the air duct [3] is provided with a collection bag [4]. The air duct is provided with a blower motor [5]. When green leaves are picked and enter the air duct, the tea leaves with different lengths and impurities are separated according to weight, the tea leaves falling into the collection bag [4] and some impurities being discharged on site through a waste pipe [6]. The cutting device is arranged in a movable manner and is suitable for cutting of green leaves at different angles. The collection bag [4] is provided with a sensing device [7], so that when the bag is full of tea leaves, a prompt message is given. The green leaves are cut and winnowed at the same time, so that the winnowing effect is effectively improved and the picking efficiency is increased.

Owner:XINCHANG DONGMING BAOYU MACHINERY FACTORY

Vortex cross flow grading type solid particle separating device

The invention relates to the technical field of particle separation and discloses a vortex cross flow grading type solid particle separating device comprising a shell. An inner cavity is arranged in the shell. The upper portion of the inner cavity is provided with a feed opening. A conical scattering assembly, an air supply channel and an air guide channel are arranged in the inner cavity, whereinthe small end of the conical scattering assembly is used for receiving materials flowing in from the feed opening, an interval remains between the circumferential side of the conical scattering assembly and the inner wall of the inner cavity to form a flow splitting channel, the air supply channel is used for providing the wind flowing in the direction opposite to the flowing direction of the materials in the flow splitting channel, the air guide channel runs through the circumferential side of the conical scattering assembly. The vortex cross flow grading type solid particle separating device has the technical effects that supplied air of the air supply channel drives powder and part of fine particles to float upward to separate from the material flow; the supplied air of the air supplychannel can also make contact with the material again through the air guide channel, the number of times of penetrating the particle material layer of the air flow is increased, the contact time between the air flow and the particle material layer is prolonged, and therefore the winnowing effect is improved.

Owner:四川衡工智造科技有限公司

Tea winnowing machine

InactiveCN106040584ALarge contact surfaceImprove winnowing effectGas current separationTea leafEngineering

The invention discloses a tea winnowing machine. The tea winnowing machine comprises a winnowing tank and a fan, wherein the winnowing tank is a transversely horizontally placed cuboid tank; supporting feet are mounted at the bottom of the winnowing tank; an air inlet is formed in the upper part of a right plate of the winnowing tank; a feed hopper is mounted on a feed inlet in the right side of a top plate of the winnowing tank; a plurality of continuous longitudinal material collecting hoppers are arranged on a bottom plate of the winnowing tank; hopper openings of the material collecting hoppers are rectangular; the fan is an induced draught fan; the fan is mounted and fixed to an air draft opening in a left plate of the winnowing tank; a longitudinal slot is formed between every two adjacent material collecting hoppers; rubber layers are arranged on the side walls in the slots; the length of the slots is the same as the length of the material collecting hoppers; baffle plates are inserted from the slots into the winnowing tank from bottom to up; the rubber layers clamp the baffle plates; and the baffle plates can be pulled up and down between the rubber layers. According to the tea winnowing machine, the structure is simple, the operation is convenient, the manufacturing cost is low, the winnowing effect of the tea winnowing machine can be remarkably improved, and the quality of tea of all winnowing levels is effectively improved.

Owner:池州市华茂茶业有限公司

Seed screening device for agricultural production

InactiveCN111185382AImprove filtering effectGood dispersionGas current separationSeed and root treatmentAgricultural scienceAgricultural engineering

The invention belongs to the technical field of agricultural production, and particularly relates to a seed screening device for agricultural production. For solving the problem of poor seed screeningeffect in the prior art, the seed screening device comprises a box body, wherein a feeding hopper is fixed to one side of the outer wall of the top of the box body, inclined blowing pipes are fixed to the two ends of the box body and the outer walls of the two sides of the box body, the ends, close to the interior of the box body, of the blowing pipes incline upwards, blowing fans are fixed to the inner walls of the blowing pipes, exhaust pipes are fixed to the positions, located at the top of the blowing pipes, of the two ends of the box body and the outer walls of the two sides of the box body, and exhaust fans are fixed to the inner walls of the exhaust pipes. According to the seed screening device, dust in seeds is discharged from the exhaust pipes through the wind direction cooperation operation between the blowing pipes and the exhaust pipes, the rest seeds fall into an auxiliary box containing salt water, the seeds with insufficient plumpness float on the water surface and areled out from a drainage pipe, and therefore winnowing and water separation operation is completed in the box body simultaneously; the seed screening effect of the device is improved.

Owner:杨理建

Husked rice separating and screening device for rice processing

InactiveCN111804588AControl flow rateAdjustable sizeGas current separationDispersed particle filtrationAgricultural scienceAgricultural engineering

The invention discloses a husked rice separating and screening device for rice processing. The husked rice separating and screening device comprises a winnowing box, wherein a discharging hopper is fixedly arranged at the top end of the winnowing box; a dust removal box is fixedly connected to one side of the winnowing box; a mounting box is fixedly connected to one side, far away from the dust removal box, of the winnowing box; a first air blower is fixedly arranged in the mounting box; a speed adjusting box is fixedly connected to one side of an opening in the bottom end of the discharging hopper; a first rotating motor is fixedly arranged on the speed adjusting box; and a threaded rod which is horizontally arranged is rotationally arranged in the speed adjusting box. The husked rice separating and screening device is ingenious in structure and convenient to use, the effect of rapidly winnowing the rice can be achieved, the winnowing efficiency is high, the effect is good, rice husksand dust are sucked into the dust removal box, dust removal is carried out through water mist sprayed out by rotating a container, a large amount of dust cannot be generated in the whole winnowing process, the situation that workers inhale dust is effectively prevented, and the health of the workers can be effectively protected.

Owner:ANHUI FUNING RICE IND CO LTD

Rice winnowing machine

InactiveCN107855275AEasy to dryImprove winnowing effectGas current separationDrying gas arrangementsAir velocityHusk

The invention discloses a rice winnowing machine which comprises a case, an exhausting blade, a rotary shaft and drying machines, wherein a feeding hole is formed in the top of the case; husk outletsare formed in the upper side of the case, are V-shaped and are mounted at the top of the rotary shaft; a rice outlet is formed in the lower side of the case; the rotary shaft is hollow and communicates with the exhausting blade; the drying machines are arranged on two sides of the interior of the case; a spiral rotating vane is mounted on the rotary shaft; and turntables are arranged at two ends of the spiral rotating vane on the rotary shaft. According to the rice winnowing machine, the drying machines are arranged in the case to rapidly dry damp unhusked rice for winnowing; and a V-shaped rack is designed to have high air velocity , so that rice husks can be blown into the husk outlets in two sides of the case, and the winnowing efficiency is improved.

Owner:天长市天鑫粮油贸易有限责任公司

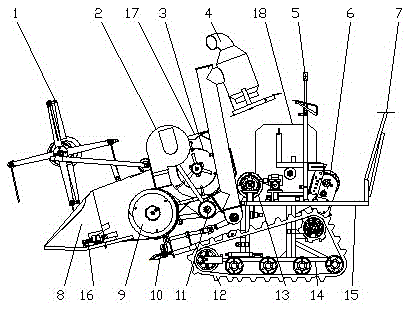

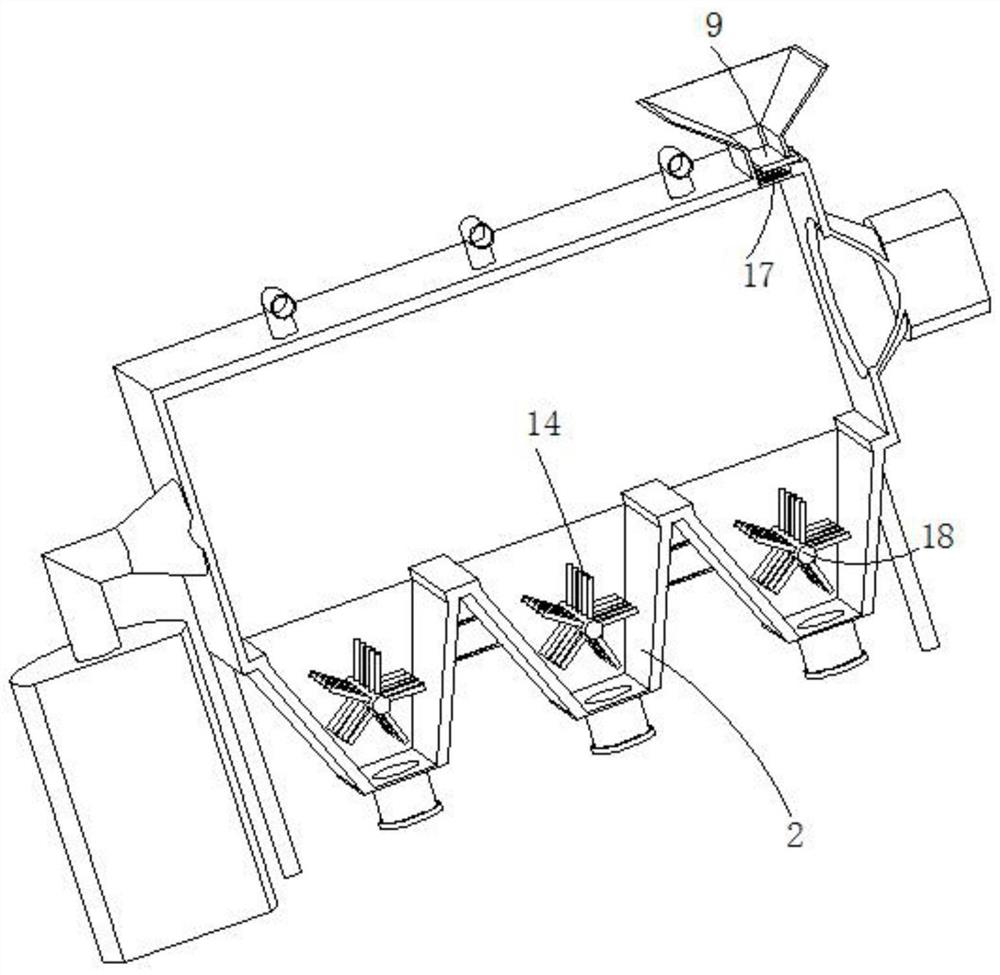

Crawler type small-sized combined harvester

InactiveCN105557185AReasonable structureReasonable arrangementMowersThreshersAgricultural engineeringAir separation

The invention provides a crawler type small-sized combined harvester and relates to a combined harvester in agricultural machinery. The crawler type small-sized combined harvester adopts a crawler to walk; a cutting table is arranged at the front end of a big frame; a walking wheel carrier is arranged at the lower part of the big frame; an operating table, a speed changing box, a clutch and an engine are arranged on the big frame; a seat is arranged at the rear part of the big frame; the cutting table mainly consists of a grain lifter, a threshing cage, a big stirring cage, a lower cutting knife, a small stirring cage, an upper cutting knife, a fan and a lifting cage. The crawler type small-sized combined harvester is characterized in that the inclination angle of a sine rotating piece on a threshing cage cover of the threshing cage can be adjusted; a rotating piece on a small stirring cage shaft is a combination of the sine rotating piece and an anti-sine rotating piece; the anti-sine rotating piece is positioned at the tail end of the shaft. The crawler type small-sized combined harvester is more reasonable in whole machine structure and arrangement, small and compact in whole machine structure, convenient to use and wide in adaptability, the negative pressure air separation effect of an air suction fan is good, residues are discharged downwards, and the crawler adopts a triangular layout, so that the effect of the harvester in a rotten field is obviously improved, therefore, the crawler type small-sized combined harvester has a promotional value.

Owner:重庆翰浦机电设备制造有限公司

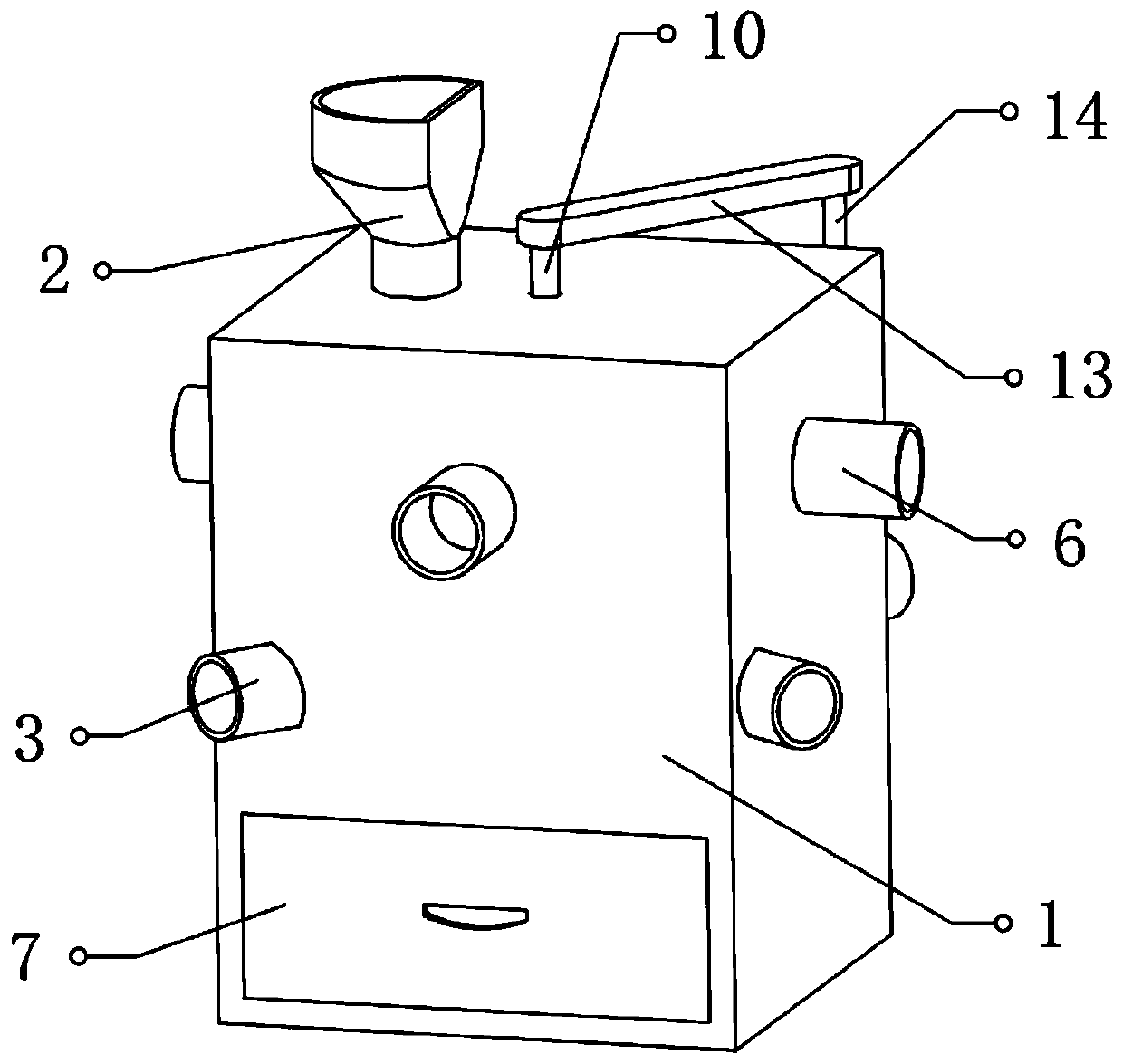

Screening-washing function integrated equipment for processing traditional Chinese medicines

InactiveCN111672757AGood dispersionEasy to observeGas current separationCleaning using liquidsProcess engineeringIndustrial engineering

The invention discloses screening-washing function integrated equipment for processing traditional Chinese medicines in the technical field of traditional Chinese medicine processing washing. The screening-washing function integrated equipment for processing the traditional Chinese medicines comprises a winnowing box; the winnowing box is provided with a material feeding hopper; the material feeding hopper is provided with a stopping plate; the material feeding hopper is provided with a grid; the winnowing box is connected with a fan; the winnowing box is provided with a gas outlet pipe; the gas outlet pipe is provided with a dust collection box; the winnowing box is provided with washing hoppers; the winnowing box is provided with water injection pipes; the washing hoppers are provided with bearings; the bearings are provided with stirring shafts; the stirring shafts are provided with stirring rods; the stirring shafts are provided with belt wheels; a belt is movably connected to thebelt wheels; the external side walls of one group of the belt wheels are fixedly connected with an output end of a motor; transparent glass windows are fixedly connected to the interiors of through holes in the rear side walls of the washing hoppers; and material outlet pipes are fixedly connected to the bottoms of the washing hoppers. According to the screening-washing function integrated equipment for processing the traditional Chinese medicines, the traditional Chinese medicines dropping from the material feeding hopper are winnowed by using dynamic air generated by the fan; and the screened traditional Chinese medicines fall into the different washing hoppers so that the device can winnow the traditional Chinese medicines before the traditional Chinese medicines are washed.

Owner:王芙蓉

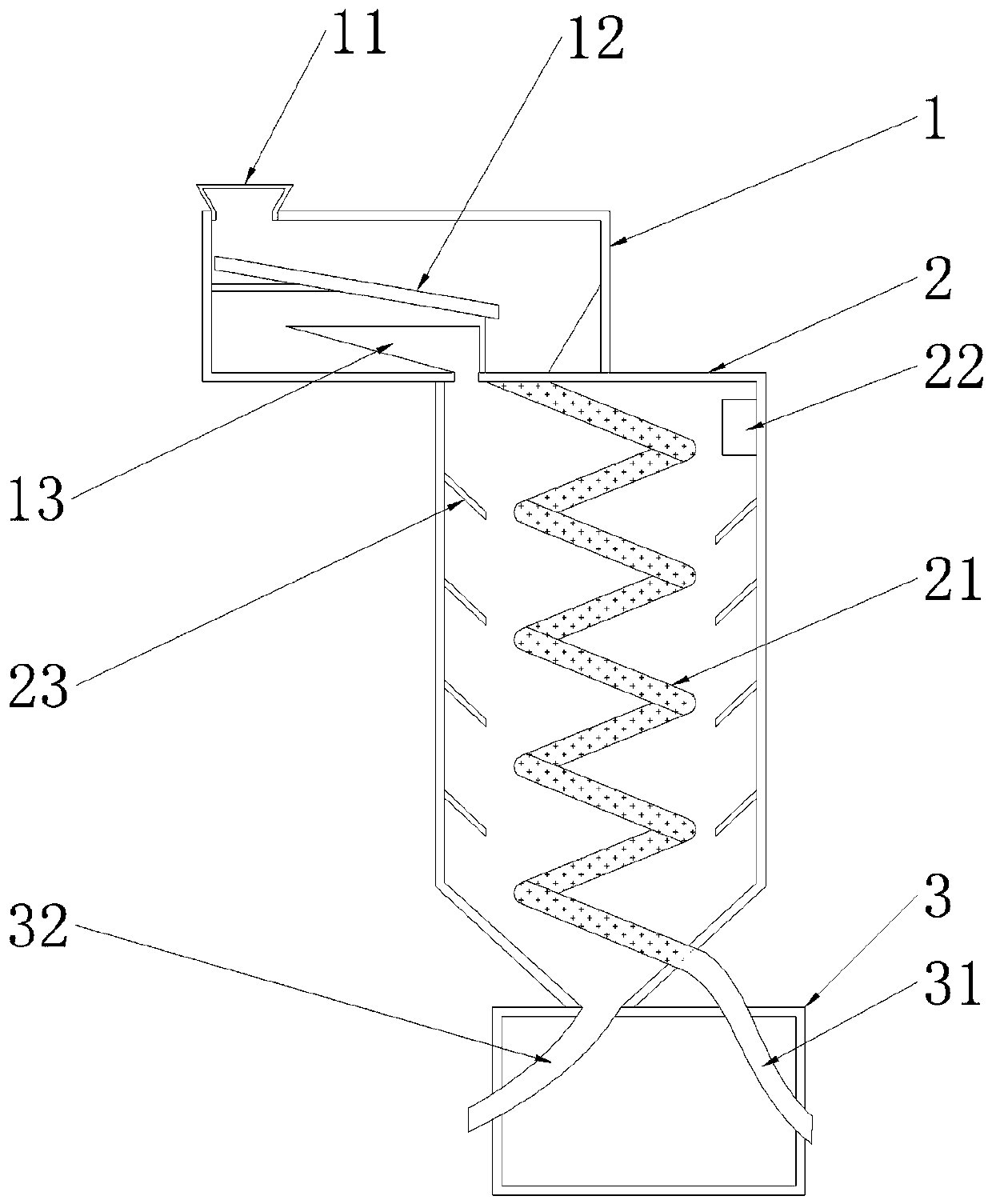

Finish machining system of rice

InactiveCN107670750AThere will be no clogging of the screen holesImprove sorting efficiencyGas current separationGrain treatmentsBroken riceAgricultural engineering

The invention discloses a finish machining system of rice. The finish machining system is composed of a screening device, a rubber roller husking device, a husked rice separation device, a rice milling device, a polishing device, a packing machine and a storage bin, wherein the screening device, the rubber roller husking device, the husked rice separation device, the rice milling device, the polishing device, the packing machine and the storage bin are connected in sequence, a sorting device which is respectively connected with the polishing device and the packing machine is arranged between the polishing device and the packing machine, the sorting device comprises a feeding chamber, a sorting chamber and a discharging chamber which are connected in sequence from top to bottom, a rice screening tube is spirally arranged in a vertical direction in the sorting chamber, the upper end of the rice screening tube communicates with the feeding chamber, the lower end of the rice screening tubecommunicates with the discharging chamber, a plurality of screening holes which are used for screening broken rice are formed in the rice screening tube, and an air regulator is arranged in the sorting chamber. According to the finish machining system, rice can be effectively sorted after being polished, and complete rice is separated from the broken rice, so that the uniformity of finished riceis increased, and the broken rice can be conveniently recycled.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

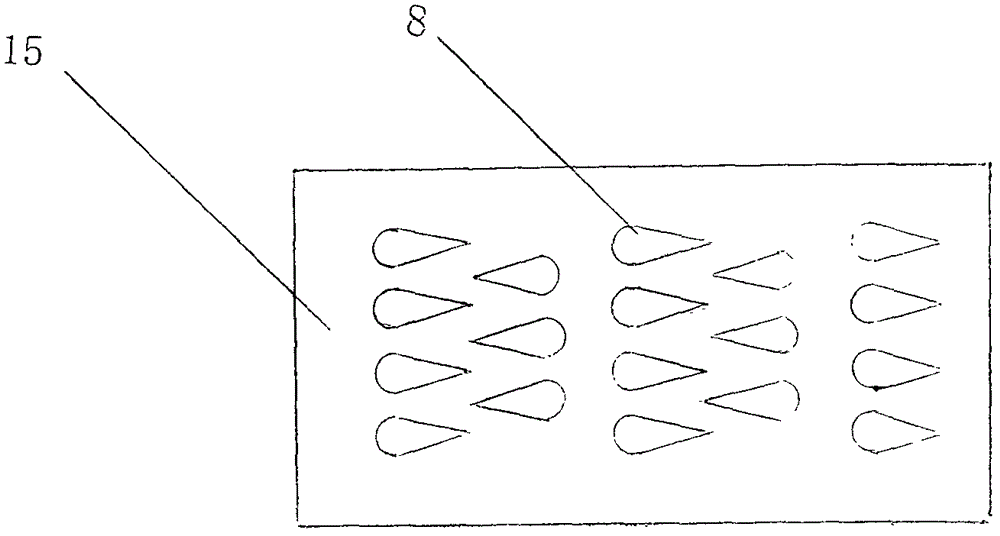

Sorting system of brand watermelon seeds

InactiveCN106345695AImproved size sorting accuracyImprove winnowing effectSievingGas current separationVentilation tubeAir volume

The invention discloses a sorting system of brand watermelon seeds, wherein the sieve is hanged at the upper of framework by four derricks, the back of the sieve is connected with the eccentric place of motor spindle rotary table by connecting rod, inside the sieve, there have the first layer screen and the second layer screen, at the lower of the framework, there has ventilation pipe, the first drawer and the second drawer are equipped under the ventilation pipe, the ventilation pipe is rectangular and provided with hopper, above the hopper, the rectangular closed tube is connected with the middle and lower chute, a draught fan is provided before the ventilation pipe, the mesh of the second layer screen are all the shape of watermelon seeds and the screen are all lined in the same horizontal mode and opposite tandem mode, between the ventilation tube and draught fan, there is the wind speed uniform device. As the mesh of screen uses the watermelon shape, the device could improve the sorting accuracy of the watermelon seeds size, and the wind speed uniform device could increase the aspiration effect, separate the full watermelon seeds and non-full watermelon seeds and adjust the speed of motor to make the air volume and wind pressure changing at the same time, as well as finding the proper wind to separate easily.

Owner:胡增德

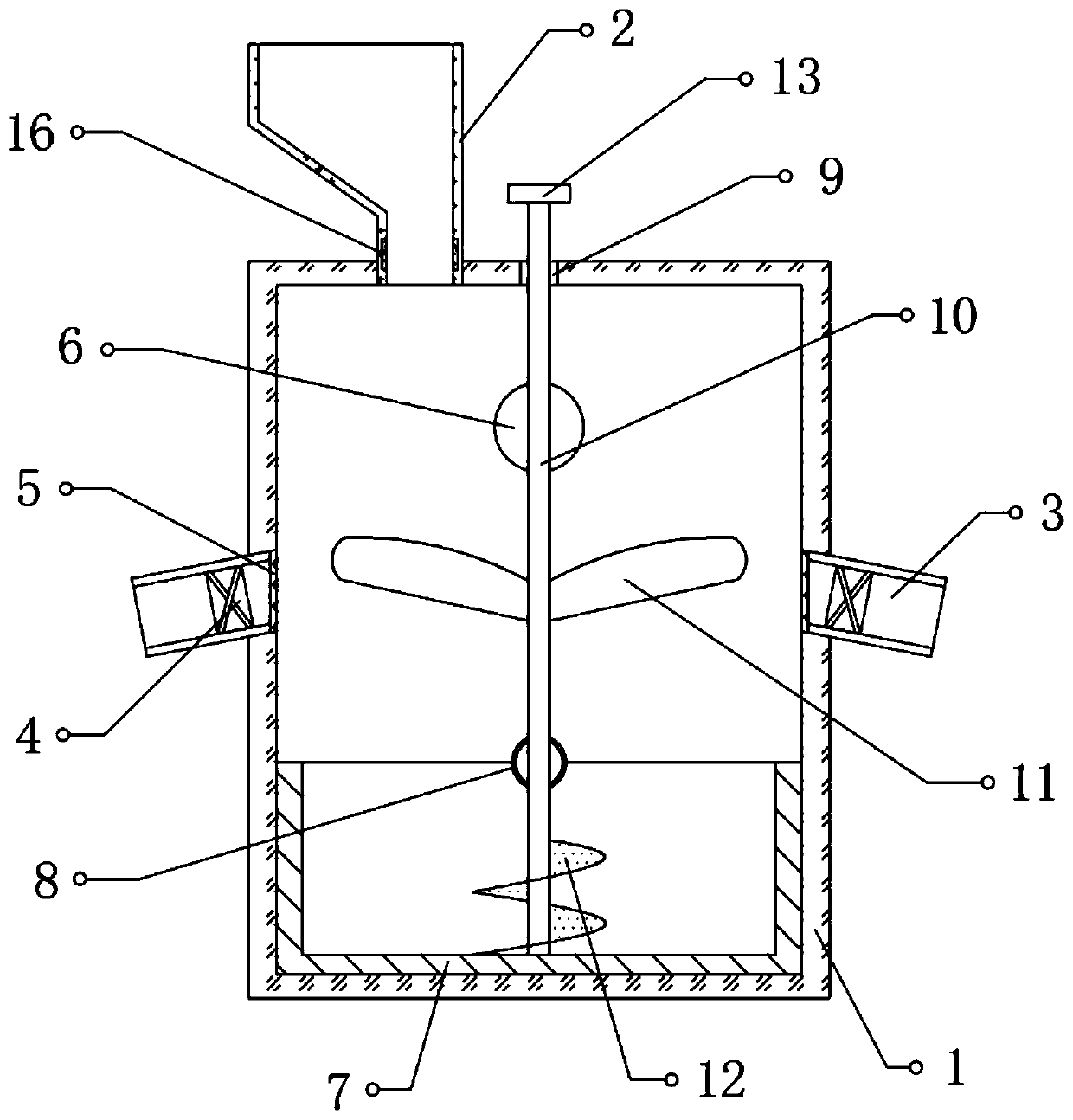

Tea leaf winnowing machine

InactiveCN107413647AImprove winnowing effectKeep healthyGas current separationAgricultural engineering

The invention discloses a tea winnowing machine, which comprises a frame body, a frame leg, a material inlet, a screening device, a blower, a main air inlet, an auxiliary air inlet, an air outlet, a collecting hopper, a distribution hopper, a recycling hopper and a dust collecting cloth bag , the frame legs are fixedly connected to the four corners of the lower surface of the frame, the inlet is opened on the top of the frame, the screening device is located below the inlet, and the main air inlet , the auxiliary air inlet, the receiving hopper, the distribution hopper and the recovery hopper are all arranged at the bottom of the frame, the main air inlet is located on the left side of the auxiliary air inlet, and the receiving hopper It is arranged between the main air inlet and the auxiliary air inlet. Beneficial effects: the present invention uses the screening device to sieve a large amount of tea leaves, so that the tea leaves are in a relatively uniform state during the winnowing process, thereby enhancing the winnowing effect of the winnowing machine and achieving the purpose of winnowing and grading.

Owner:安徽香草茶业有限公司

Adjustable type grain winnowing device

ActiveCN107952682AGuarantee product qualityImprove winnowing effectGas current separationAgricultural engineeringProduction quality

The invention discloses an adjustable type grain winnowing device and relates to the technical field of grain processing equipment. The adjustable type grain winnowing device comprises a rack; an outer tube is arranged on the top face of the rack; an inner tube is arranged inside the outer tube; a cavity is formed between the outer tube and the inner tube; a plurality of adhesive plates are evenlyand movably inserted in the side face of the outer tube in a penetrating mode; one ends of the adhesive plates abut against the outer surface of the inner tube; the bottom end of the inner tube penetrates through the rack and is connected with a discharging pipe; a plurality of air outlets are arranged on the side face of the inner tube in a matched mode; a wind conveying pipe is arranged insidethe inner tube; a plurality of sets of wind outlet pipes are evenly arranged on the outer surface of the wind conveying pipe; an adjusting mechanism is arranged at the top end of the inner tube; and the top of the adjusting mechanism is connected with a feeding hopper. As the outer tube and the inner tube are cooperatively connected and the adjusting mechanism is arranged in a matched mode, the winnowing effect is effectively improved, the production quality of grains is ensured, and the use cost of products is also lowered.

Owner:JIESHOU XINLONG GRAIN & OIL MACHINING

Cleaning device for tea winnowing machine

InactiveCN108927329AImprove winnowing effectImprove cleaning abilityGas current separationPre-extraction tea treatmentDrive motorEngineering

The invention discloses a cleaning device for a tea winnowing machine. The cleaning device for the tea winnowing machine comprises a winnowing cylinder body, an air blower, a wind input pipe, a feeding device, a first discharging port, a second discharging port, a third discharging port, a dust discharging pipe, a shock reduction device and a dust collection device. A first mounting plate is fixedly connected to the bottom of the right side of the winnowing cylinder body. The shock reduction device is fixedly connected to the bottom of the right side of the first mounting plate. A first mounting base is arranged at the top of the first mounting plate. The air blower is mounted on the first mounting base. The wind outlet of the air blower is connected with the wind input pipe. The other endof the winnowing cylinder body is in communication with the dust discharging pipe. The bottom end of the dust discharging pipe is fixedly connected with the dust collection device. The feeding deviceis arranged on the portion, close to one end of the air blower, of the winnowing cylinder body. The feeding device comprises a feeding hopper and a tea-loosening mechanism. A second mounting plate isfixedly connected to the upper end of the right side of the winnowing cylinder body. The tea-loosening mechanism comprises a loosening cavity, a driving motor, a stirring shaft, a coupling and stirring blades. A second mounting base is mounted at the top of the second mounting plate. The driving motor is mounted on the second mounting base. The driving motor is connected with the stirring shaft through the coupling.

Owner:芜湖市春满壶茶业有限公司

Hulling and separating all-in-one machine for rice processing

InactiveCN112934307AEasy to processImprove processing efficiencyGrain huskingGrain polishingMolecular sieveAgricultural engineering

The invention discloses a hulling and separating all-in-one machine for rice processing. The machine comprises a hulling box, a feeding hopper, a hulling rubber roller, a material guiding inclined plate, a material guiding hopper, a winnowing hopper, an ascending fan impeller, a material uniformizing box, a V-shaped material guiding plate, a material uniformizing opening, a canvas soft connector, a uniform feeding opening, a separating box, a rice discharging opening, a brown rice discharging opening, a rice husk discharging opening, an air inlet duct, a dust removing box, air supply fan blades, a drawing frame, a molecular sieve honeycomb plate, a fixed support and an angle adjusting rotary knob. According to the invention, a traditional split type structure is replaced with an integrated structure, and the hulling process and the separating process are integrated into one process, so that the processing flow of rice is simplified, the conveying frequency of materials is reduced, the manpower is saved, the falling risk of the materials is reduced, and the processing efficiency of the rice is improved; and a vortex winnowing mode is used for replacing a traditional direct-current winnowing mode, so that the winnowing strength of the all-in-one machine is enhanced, the residual quantity of rice hulls in brown rice is reduced, and the winnowing effect of the all-in-one machine is improved.

Owner:江西华汾粮油实业有限公司

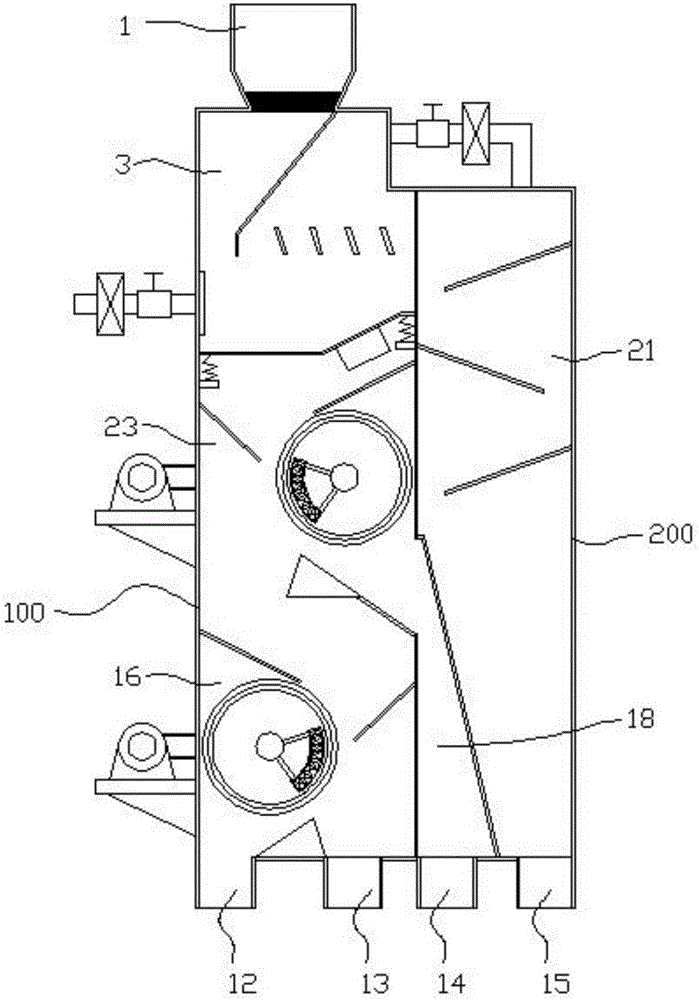

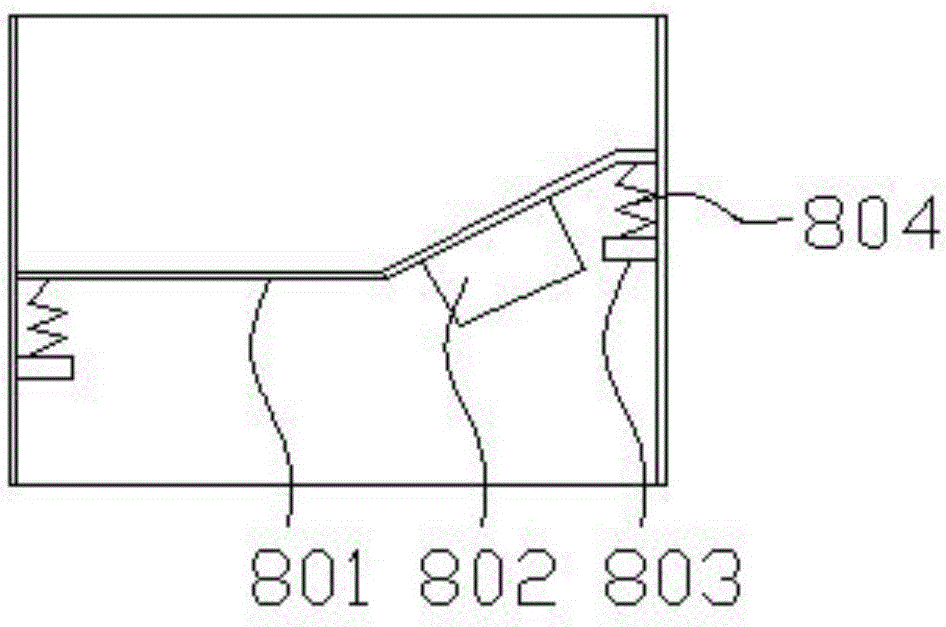

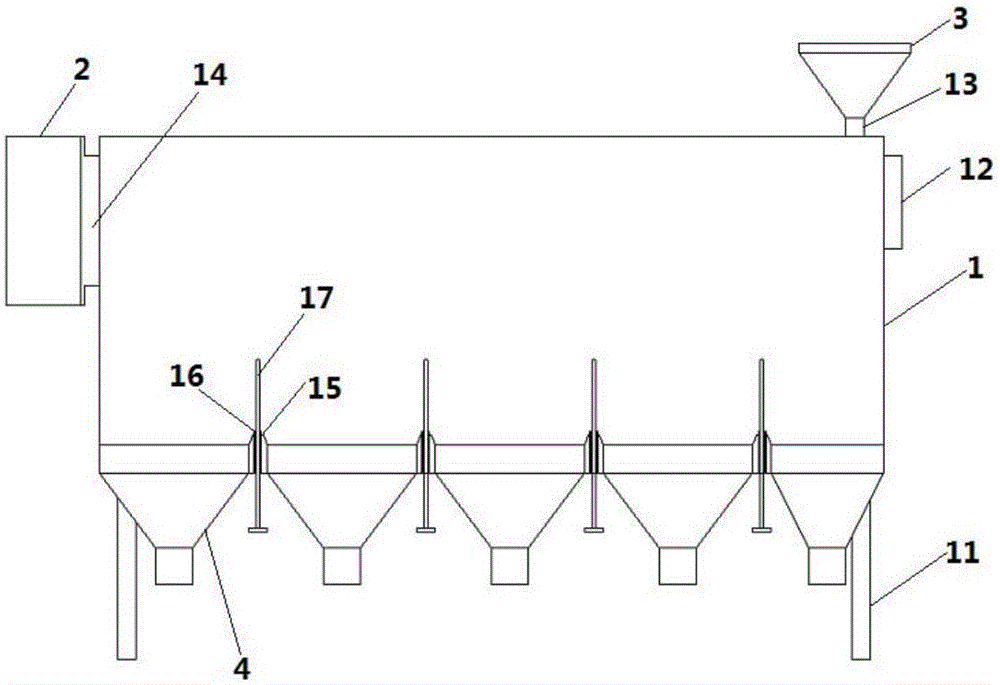

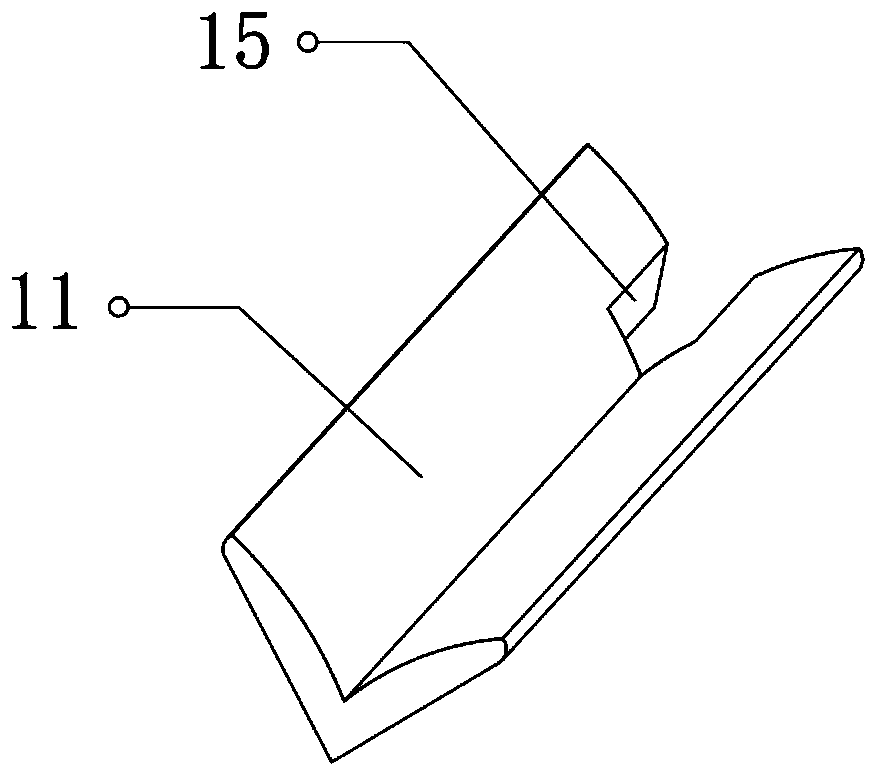

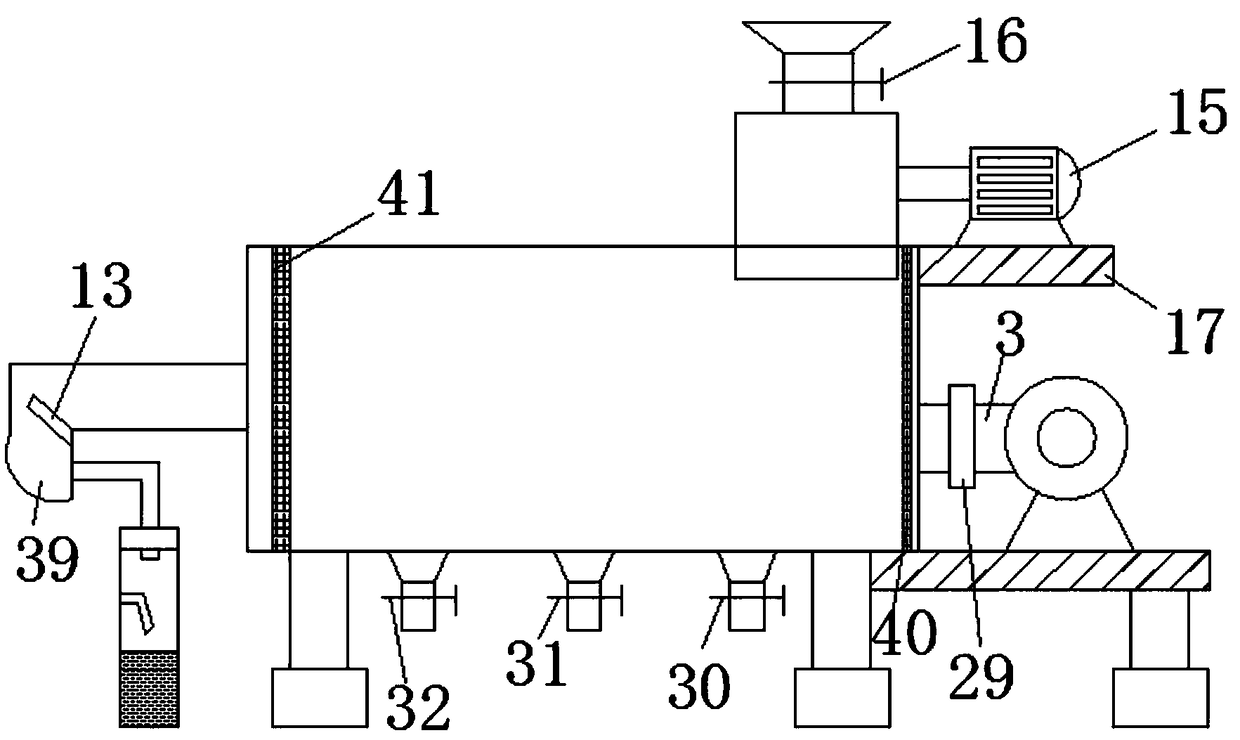

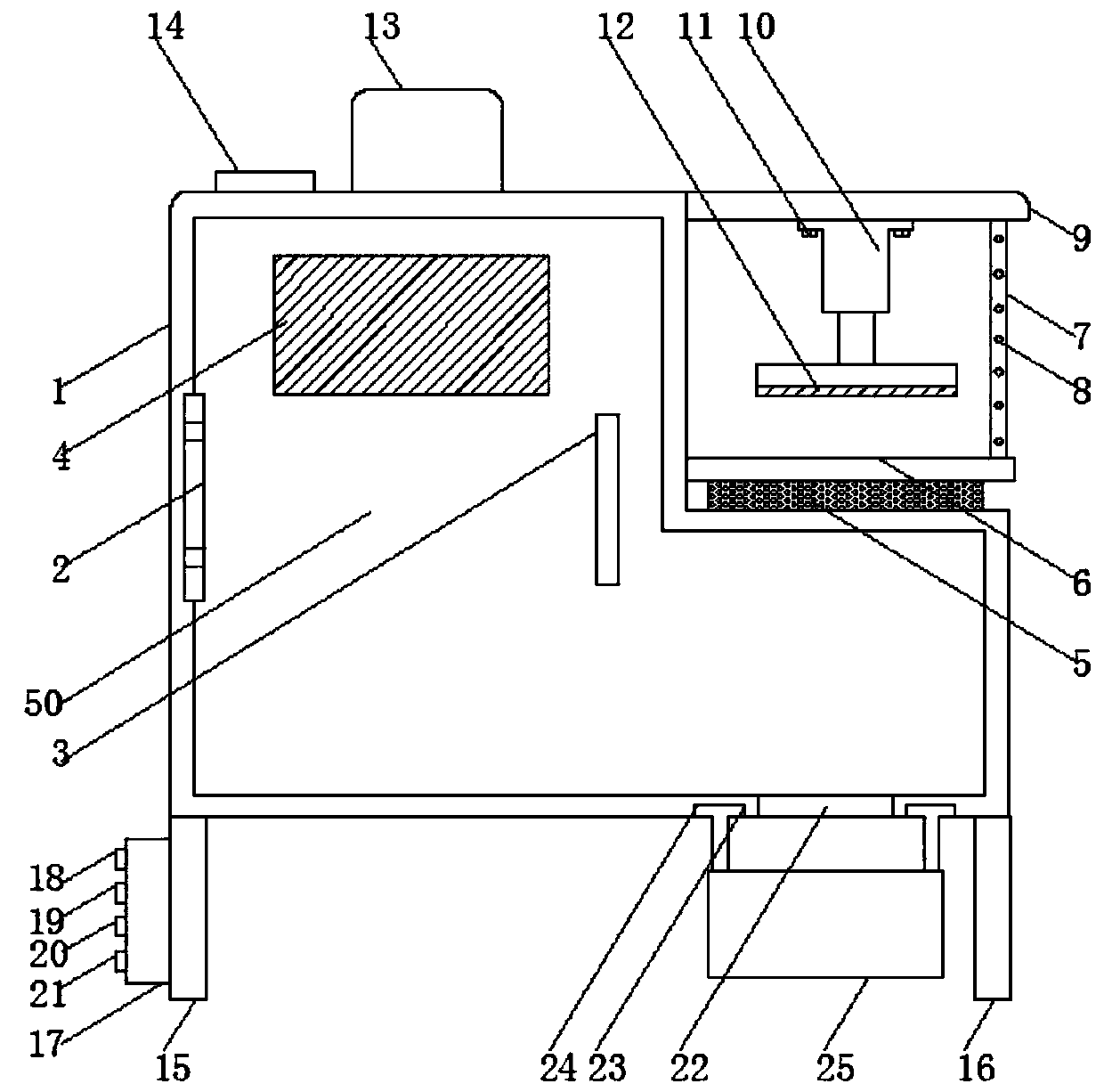

Anti-blocking grain baffling type screening machine

PendingCN107442432AReduce pollutionImprove winnowing effectGas current separationHeat conductingEngineering

The invention discloses an anti-blocking type grain baffle screening machine, which comprises a support box and an overturn box fixed on the support box and communicated with the support box. There is a connecting channel between the boxes. The bottom of the flip box is equipped with a material guide slant plate with a lower left and a higher right. There are two partition plates arranged in parallel at the bottom of the support box. The partition plate separates the support box into three storage boxes. In the material area, the overturning box is a rectangular box, and a heat-conducting oil jacket is installed on the side wall of the overturning box, and the heat-conducting oil jacket is connected with a heat-conducting oil furnace through a circulating pipeline; The feeder is blocked; the left and right inner walls of the turning box are crossed with several baffle and turning plates; the upper right side of the turning box is provided with an exhaust pipe, which is connected to the air injection pipe on the upper left side of the support box through the air hose; the air hose Pass through the exhaust fan, dust box and drying box on the right side of the turning box from top to bottom.

Owner:郑素华

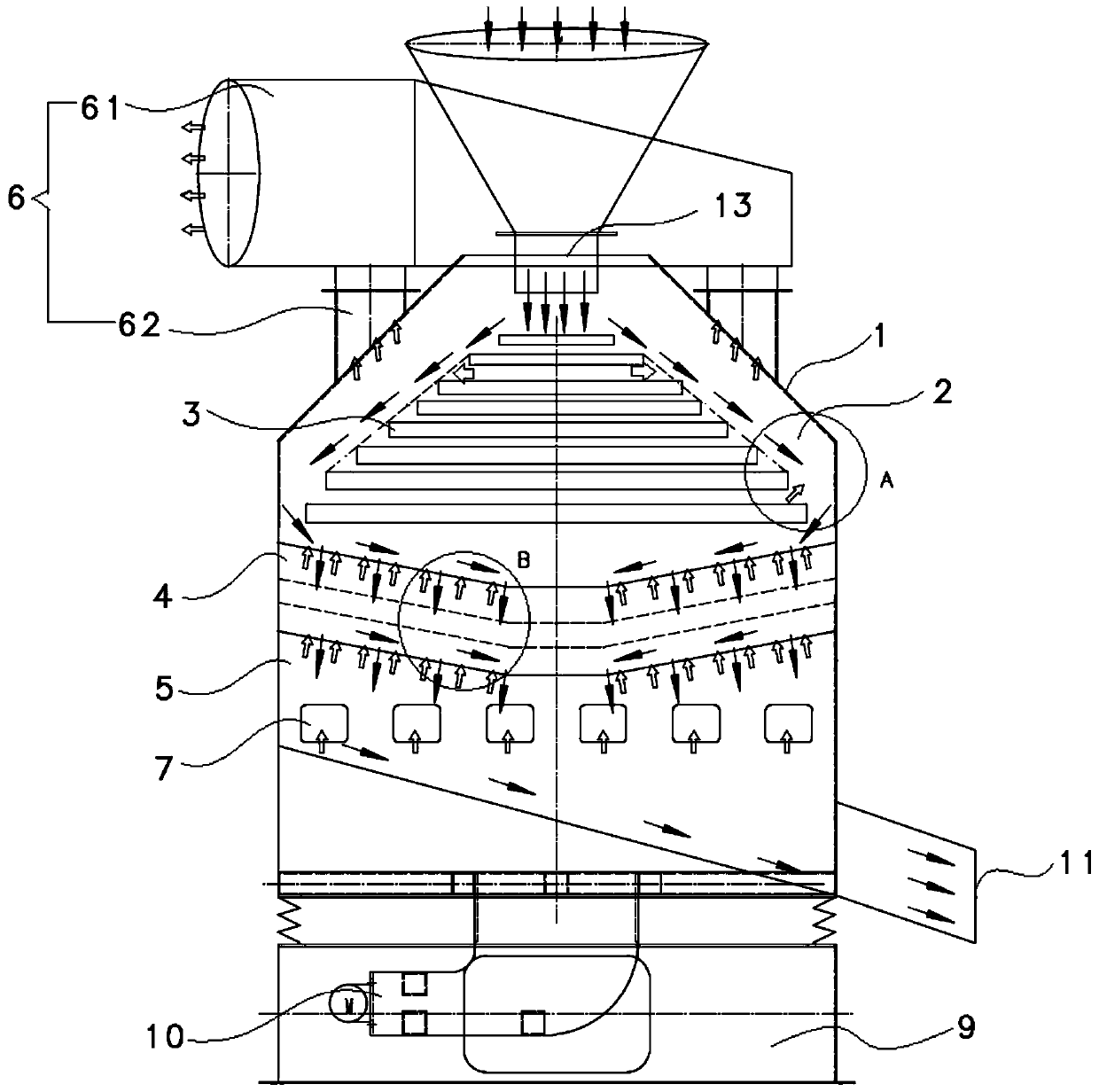

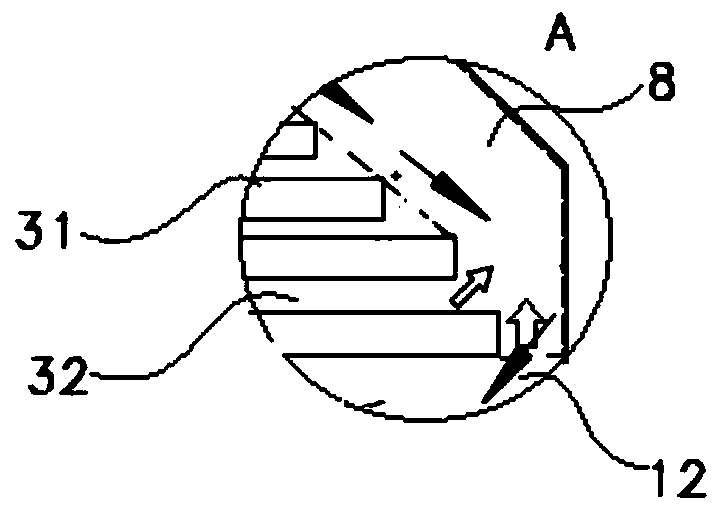

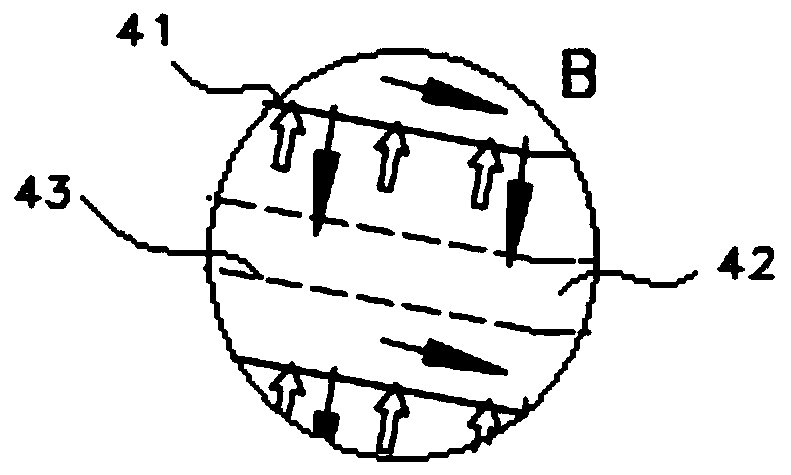

Tea winnower

The invention discloses a tea winnower. The tea winnower comprises a cylindrical machine body, a feed device, a discharge device and a controller. The feed device is arranged above the machine body. The discharge device is arranged below the machine body. The controller is arranged on the machine body. A channel A and a channel B which are in the axial direction of the machine body are arranged in the machine body. The channel A and the channel B are each provided with a wind speed inductor, and the wind speed inductors are used for detecting the wind speed in the channel A and the wind speed in the channel B. The wind speed inductors are connected with the controller. One end of the channel A is provided with a fan A. The other end of the channel A is provided with a wind channel conveying tea to the channel B. One end of the channel B is provided with a fan B. The other end of the channel B is connected with the discharge device. The fan A and the fan B are located at the left end and the right end of the machine body respectively, and the fan A and the fan B are opposite in direction. The fan A and the fan B are connected with the controller. The two channels are adopted for winnowing, so that the winnowing effect is improved, and impurities are removed more completely. In addition, the wind speed inductors and the controller are matched with each other, so that not only is the stability of the wind speeds ensured, but also the wind speeds can be adjusted and controlled, and accordingly the precision of winnowing is improved.

Owner:DONGZHI MAKENG YUANKOU TEA IND

Sound insulation cotton waste hammer type crushing and winnowing integrated machine

InactiveCN110202718APractical to useLow costPlastic recyclingMechanical material recoveryPulp and paper industryFan blade

The invention discloses a sound insulation cotton waste hammer type crushing and winnowing integrated machine. The integrated machine comprises a device box body, a motor protective cover is arrangedon the left side of the top of the device box body, a motor is arranged at the top end in the motor protective cover, and a motor shaft is connected to the bottom of the motor. The bottom of the motorshaft penetrates through the device box body and is connected with a first rotating rod, and crushing blades are welded to the tops of the left side and the right side of the first rotating rod. Thebottom of the first rotating rod penetrates through a first fixing plate and is fixedly connected with a first bevel gear. Through the first bevel gear on the first rotating rod, a second bevel gear on a second rotating rod and fan blades, when the first rotating rod drives the crushing blades to crush sound insulation cotton waste, the first bevel gear is used for driving the second rotating rodto rotate, and the crushed sound insulation cotton waste is subjected to winnowing by using the fan blades, so that a plurality of driving devices are omitted, and the cost is reduced.

Owner:YANGZHOU CHUANGQUN NETWORK TECH CO LTD

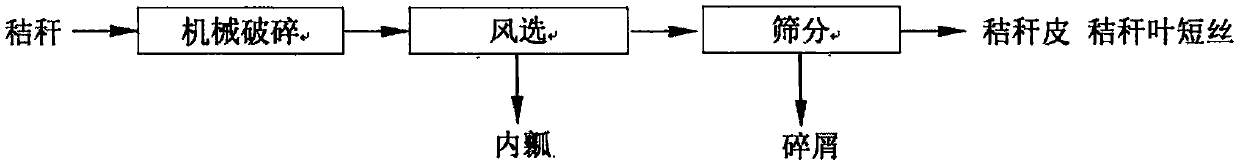

Peel-pulp separation method of maize straw

InactiveCN110521405AReduce processing lossIncrease profitGas current separationCuttersBiologyCorn stover

The invention relates to a peel-pulp separation method of maize straw. The method comprises the following steps that step 1, the maize straw is mechanically crushed, so that straw peels, straw leavesand straw pulp are crushed and separated from one other; step 2, winnowing is performed on the straw peels, straw leaves and straw pulp which are obtained in step 1 to separate the straw pulp from thestraw leaves and the straw peels, and the straw pulp is collected; step 3, screening is conducted through a sieve, and the straw peels and the straw leaves are collected.

Owner:刘丰恺

Coarse filtration system for rice fine processing

InactiveCN107670988AImprove winnowing effectAchieve separationSievingGas current separationFiltrationEngineering

The invention discloses a coarse filtration system for rice fine processing in the technical field of grain processing. The coarse filtration system comprises a feeding bin, a screening bin and a discharging bin which are sequentially connected from top to bottom, wherein a first winnowing chamber and a second winnowing chamber which are arranged side by side in a left-and-right mode and communicate with each other are arranged in the screening chamber; two sets of roller winnowing mechanisms which are spaced and are aligned vertically are arranged in the first winnowing chamber; each roller winnowing mechanism comprises two left-and-right parallel rollers which are rotatably connected with the first winnowing chamber and driven by a motor; a plurality of first fans annularly arranged arearranged in each roller; a plurality of ventilation holes are formed in each roller; second fans for horizontally blowing air are arranged above the rollers; two third fans are arranged in the secondwinnowing chamber; and a rice discharging chamber and a bran discharging chamber are arranged in the discharging bin. According to the coarse filtration system for rice fine processing, through uniquestructural design, thorough separation of the rice from bran can be realized, and the processing of the rice in the later stage and the collection of the bran can be facilitated.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com