Crawler type small-sized combined harvester

A combine harvester and crawler-type technology, which is applied to the chassis of harvesters, cutters, and agricultural machinery, can solve problems such as unreasonable structure, poor winnowing effect, and difficulty in rotten fields, and achieve the structure and layout of the whole machine Reasonable, enhanced effect, small and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

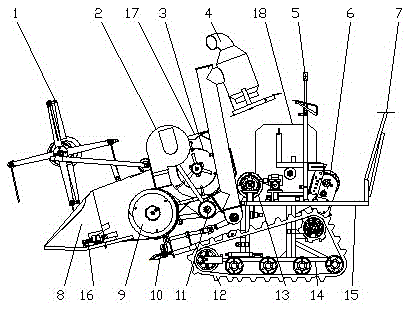

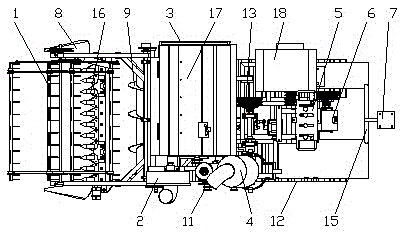

[0021] Such as figure 1 , figure 2 As shown, a crawler-type small combine harvester adopts crawler belts 12 to walk, a header 8 is provided at the front end of the large frame 15, a walking wheel frame 14 is provided at the bottom of the large frame 15, and an operating platform is provided on the large frame 15. 5, gearbox 6, clutch 13, engine 18, are provided with seat 7 at the rear portion of large frame 15, header 8 is mainly made up of grain holding device 1, threshing cage 3, big stirring cage 9, lower cutting knife 10, small Stirring cage 11, upper cutter 16, blower fan 2, lifting cage 4 are formed, the inclination angle of the sinusoidal rotary vane on the threshing cage cover 17 of the threshing cage can be adjusted, and the rotary vane on the shaft of the small stirring cage 11 is a sinusoidal rotary vane and a reverse A combination of chordal rotors, with an antichord rotor at the end of the shaft. The middle part of the sinusoidal rotary vane on the threshing ca...

Embodiment 2

[0023] Such as figure 1 , figure 2 As shown, a crawler-type small combine harvester adopts crawler belts 12 to walk, a header 8 is provided at the front end of the large frame 15, a walking wheel frame 14 is provided at the bottom of the large frame 15, and an operating platform is provided on the large frame 15. 5, gearbox 6, clutch 13, engine 18, are provided with seat 7 at the rear portion of large frame 15, header 8 is mainly made up of grain holding device 1, threshing cage 3, big stirring cage 9, lower cutting knife 10, small Stirring cage 11, upper cutter 16, blower fan 2, lifting cage 4 are formed, the inclination angle of the sinusoidal rotary vane on the threshing cage cover 17 of the threshing cage can be adjusted, and the rotary vane on the shaft of the small stirring cage 11 is a sinusoidal rotary vane and a reverse A combination of chordal rotors, with an antichord rotor at the end of the shaft. The fan 2 is a suction fan, and the lifting cage 4 is mainly comp...

Embodiment 3

[0025] Such as figure 1 , figure 2 As shown, a crawler-type small combine harvester adopts crawler belts 12 to walk, a header 8 is provided at the front end of the large frame 15, a walking wheel frame 14 is provided at the bottom of the large frame 15, and an operating platform is provided on the large frame 15. 5, gearbox 6, clutch 13, engine 18, are provided with seat 7 at the rear portion of large frame 15, header 8 is mainly made up of grain holding device 1, threshing cage 3, big stirring cage 9, lower cutting knife 10, small Stirring cage 11, upper cutter 16, blower fan 2, lifting cage 4 are formed, the inclination angle of the sinusoidal rotary vane on the threshing cage cover 17 of the threshing cage can be adjusted, and the rotary vane on the shaft of the small stirring cage 11 is a sinusoidal rotary vane and a reverse A combination of chordal rotors, with an antichord rotor at the end of the shaft. The fan 2 is a suction fan, and the lifting cage 4 is mainly comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com