Tea winnowing machine

A winnowing machine, tea technology, applied in the direction of solid separation, separating solids from solids with air flow, chemical instruments and methods, etc., to achieve the effects of convenient operation, low manufacturing cost, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

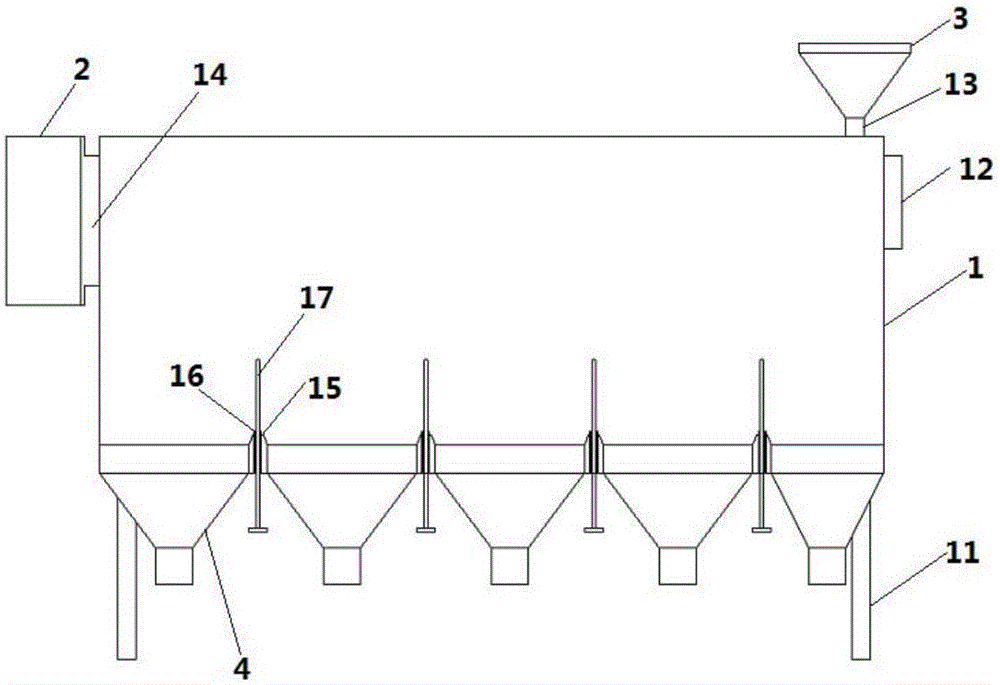

[0016] A tea winnowing machine, comprising winnowing box 1 and blower fan 2, said winnowing box 1 is a cuboid box body placed horizontally and horizontally, supporting feet 11 are installed on the bottom of winnowing box 1, and the right plate of winnowing box 1 The upper part of the air selection box 1 is provided with an air inlet 12, and a feed hopper 3 is installed on the feed opening 13 on the right side of the top plate of the winnowing box 1, and a plurality of continuous vertical receiving hoppers 4 are arranged on the bottom plate of the winnowing box 1. The mouth of the hopper 4 is rectangular, the fan 2 is an induced draft fan, and the fan 2 is installed and fixed on the air outlet 14 on the left plate of the winnowing box 1, and a longitudinal blower is arranged between the two adjacent hoppers 4. The slot 15 is provided with a rubber layer 16 on the side wall in the slot 15, the length of the slot 15 is the same as the length of the receiving hopper 4, and the baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com