Peel-pulp separation method of maize straw

A technology of corn stalks and separation methods, which is applied in the direction of solid separation, chemical instruments and methods, and separation of solids from solids with airflow, etc., which can solve the problems of low utilization rate of straw raw materials, large loss of straw processing, and labor-intensive, etc. Achieve the effects of saving manpower, improving the working environment and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

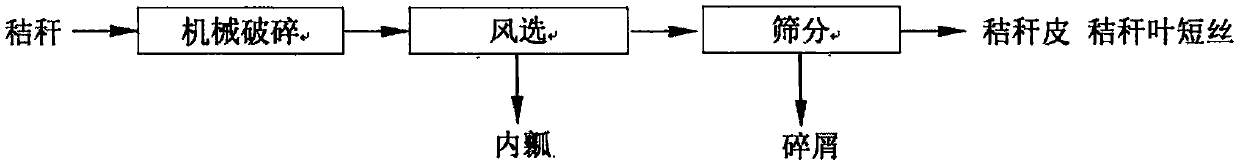

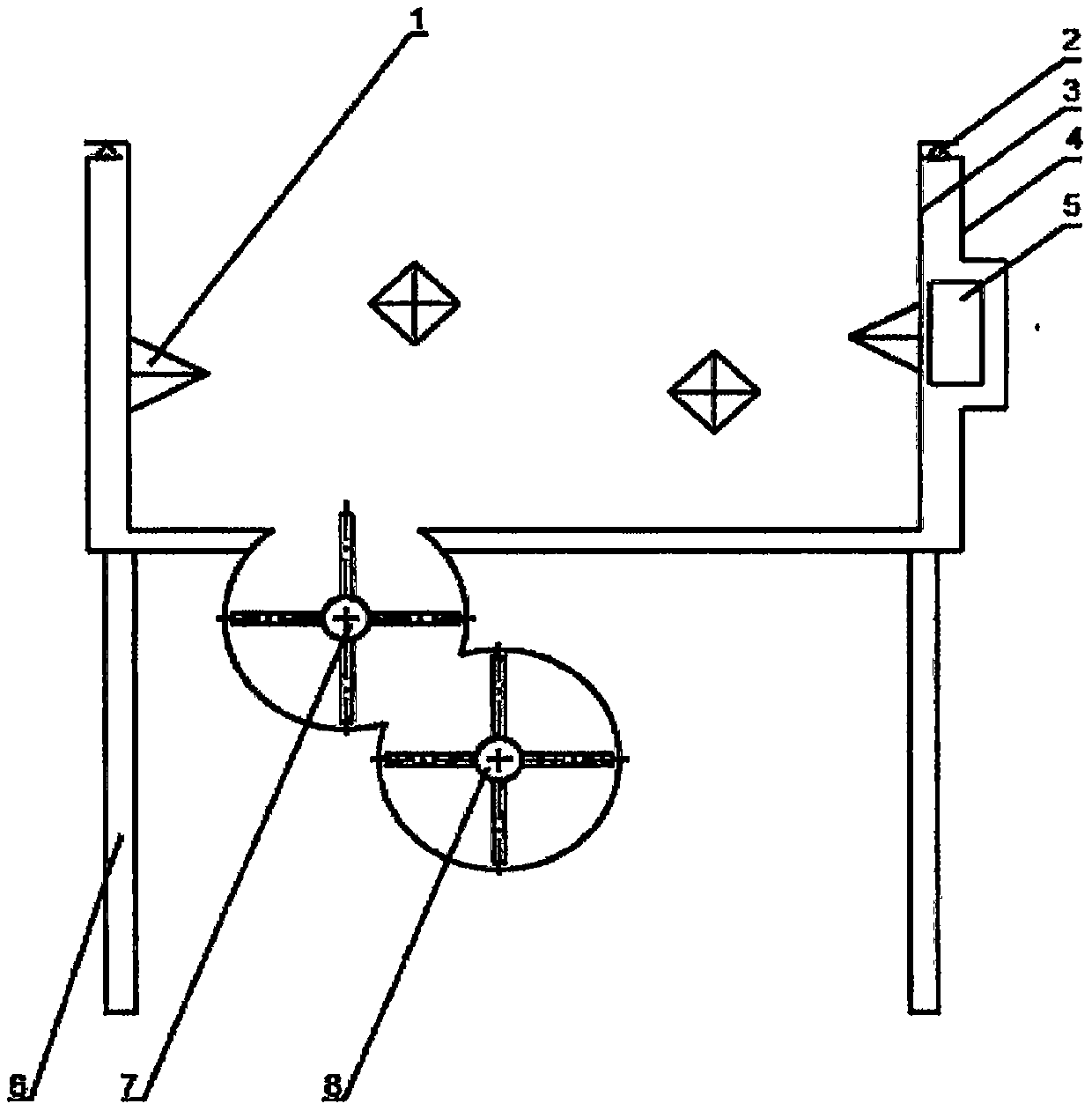

[0024] Such as figure 1 As shown, a method for separating the husk and pulp of corn stalks of the present invention comprises the following steps:

[0025] Step 1: Mechanical crushing. The corn stalks are mechanically crushed, so that the stalk husk, straw leaves, and straw inner flesh are broken and separated from each other.

[0026] Straw husks are crushed into pieces by first cutting with a hob cutter or a twin-shaft crusher, and then rubbing and crushing with a disc crusher or a hammer mill, or directly using a disc crusher or a hammer mill. shape (fragments within 10cm) and debris, of which debris accounted for about 60%, straw leaves were crushed into short filaments and debris, of which short filaments accounted for about 50%, and the inner pulp was crushed into fragments (fragments above 1cm ) and debris, of which debris accounts for about 50%.

[0027] The method of first cutting and then crushing is used to mechanically crush the straw, so that the length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com