Sound insulation cotton waste hammer type crushing and winnowing integrated machine

A technology of hammer crushing and sound insulation cotton, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve problems such as troublesome crushing and air selection, single function, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

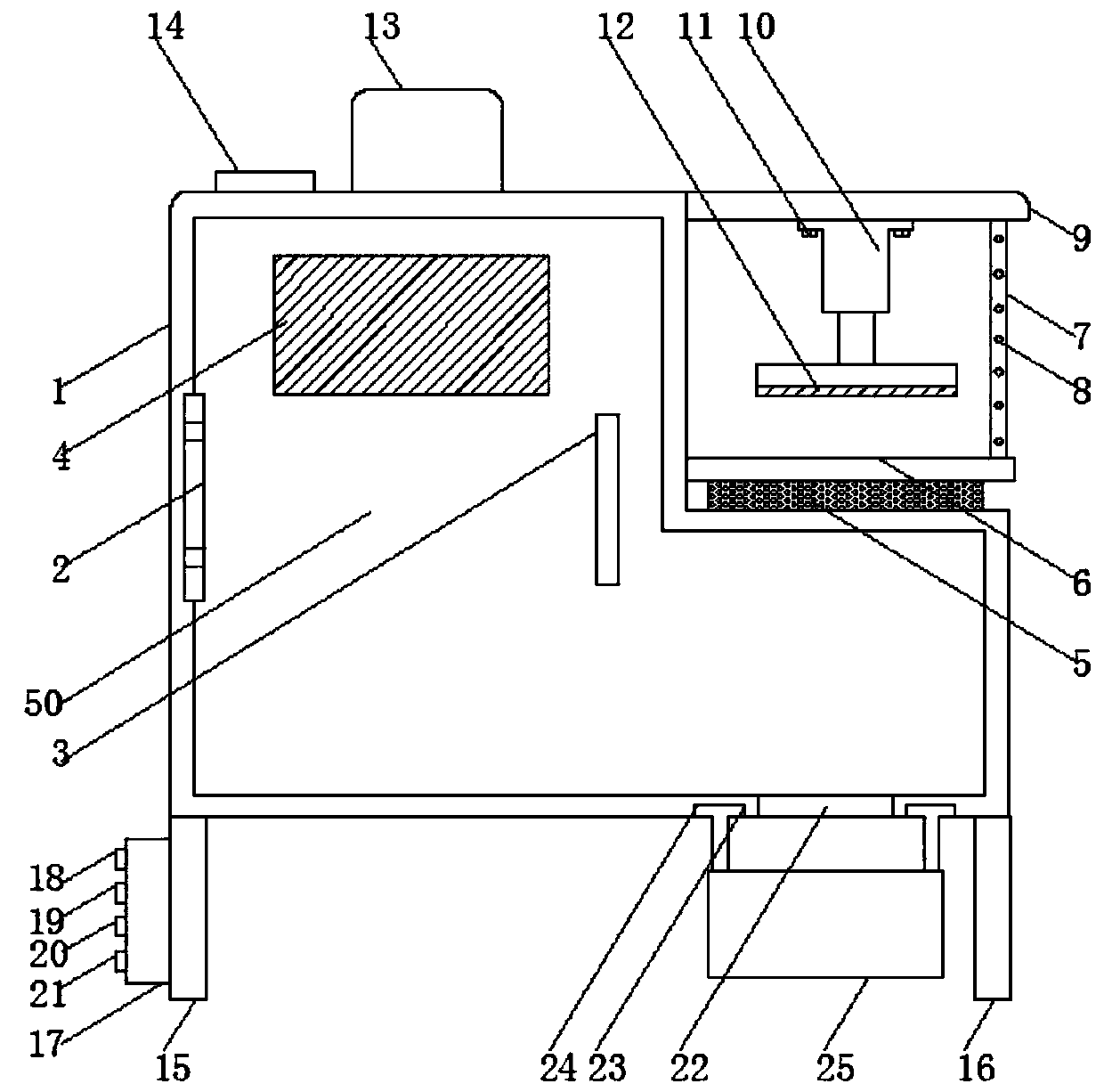

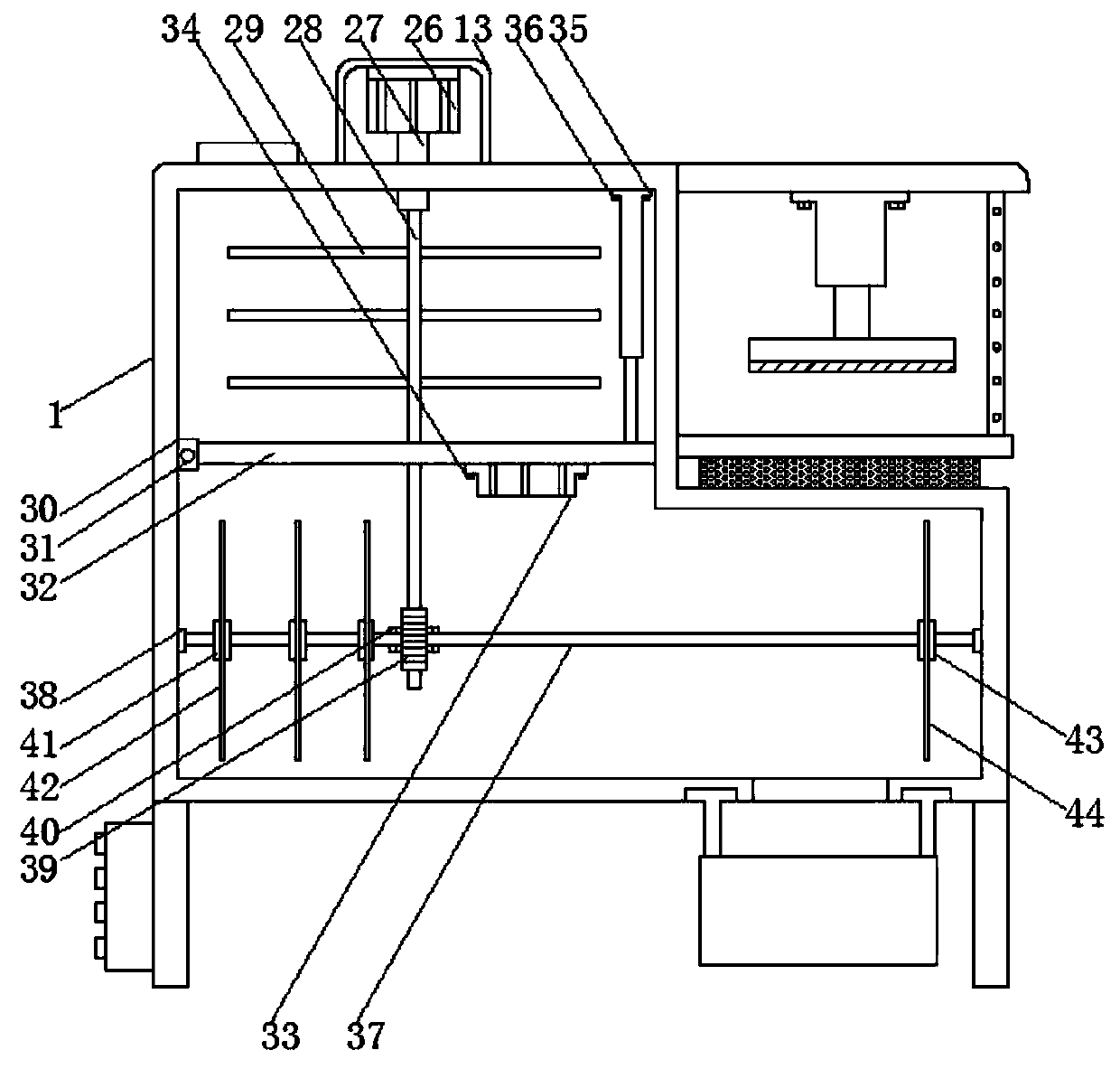

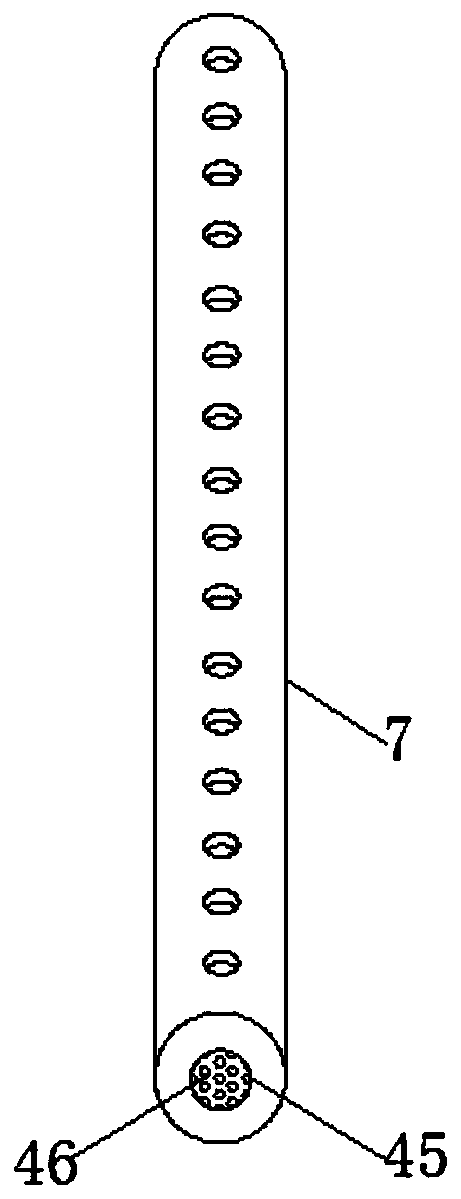

[0025] See Figure 1-4 , The present invention provides a technical solution: a sound-insulating cotton waste hammer crushing and winnowing integrated machine, comprising a device box 1, the top left side of the device box 1 is installed with a motor protection cover 13, the motor protection cover 13 A motor 26 is installed at the top of the inside. The bottom of the motor 26 is connected with a motor shaft 27. The bottom of the motor shaft 27 penetrates the device case 1 and is connected with a first rotating rod 28. The tops of the left and right sides of the first rotating rod 28 are welded. There is a crushing blade 29. The bottom of the first rotating rod 28 penetrates the first fixed plate 32 and is fixedly connected with a first bevel gear 40. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com