Finish machining system of rice

A technology for rice and broken rice, which is applied in solid separation, separation of solids from solids by air flow, and grain processing. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The application provides a rice finishing system, which is composed of a screening device, a rubber roller hulling device, a paddy separation device, a rice milling device, a polishing device, a packaging machine, and a storage bin connected in sequence. Between the device and the packaging machine, there are also sorting devices respectively connected with the two.

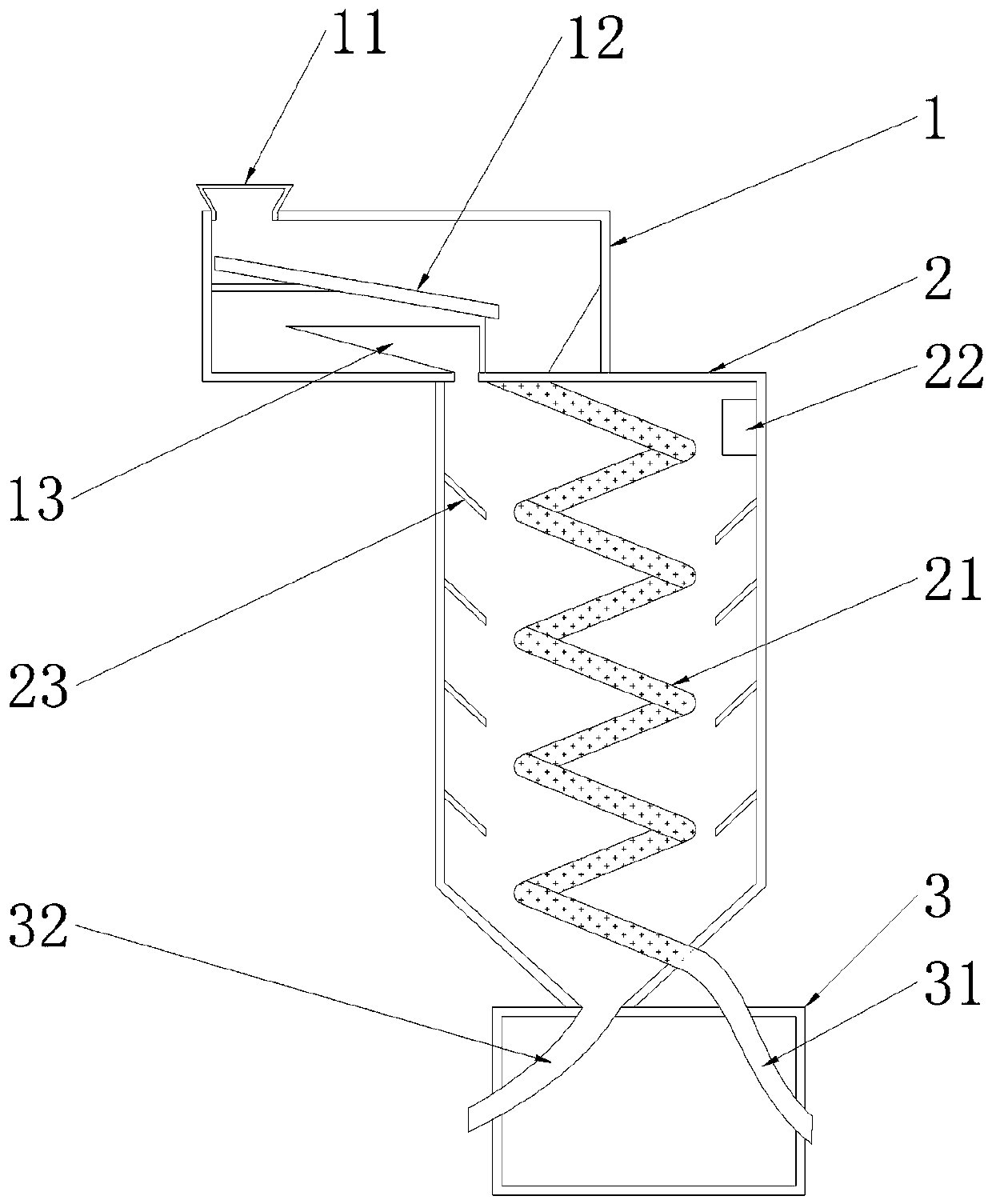

[0026] as attached figure 1 As shown, the sorting device includes a feeding chamber 1, a sorting chamber 2 and a discharging chamber 3 connected sequentially from top to bottom, the top of the feeding chamber 1 is provided with a feeding port 11, and a The broken rice receiving bucket 13 is placed under the vibrating screen 12 and the vibrating screen 12 . The sorting chamber 2 is welded with rice sieving tubes 22 arranged in a vertical spiral, an air conditioner 22 is also installed in the sorting chamber 2, and a downwardly inclined deceleration plate 23 is welded on the inner wall of the sorting chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com