Rice winnowing machine

A technology of air separator and rice, applied in dryers, non-progressive dryers, and separation of solids from solids by air flow, etc., can solve the problem of increasing the proportion of impurities, the rice is susceptible to moisture, and the effect of air separation is not good. and other problems, to achieve the effect of large air output, good wind selection effect, and improved wind selection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of those skilled in the art, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

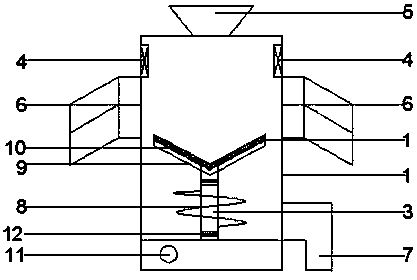

[0016] A rice winnowing machine includes: a case 1, a diffuser blade 2, a rotating shaft 3, and a dryer 4. The top of the cabinet 1 is provided with a feed inlet 5, a shell outlet 6 on the upper side, and a rice outlet 7 on the lower side; the shell outlet 6 is V-shaped and is installed on the top of the rotating shaft 3, which is hollow and parallel. The air diffuser 2 is connected; the dryer 4 is arranged on both sides of the inside of the cabinet 1; a spiral rotor 8 is installed on the rotating shaft 3, and a turntable 12 is provided on both ends of the spiral rotor 8 on the rotating shaft 3.

[0017] The rice winnowing machine according to claim 1, wherein the dryer 4 is specifically located above the shell outlet 6.

[0018] Further, the diffuser blade 2 includes a V-shaped fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com