Coarse filtration system for rice fine processing

A rice and coarse filtration technology, which is applied in the direction of sieving, solid separation, grille, etc., can solve the problem of incomplete separation of rice bran

Inactive Publication Date: 2018-02-09

GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The invention provides a coarse filtration system for rice finishing to solve the current problem of incomplete separation of rice bran

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the technical scheme of the present invention will be further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

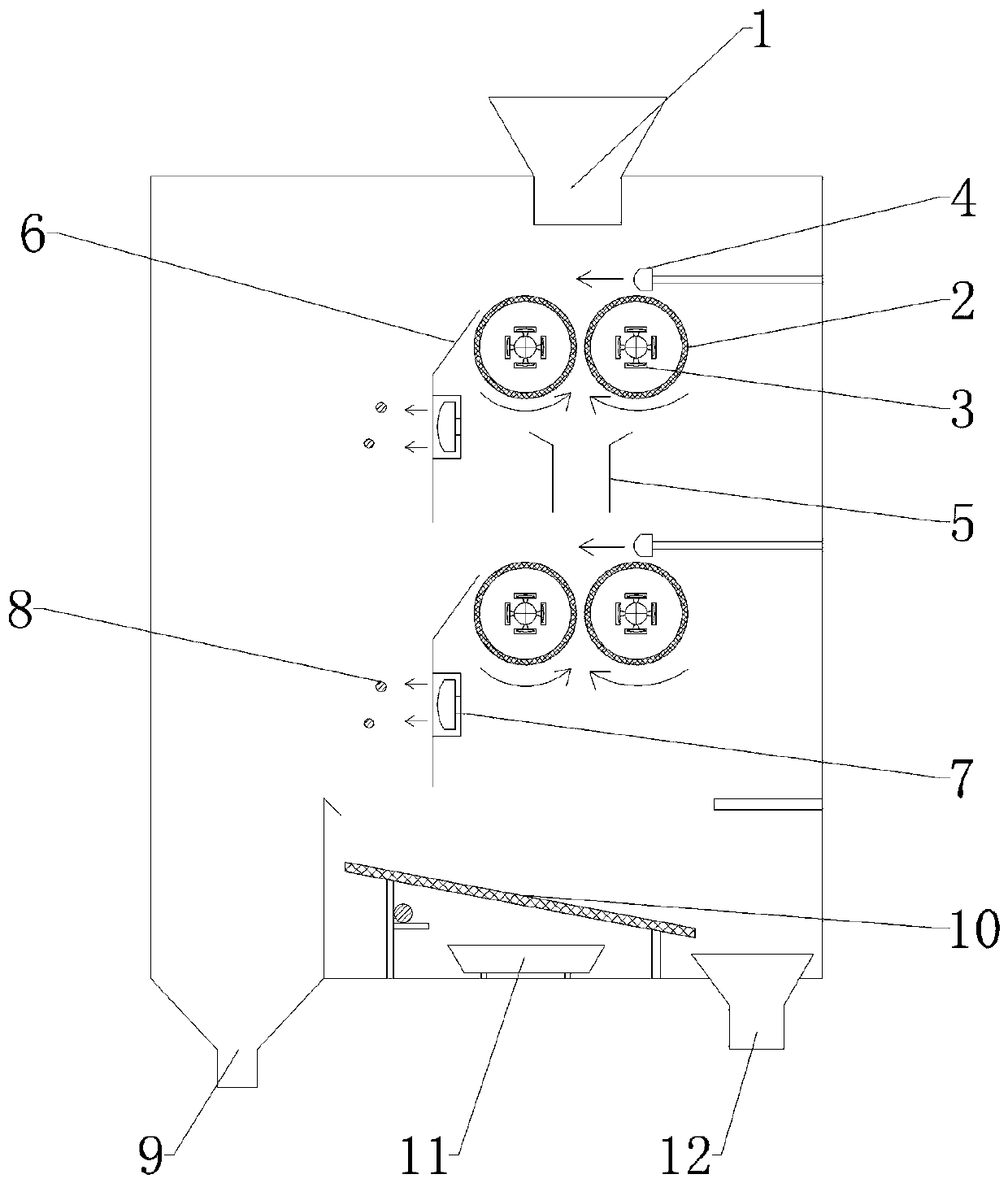

The invention discloses a coarse filtration system for rice fine processing in the technical field of grain processing. The coarse filtration system comprises a feeding bin, a screening bin and a discharging bin which are sequentially connected from top to bottom, wherein a first winnowing chamber and a second winnowing chamber which are arranged side by side in a left-and-right mode and communicate with each other are arranged in the screening chamber; two sets of roller winnowing mechanisms which are spaced and are aligned vertically are arranged in the first winnowing chamber; each roller winnowing mechanism comprises two left-and-right parallel rollers which are rotatably connected with the first winnowing chamber and driven by a motor; a plurality of first fans annularly arranged arearranged in each roller; a plurality of ventilation holes are formed in each roller; second fans for horizontally blowing air are arranged above the rollers; two third fans are arranged in the secondwinnowing chamber; and a rice discharging chamber and a bran discharging chamber are arranged in the discharging bin. According to the coarse filtration system for rice fine processing, through uniquestructural design, thorough separation of the rice from bran can be realized, and the processing of the rice in the later stage and the collection of the bran can be facilitated.

Description

technical field [0001] The invention belongs to the technical field of grain processing, and in particular relates to a coarse filter system for rice finishing. Background technique [0002] Rice (Rice) is a finished product made of rice after cleaning, husking, rice milling, and finished product finishing. Rice is the basic food for supplementing nutrients. In addition to being rich in carbohydrates, it also contains protein, fat, vitamins and 11 kinds of minerals, which can provide comprehensive nutrition for the human body. It is the main food of the southern people. [0003] After the rice is cleaned and husked, white rice grains are obtained. At this time, the rice grains are rough, commonly known as "brown rice". Brown rice is used for cooking. The cooking time is long, the color is dark, the viscosity is poor, and the taste is not good. Because the cortex of brown rice is complete, water absorption and expansion are not strong, resulting in poor eating quality. The...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B07B9/00B07B1/28B07B4/06B07B11/00

CPCB07B9/00B07B1/28B07B4/06B07B11/00

Inventor 谭仕波

Owner GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com