Tea winnower

A winnowing machine and tea technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of incomplete removal of impurities, inability to control wind speed, poor winnowing effect, etc. problems, to achieve the effect of complete removal of impurities, stable wind speed and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

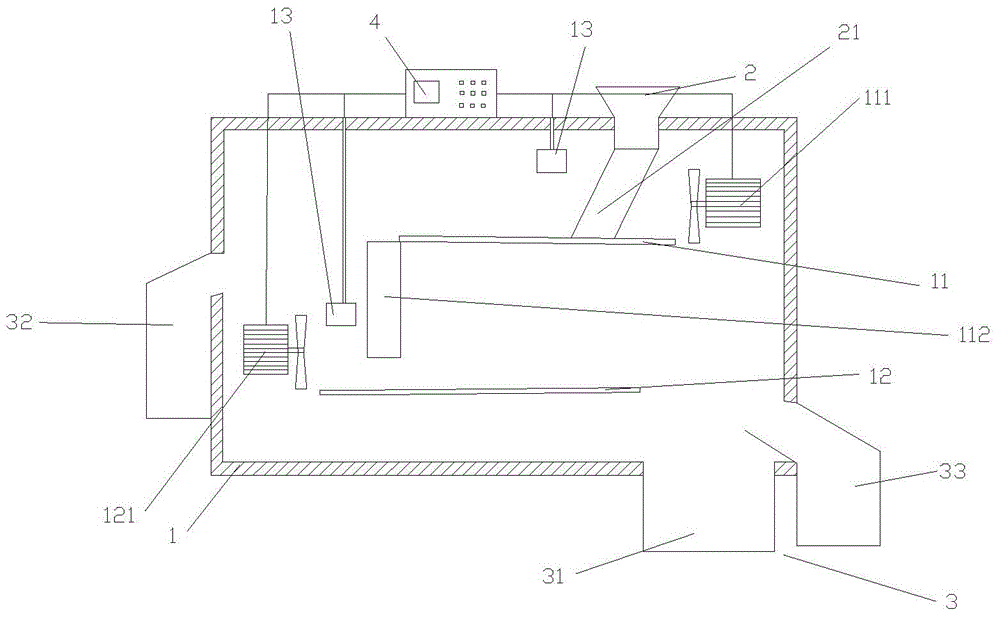

[0014] Such as figure 1 As shown, the tea winnowing machine includes a cylindrical body 1, a feeding device 2 arranged above the body 1, a discharge device 3 arranged below the body 1, a controller 4 arranged on the body 1, and a device inside the body 1. There are two passages A11 and B12 along the direction of the body 1 axis. The passages A11 and B12 are respectively equipped with wind speed sensors 13 for detecting the wind speed in the passages A11 and B12. The wind speed sensors 13 are connected to the controller 4, and the passage A11 One end is provided with a fan A111, and the other end is provided with an air duct 112 for transporting tea leaves to the channel B12. One end of the channel B12 is provided with a fan B121, and the other end is connected to the discharge device 2. The fan A111 and the fan B121 are respectively located in the machine body 1 and the direction of the fan A111 is opposite to that of the fan B121, and the fan A111 and the fan B121 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com