Multi-level heat exchange split-building type catalytic oxidation system and processing method thereof

A catalytic oxidation and heat exchange system technology, which is applied to the multi-stage heat exchange split-type catalytic oxidation system and its treatment field, can solve the problems of inability to fully realize energy recovery and large energy consumption, save additional energy, and achieve cleanliness. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

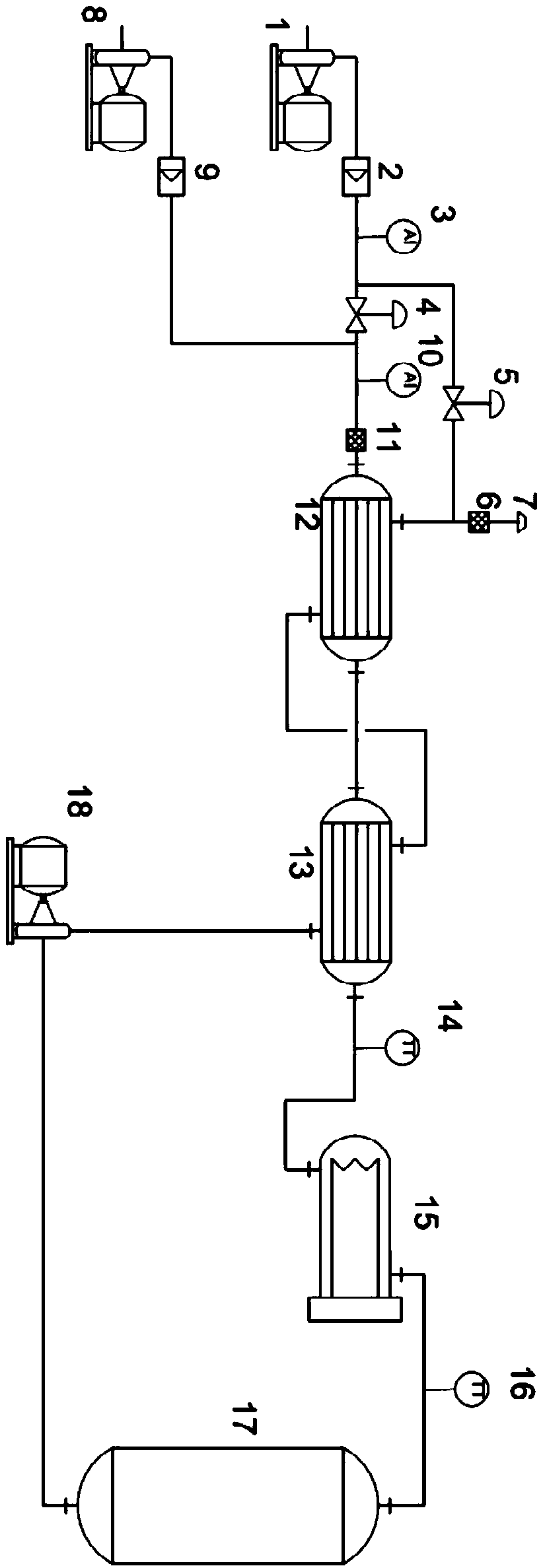

[0039] A separate catalytic oxidation system with multi-stage heat exchange, such as figure 1 As shown, it includes exhaust gas fan 1, supplementary air fan 8, heat exchange system, electric heater 15, catalytic oxidizer 17, induced draft fan 18, control system, safety system and connecting pipelines, wherein, exhaust gas fan 1 and supplementary air fan 8 They are arranged in parallel, and are sequentially connected to the heat exchange system, the electric heater 15 and the catalytic oxidizer 17 through pipelines.

[0040] The connecting pipe from the exhaust fan 1 to the heat exchange system is additionally provided with a venting pipe leading to the outside.

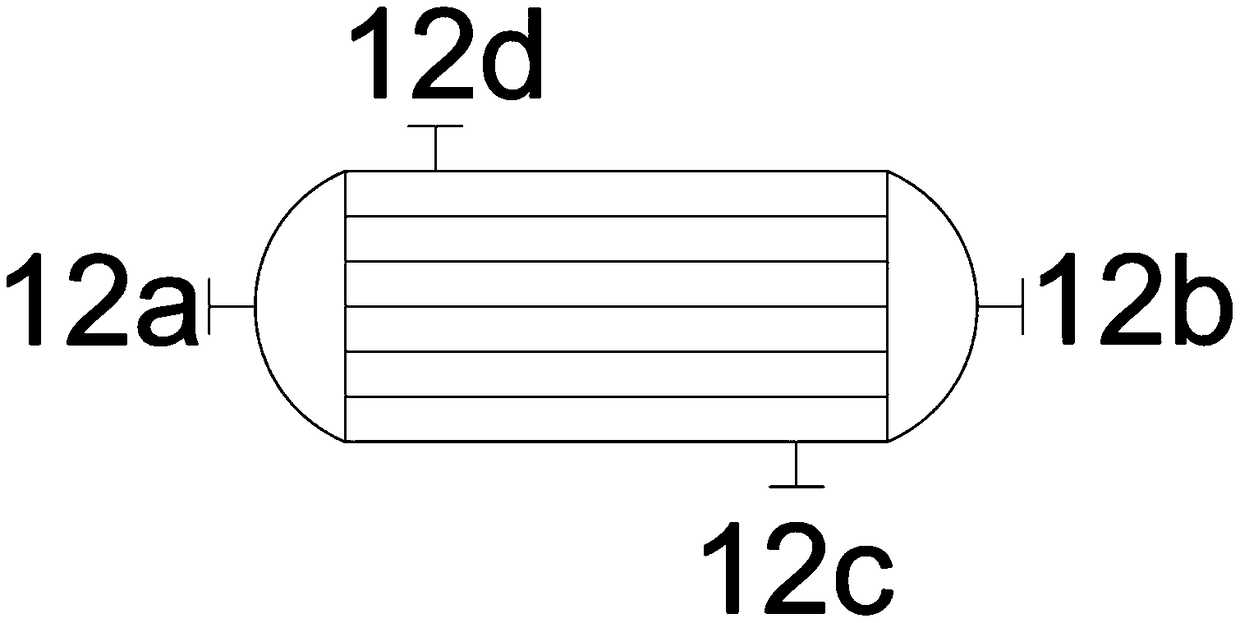

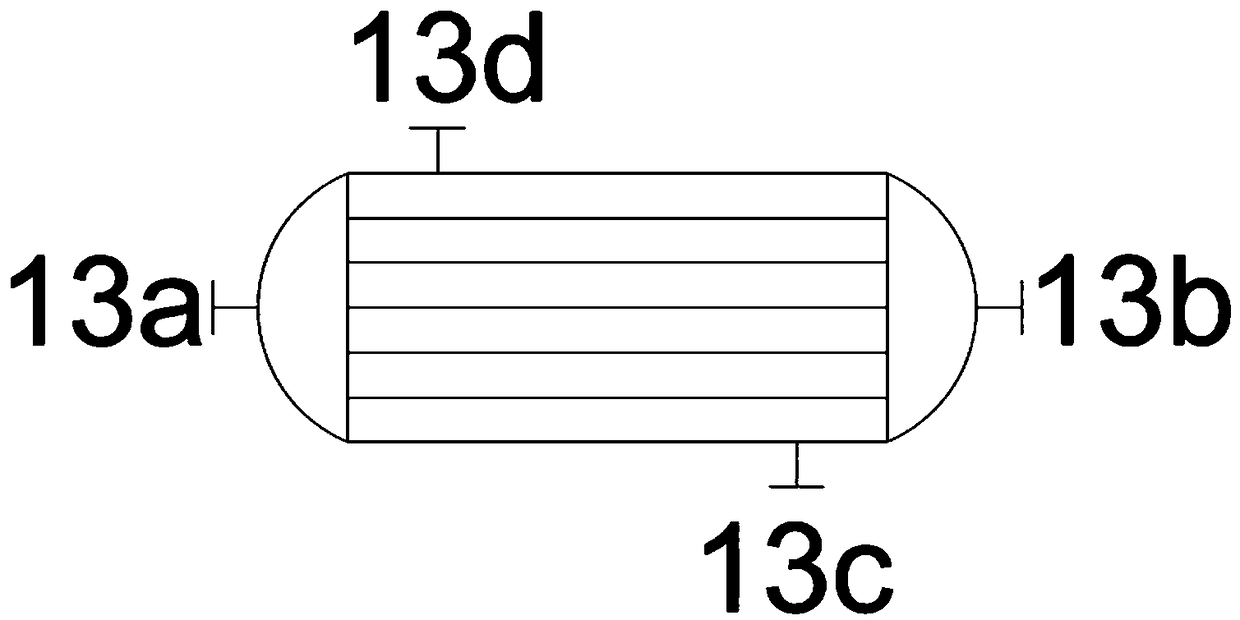

[0041] The heat exchange system includes a primary heat exchanger 12 and a secondary heat exchanger 13 connected in sequence, such as figure 2 and image 3 As shown, the two have the same structure, and both are provided with an exhaust gas inlet, an exhaust gas outlet, an exhaust gas inlet and an exhaust gas outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com