Downdraft type fixed bed gasifying steam power generation co-production device and process

A technology of fixed bed and production process, which is applied in the direction of gasification process, steam engine device, steam application, etc. It can solve the problems of small gasification power generation scale, high fuel cost, and large fuel transportation radius, so as to reduce operating costs and investment, The effect of improving economic efficiency and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

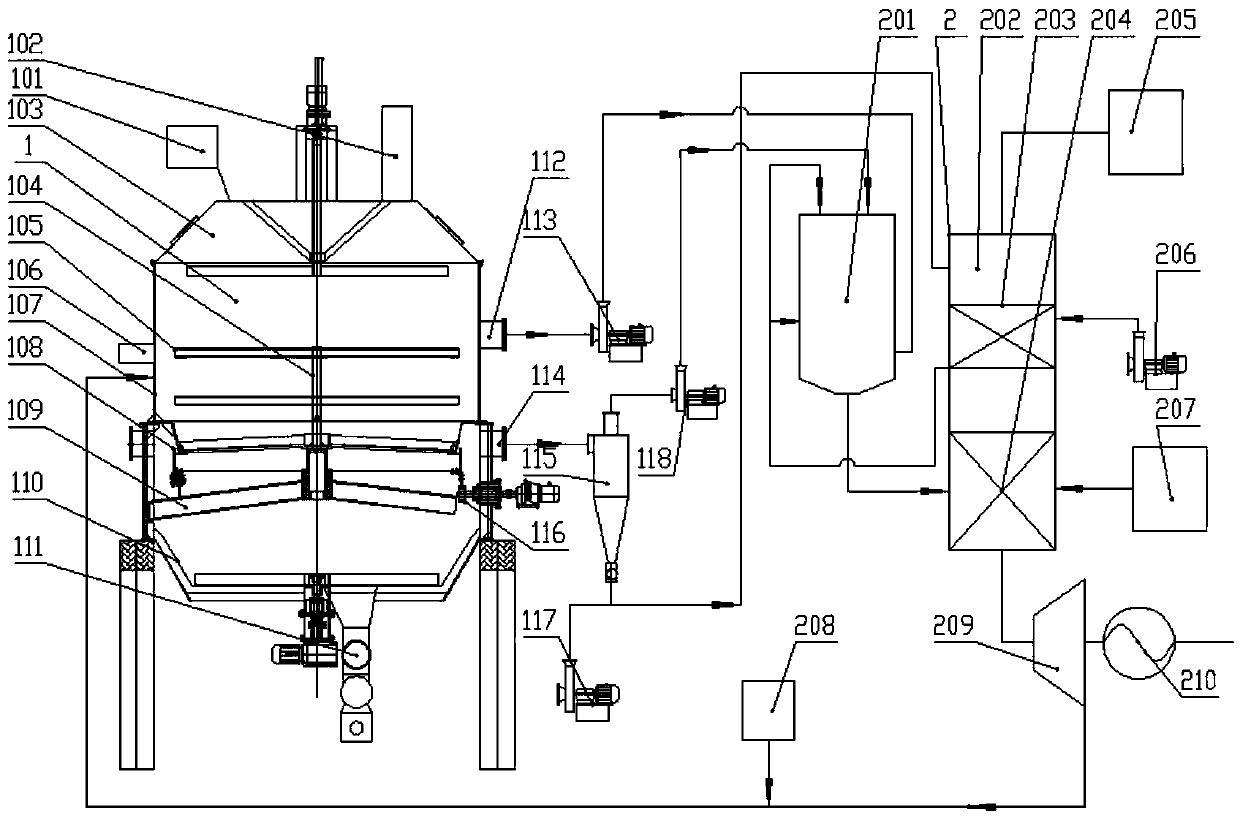

[0033] The raw material of almond husk is added from the top 103 of the furnace by the feeding device 101, the primary air required for almond husk gasification is sucked in by the primary tuyere 102, and the almond husk is pyrolyzed and gasified with the air under the radiation of the high temperature materials in the intermediate furnace body 107 The reaction produces biomass high-temperature pyrolysis gas and biochar with higher tar content. The pyrolysis gas at 330°C is drawn from the middle of the gasification furnace by the pyrolysis gas fan 113 and sent to the gas combustion chamber 201 for combustion. The secondary air used for biochar activation and ammonia-carrying water vapor enters the intermediate furnace body 107. The mass ratio of almond shell to ammonia is 260kg / kg, which reacts with biochar to obtain nitrogen-containing activated carbon with desulfurization characteristics and gasification Gas. The gasification gas at 460°C drawn from the lower part of the gasi...

Embodiment 2

[0035] The coconut shell raw materials are added from the furnace top 103 by the feeding device 101, the primary air required for coconut shell gasification is sucked by the primary tuyere 102, and the coconut shell is pyrolyzed and gasified with the air under the radiation of the high temperature materials in the intermediate furnace body 107 The reaction produces biomass high-temperature pyrolysis gas and biochar with higher tar content. The high-temperature pyrolysis gas is drawn from the middle of the gasifier by the pyrolysis gas fan 113 and sent to the gas combustion chamber 201 for combustion. The secondary air used for biochar activation and ammonia-carrying water vapor enters the intermediate furnace body 107. The mass ratio of coconut shell to ammonia is 350kg / kg, which reacts with biochar to obtain nitrogen-containing activated carbon with desulfurization characteristics and gasification Gas. The 520℃ gasification gas extracted from the lower part of the gasification...

Embodiment 3

[0037] Sawdust raw materials are added from the furnace top 103 by the feeding device 101, and the primary air required for the gasification of the sawdust is sucked in by the primary tuyere 102. The sawdust undergoes pyrolysis and gasification reaction with the air under the radiation action of the high-temperature materials in the intermediate furnace body 107. The high-temperature pyrolysis gas and biochar of biomass with higher tar content are drawn from the middle of the gasifier by the pyrolysis gas fan 113 and sent to the gas combustion chamber 201 for combustion. The secondary air used for biochar activation and ammonia-carrying water vapor enters the intermediate furnace body 107. The mass ratio of coconut shell to ammonia gas is 370kg / kg, which reacts with biochar to obtain nitrogen-containing activated carbon with desulfurization characteristics and gasification Gas. The 420°C gasification gas extracted from the lower part of the gasifier carries powdered nitrogen-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com