Liquified gas or compressed natural gas automobile fuel gas multipoint sequencial jet system

A compressed natural gas and sequential injection technology, applied in fuel injection control, electrical control, engine control, etc., can solve problems such as unsatisfactory control accuracy, responsiveness, and unsatisfactory gas economy, and achieve stable operation and good applicability , the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

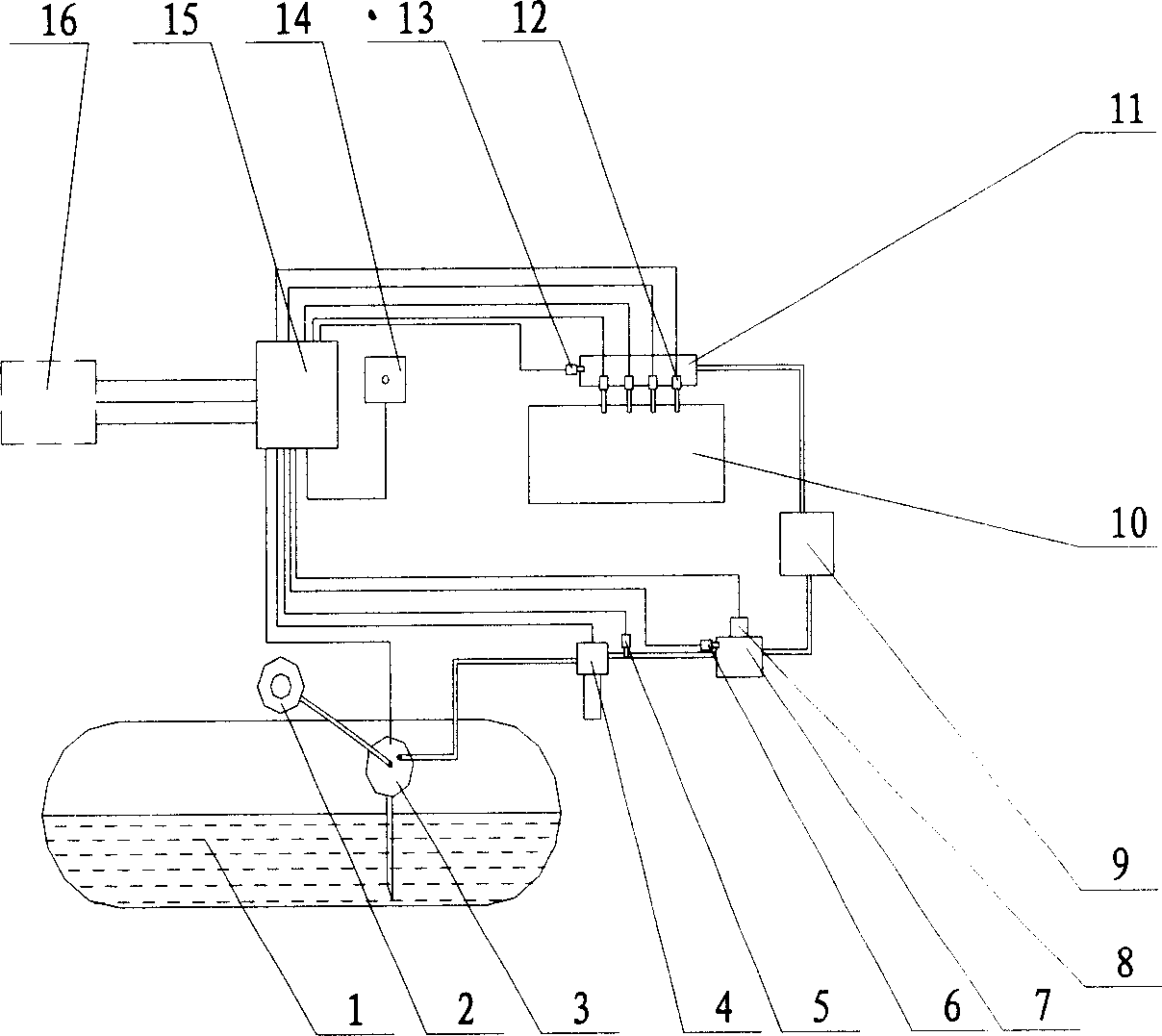

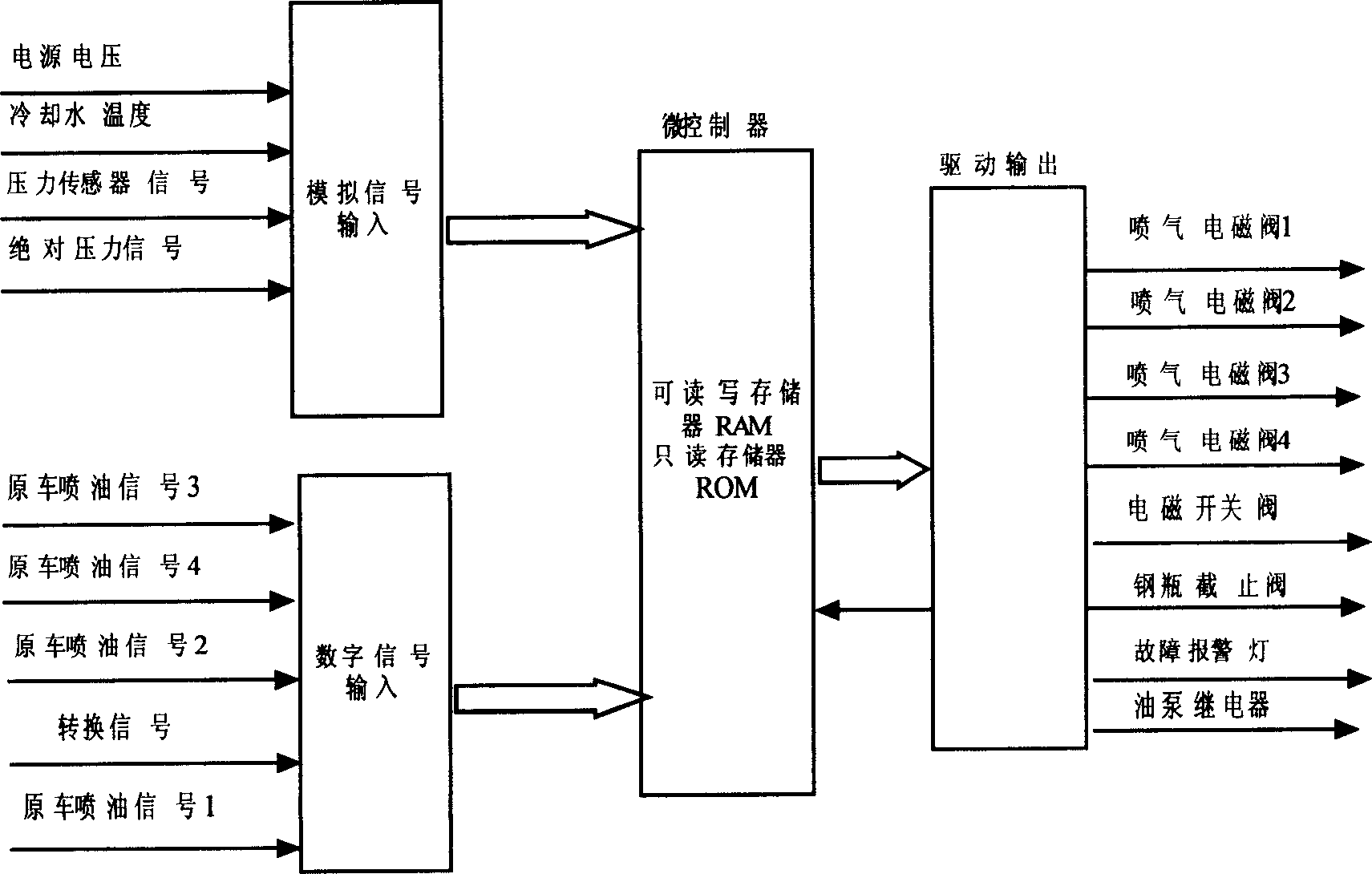

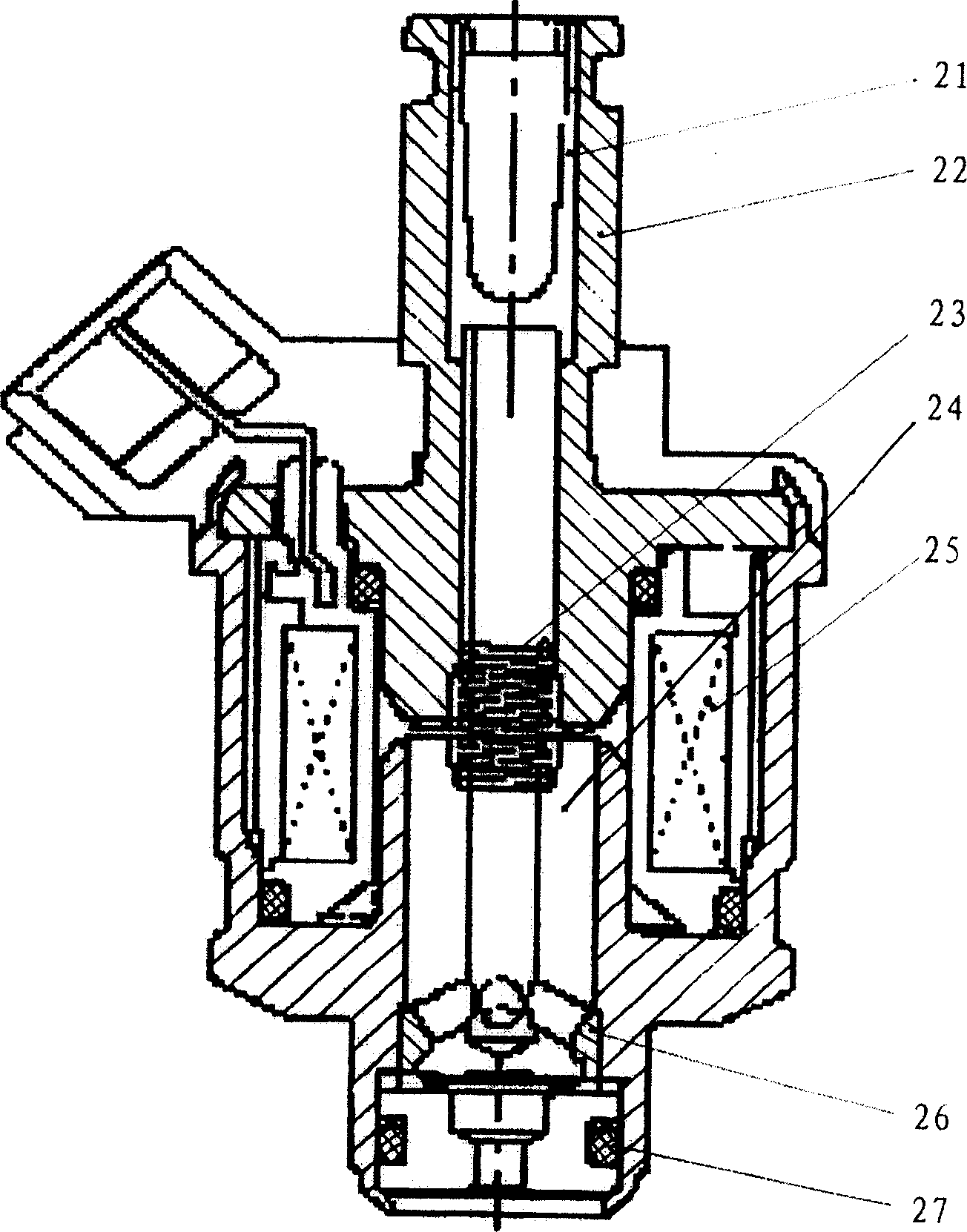

[0016] see figure 1 , a liquefied gas or compressed natural gas vehicle gas multi-point sequential injection system, including a steel cylinder 1, a gas filling combination valve 2, an integrated valve 3, an electromagnetic switch valve 4, a pressure sensor 5, a water temperature sensor 6, a pressure reducer 7, and a stop valve 8. Gas filter 9, gas common rail pipe 11, gas injection solenoid valve 12, absolute pressure sensor 13, transfer switch 14, controller 15 and original vehicle controller 16. The integrated valve 3 is set on the steel cylinder 1 and connected with the steel cylinder 1 with a high-pressure pipe, the inlet of the integrated valve 3 is connected with the combined gas filling valve 2 with a high-pressure pipe, and the outlet of the integrated valve 3 is connected with the inlet of the electromagnetic switch valve 4 with a high-pressure pipe. The outlet of the electromagnetic switch valve 4 is connected with the pressure reducer 7 with a high-pressure pipe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com