System and method for treating domestic garbage and sewage sludge

A technology for domestic waste and sewage, which is used in the pyrolysis treatment of sludge, special forms of dry distillation, petroleum industry, etc. Improve productivity and quality, achieve clean emissions, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

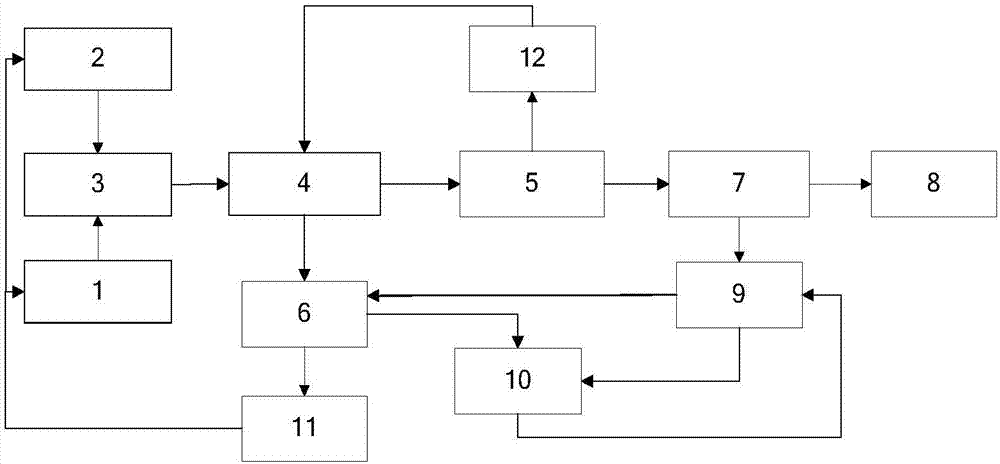

Method used

Image

Examples

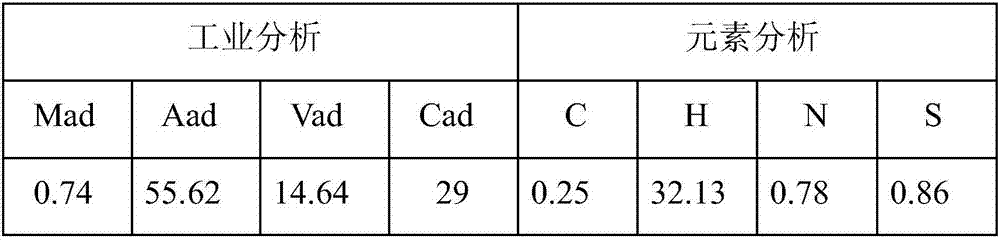

Embodiment 1

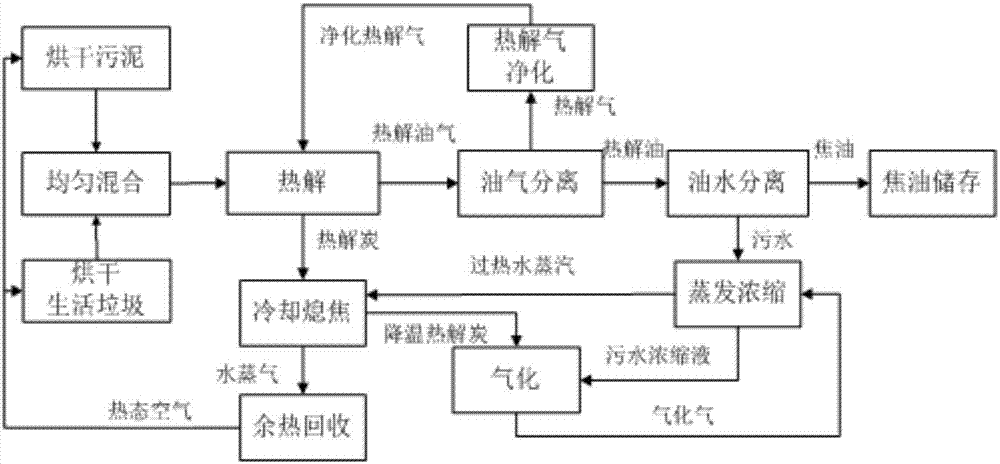

[0055] Send the domestic garbage into the garbage crushing dryer and crush it to a particle size below 50mm, and use the waste heat supplied by the waste heat recovery device to dry the crushed garbage so that the moisture content is reduced from 48wt% to 40wt% (wt% is mass percentage), and the waste water generated is sent to the sewage evaporative concentrator for treatment.

[0056] The sludge is sent to the sludge dryer, and the waste heat supplied by the waste heat recovery device is used to reduce the water content from 75wt% to 40wt%, and the generated waste water is sent to the sewage evaporative concentrator for treatment.

[0057] The crushed and dried domestic garbage and sludge are sent to the mixing feeder to mix evenly, and then sent to the rotary bed pyrolysis furnace for pyrolysis. The rotary bed pyrolysis furnace is heated by regenerative radiant tubes, and the gas used in the radiant tubes is purified pyrolysis gas after treatment in the pyrolysis gas decokin...

Embodiment 2

[0071] The difference between this embodiment and embodiment 1 is:

[0072]The dried garbage and sludge enter the rotary bed pyrolysis furnace through two feeders respectively, and the sludge feeder is located in front of the garbage feeder, and the sludge feeding speed is twice the garbage feeding speed. The mass ratio of garbage to sludge is 1:2. After entering the rotary bed pyrolysis furnace, the effect of layered distribution of sludge and garbage is formed. Compared with Example 1, the yield of the pyrolysis gas in this example is increased by 2.6%, and the calorific value is increased by 1.17 times. The specific components of the purified pyrolysis gas are shown in Table 3.

[0073] Table 3 Components of Purified Pyrolysis Gas

[0074] components

Embodiment 3

[0076] The difference between this embodiment and embodiment 1, 2 is:

[0077] The dried garbage and sludge are firstly mixed evenly through the mixer, the mixing ratio of garbage and sludge is 1:3, and the mixed material enters the rotary bed pyrolysis furnace through the screw feeder for pyrolysis, and the generated pyrolysis gas The yield reaches 48.7%, and the calorific value reaches 4400kcal / kg. Specifically, the components of the purified pyrolysis gas are shown in Table 4.

[0078] Table 4 Components of Purified Pyrolysis Gas

[0079] components

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com