Water recyclable superheated steam drying lignite system and process method thereof

A technology of superheated steam and process method, which is applied in the direction of drying solid materials, drying gas arrangement, drying, etc., which can solve the problems of high coal powder content in wet tail gas and complex purification process of the system, so as to achieve clean discharge and avoid back mixing , Enhance the effect of flushing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

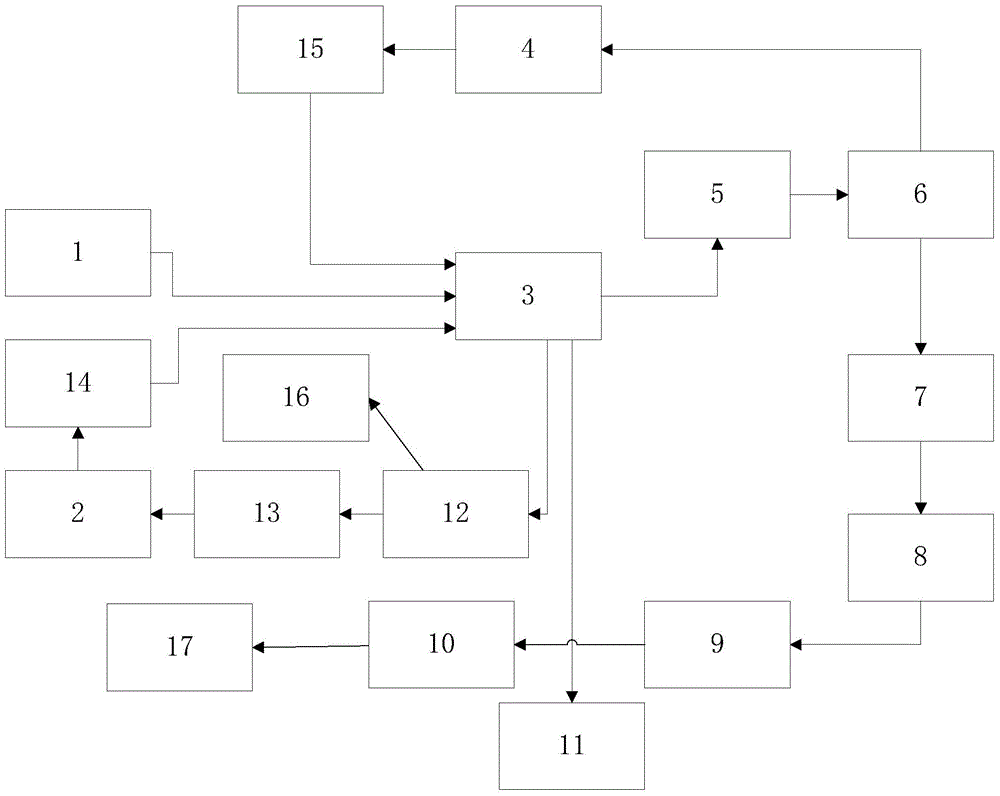

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] Such as figure 1 Shown, a kind of superheated steam drying lignite system that can recover water comprises steam drier 3, and described steam drier 3 is respectively connected with wet-carrying gas circulation unit, water recovery unit and saturated condensed water flashing unit;

[0044] The moisture-carrying gas circulation unit includes an electric heater 4, the input end of the electric heater 4 is connected to a bag filter 6, the bag filter 6 is connected to a cyclone dust collector, and the cyclone dust collector 5 is connected to a steam drying The output end of the device 3 is connected, and the output end of the electric heater 4 is connected with the input end of the steam dryer 3;

[0045] The water recovery unit includes a cyclone dust collector 5, a bag filter 6, a wet electrostatic precipitator 7, an air cooling device 8, a water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com