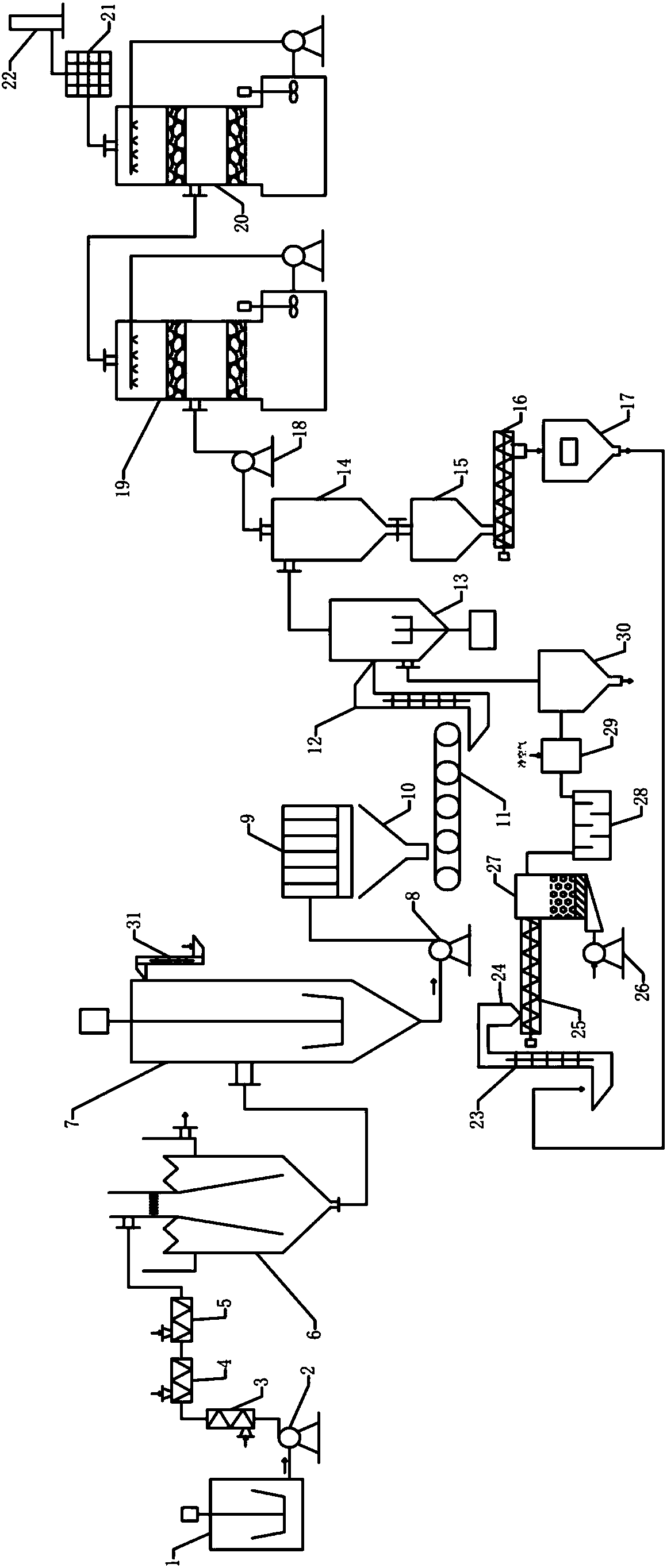

Self-heat-supply type sludge dewatering and drying method and system

A drying method and drying system technology, applied in water/sludge/sewage treatment, combustion method, sludge treatment, etc., can solve problems such as reducing the final volume, improve the depth of dehydration, reduce dosage, and reduce chloride ion content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment is for treating sludge from a paper mill. The paper mill sludge is composed of primary sedimentation tank sludge, aerated secondary sedimentation tank sludge and deep decolorization treatment sludge. The comprehensive sludge concentration is 1.8~2.0wt.%. The average calorific value is 3200kcal / kg, and the average sludge production (equivalent to 100%) is 25 tons / day.

[0070] In this example, sodium polyaluminosilicate, polyaluminum chloride, and cationic polyacrylamide are used as flocculants, which are respectively added to three static mixers connected in series on the sludge pipeline, and mixed with sludge to produce flocculation reaction, polysilicon The added mass of sodium aluminate, polyaluminum chloride and cationic polyacrylamide is 2.5wt.%, 3wt.% and 0.35wt.% of the absolute dry sludge, respectively, and the flocculated sludge fully mixed with the agent is introduced into the sludge The dehydration tower 6 dehydrates, and the sewage overflowi...

Embodiment 2

[0073] This embodiment is used to treat a certain municipal domestic sewage sludge. The sludge of this plant is mainly composed of activated sludge from the aerated secondary sedimentation tank and deep decolorization treatment sludge. kg, the average amount of sludge (equivalent to 100%) is 45 tons / day. Add 30% sodium aluminosilicate, 10% polyaluminum chloride and 0.2% cationic polyacrylamide solution to the three static mixers connected in series on the sludge pipeline, and mix with the sludge to produce flocculation In the reaction, the added mass of sodium aluminosilicate, polyaluminum chloride and cationic polyacrylamide were respectively 2.5 wt.%, 3 wt.% and 0.35 wt.% of the absolute dry sludge, and the The flocculated sludge is introduced into the sludge dehydration tower for dehydration, and the sewage overflowing from the upper part of the tower flows back to the sewage treatment system for retreatment. The powdery sludge conditioner is 6500kcal / kg, and the addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com