Efficient method and device for removal of acidic gas from fume or coal gas

A technology for acid gas and flue gas, which is applied in the field of acid gas purification devices and high-efficiency purification devices. It can solve the problems of frequent updates, reduced deacidification efficiency, and large consumption of deacidification agents, and achieves clean discharge of corrosion, corrosion prevention, and efficient deacidification. The effect of removing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

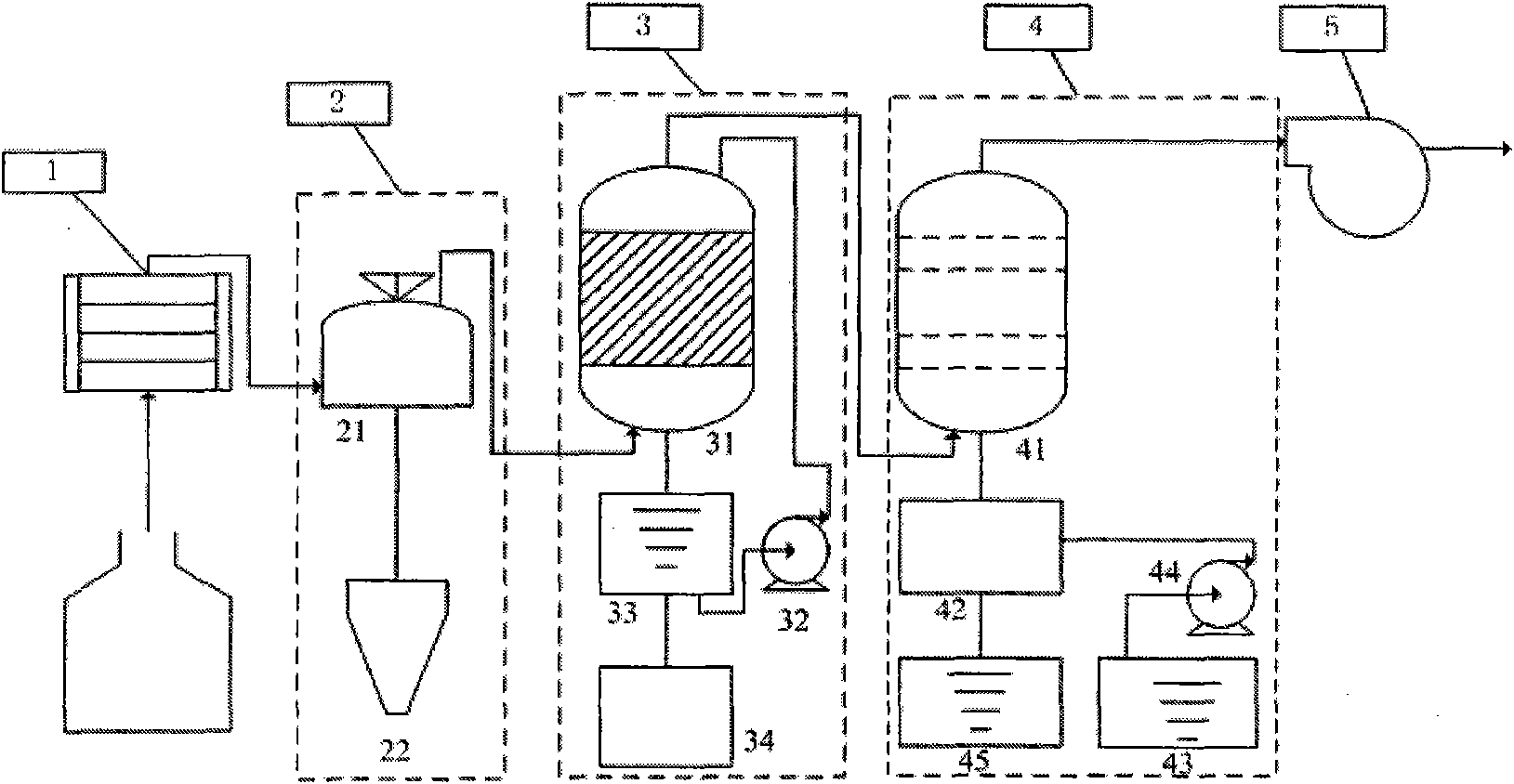

[0027] figure 1 It is a schematic diagram of a high-efficiency device for removing acid gases in flue gas or coal gas. In the figure, the high-efficiency device for removing acid gas in flue gas or coal gas includes: acid-resistant cooling device 1, acid-resistant bag dust removal system 2, primary deacidification system 3, secondary deacidification system 4, and induced draft fan 5. The acid-resistant cooling device 1, the acid-resistant bag dust removal system 2, the primary deacidification system 3, the secondary deacidification system 4, and the induced draft fan 5 are sequentially connected in series through flue gas or gas pipelines. The induced draft fan 5 is arranged at the end of the flue gas or gas pipeline, and is used to discharge the purified flue gas or gas to the outside. Driven by the induced draft fan 5, the flue gas or coal gas enters the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com