Harmless fixed bed thermolysis system for zinc and cadmium super accumulator plant

A super-accumulation and harmless technology, applied in the direction of solid waste removal, etc., can solve problems such as unfavorable recovery, loss of heavy metals in bottom ash, etc., to increase patency, improve reaction efficiency, and facilitate harmless disposal or recycling. possible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

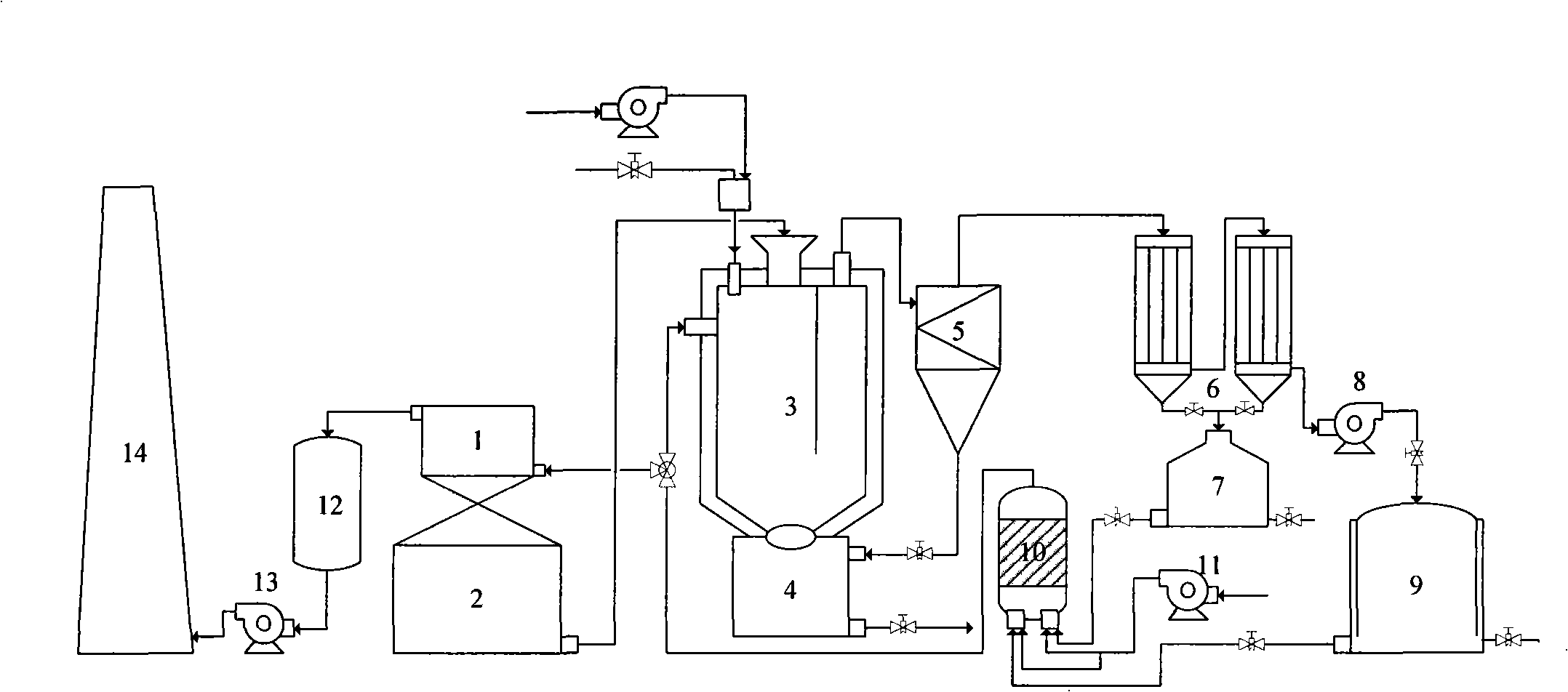

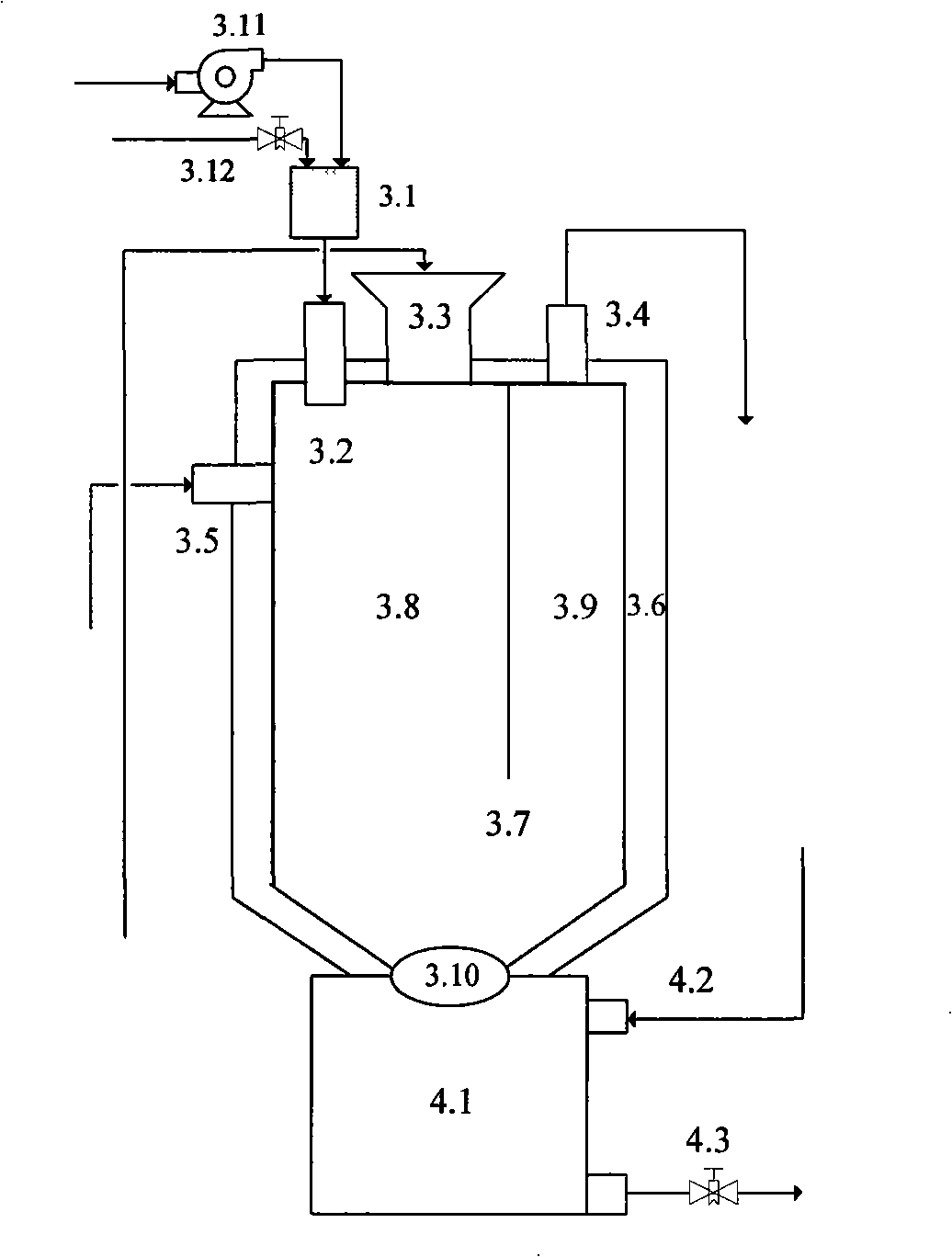

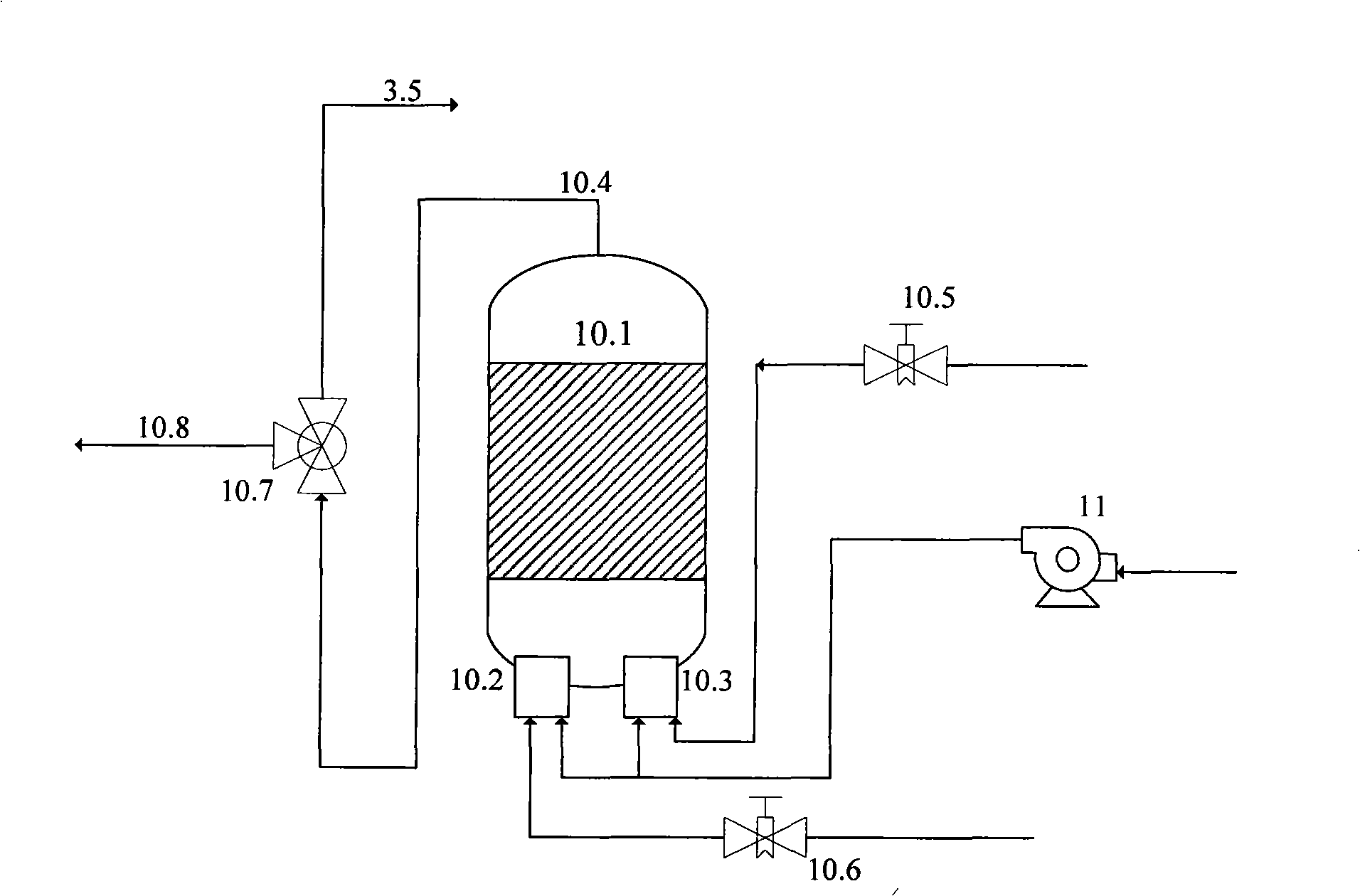

[0020] Such as figure 1 As shown, the present invention comprises: a raw material drying chamber 1, connected to a raw material bin 2, a pyrolysis furnace 3 connected to the raw material bin 2, a coke collection box 4 at the bottom of the pyrolysis furnace 3, and a pyrolysis gas outlet at the top of the pyrolysis furnace 3 3.4 The connected cyclone separator 5, the water cooling system 6 connected with the cyclone separator 5, the oil liquid product collection box 7 at the lower part of the water cooling system 6, the induced draft fan 8 and the gas storage tank 9 on the flue gas outlet side of the water cooling system, and the gas storage tank The tank 9 is connected with the incineration comprehensive utilization system 10, the outlet of the incineration comprehensive utilization system 10 is connected with the raw material drying chamber 1 and the pyrolysis gas incineration flue gas inlet 3.5 through the three-way valve 10.7, and the flue gas outlet of the raw material dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com