Waste heat recovery condensation water-saving device

A technology of water-saving device and waste heat recovery, which is applied in the direction of combination device, steam condensation, dispersed particle separation, etc., can solve the problems of social and enterprise impact, power plant can not be normal production, etc., to solve the problem of gypsum rain and avoid the problem of ash plugging and scaling , to ensure the effect of long-term work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

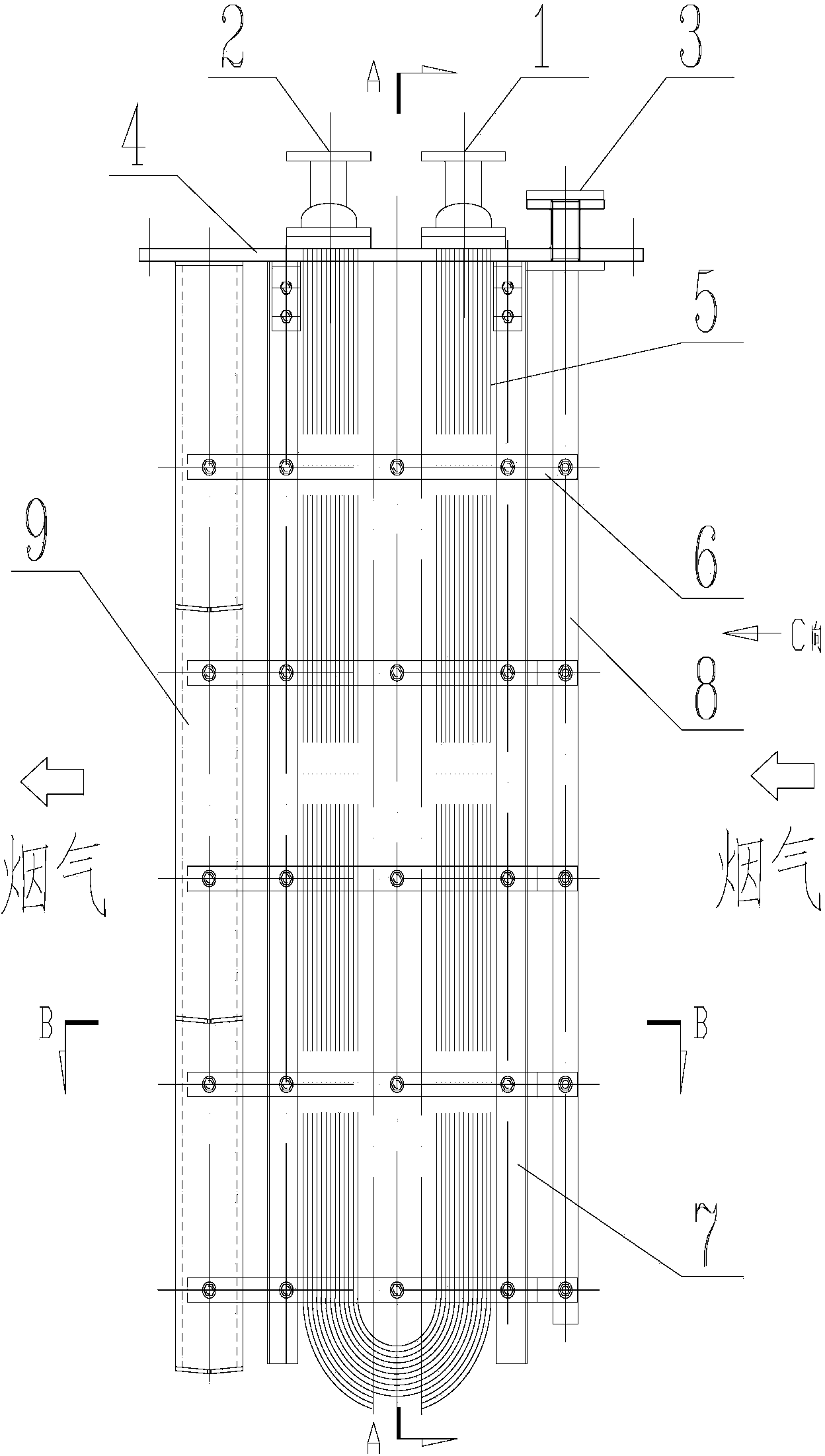

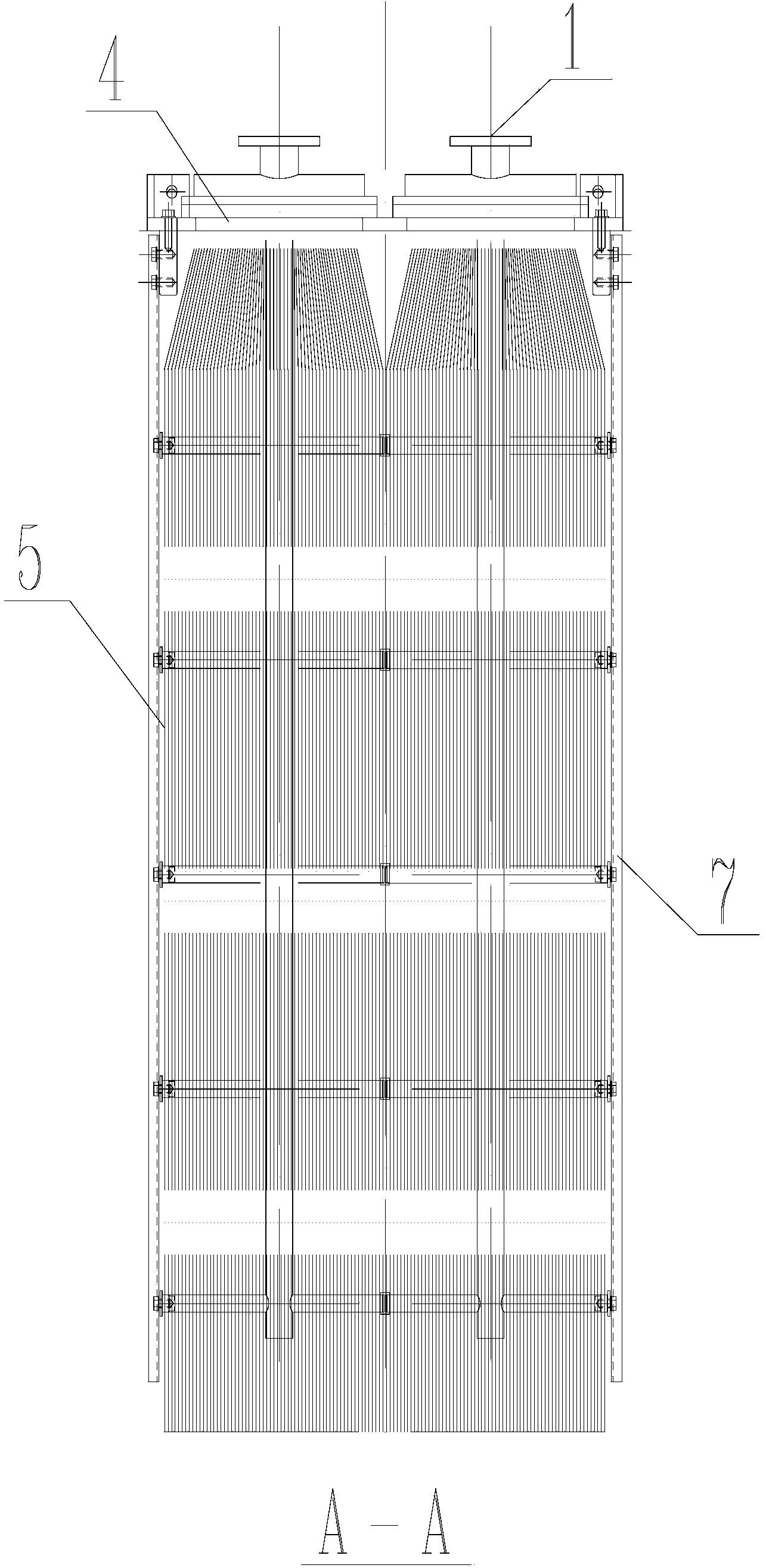

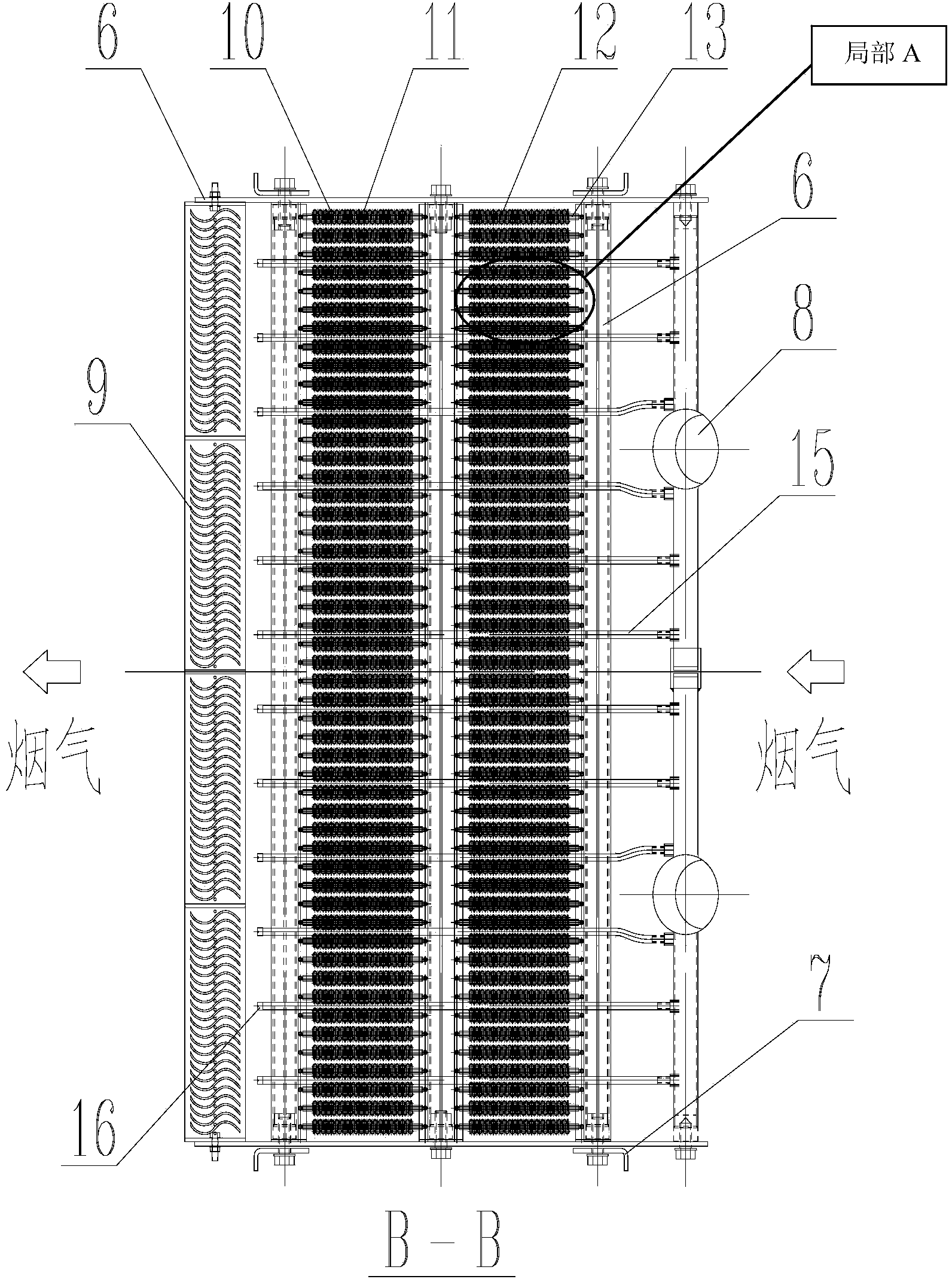

[0038] In the following, the waste heat recovery condensation water saving device of the present invention will be further explained in detail in conjunction with the accompanying drawings and embodiments.

[0039] Such as Figure 1~4 As shown, the waste heat recovery condensation water-saving device of the present invention is generally used in the energy and environmental protection industry, and is arranged in the flue behind the wet desulfurization device. It includes a refrigerant water inlet 1, a refrigerant water outlet 2, a flushing water interface 3, and a top cover 4 , flow blocking heat exchange tube grid 5, tube grid support beam 6, tube grid support column 7, flushing jellyfish tube 8, water collection drop catcher 9, heat exchange tube 10.

[0040] The heat exchange tube 10 is a U-shaped tube arranged perpendicular to the direction of the flue, its water inlet end communicates with the refrigerant water inlet 1 , and its water outlet end communicates with the ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com