Method for denitration of coal-fired power plant boiler through synergistic recycling of sludge and coal slime

A coal-fired power plant, resource utilization technology, applied in the direction of combustion methods, chemical instruments and methods, incinerators, etc., can solve the problems of large capacity and large dosage, high sulfur content, high ash content, low fixed carbon content, etc., and achieve improvement The effect of denitrification efficiency, reduction of NOx emissions, and acceleration of fuel combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

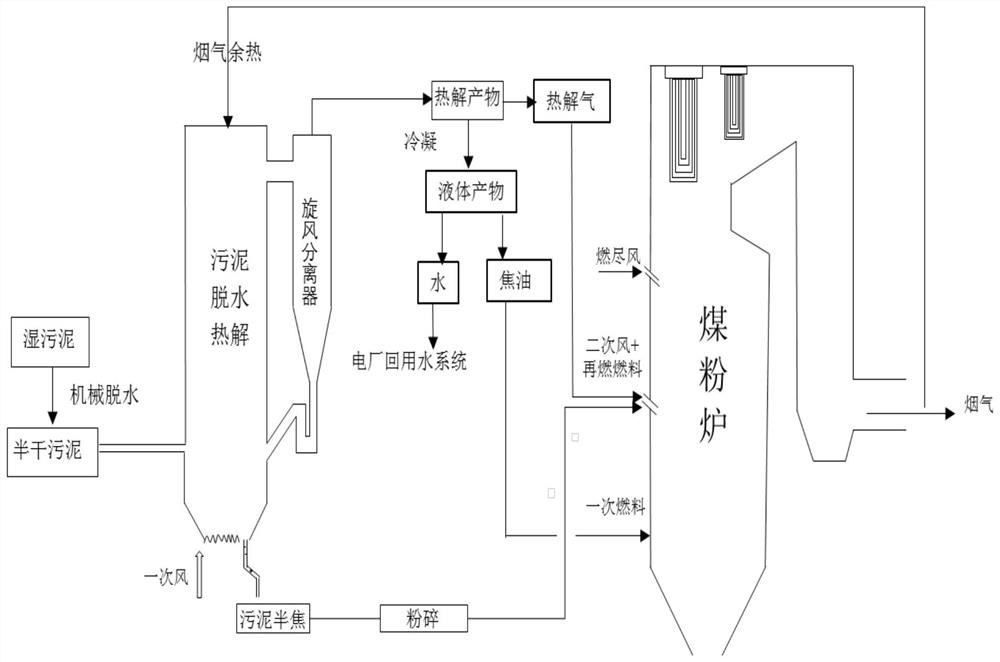

[0043] refer to figure 1 A method for synergistic resource utilization of sludge and coal slime for denitrification of tangential pulverized coal boilers in coal-fired power plants, including the following steps:

[0044] Step 1, mechanically dehydrating municipal domestic sludge or coal slime or a mixture of sludge and coal slime to make semi-dry municipal domestic sludge or coal slime or a mixture of sludge and coal slime;

[0045] Step 2, put the semi-dried urban domestic sludge or coal slime or the mixture of sludge and coal slime after mechanical dehydration in a small fluidized bed boiler with a cyclone separator, and use the flue gas with a flue gas temperature of 500°C from a coal-fired power plant boiler to provide Heat source for simultaneous dehydration and pyrolysis. The cyclone separator recycles and pyrolyzes sludge / coal slime or a mixture of the two coke / semi-coke, and the large solid particles collide with each other in the air flow in the furnace to play a ro...

Embodiment 2

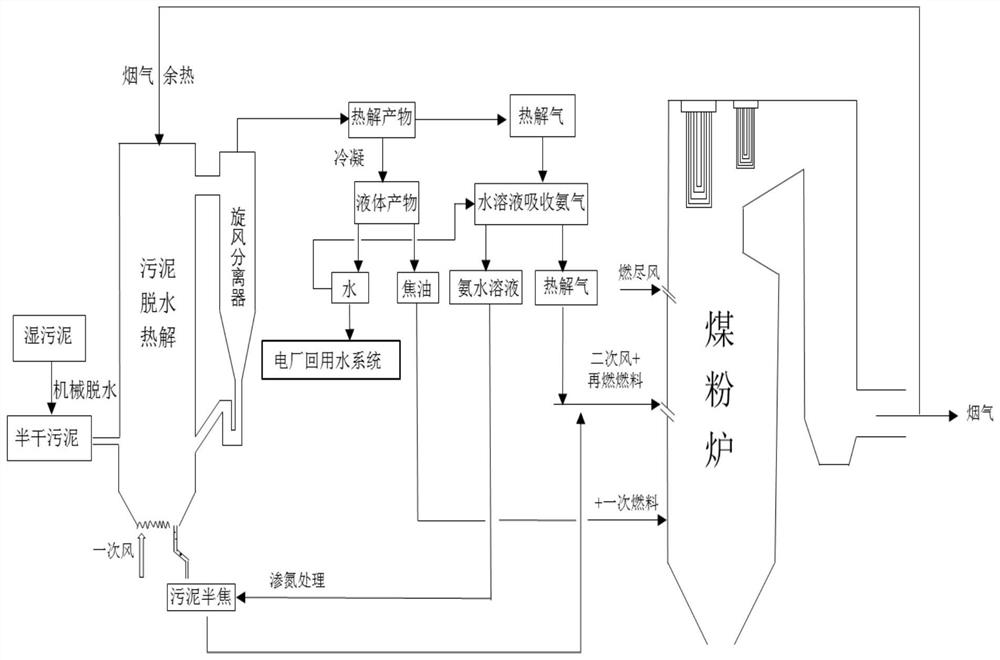

[0050] refer to figure 2 A method for synergistic resource utilization of sludge and coal slime for denitrification of tangential pulverized coal boilers in coal-fired power plants can carry out nitriding modification on the coke surface, including the following steps:

[0051] Step 1, mechanically dehydrating municipal domestic sewage sludge or coal slime or a mixture of sludge and coal slime to produce semi-dry municipal domestic sludge or coal slime or a mixture of sludge and coal slime;

[0052] Step 2, put the semi-dry urban domestic sludge or coal slime or the mixture of sludge and coal slime after mechanical dehydration in a small fluidized bed boiler with a cyclone separator, and use the flue gas of a coal-fired power plant boiler with a flue gas temperature of 600°C to provide Heat source for simultaneous dehydration and pyrolysis. The cyclone separator recycles sludge or coal slime or sludge coal slime mixture coke / semi-coke, and the large solid particles collide w...

Embodiment 3

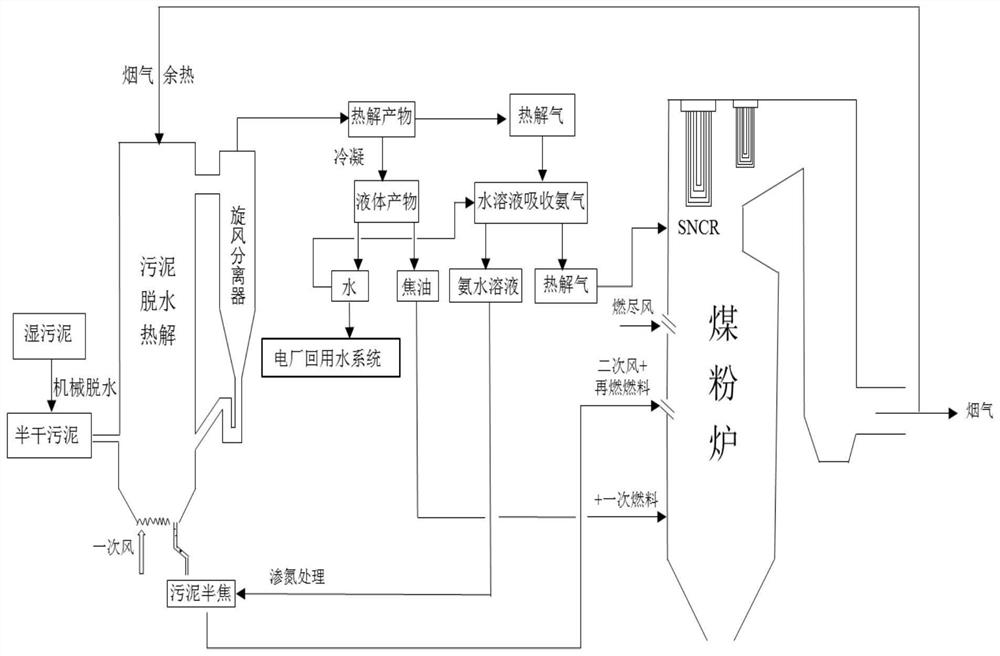

[0057] refer to image 3 The method of synergistic resource utilization of sludge and coal slime for denitrification of tangential pulverized coal boilers in coal-fired power plants can be further combined with SNCR reactions, including the following steps:

[0058] Step 1, mechanically dehydrating municipal domestic sludge or coal slime or a mixture of sludge and coal slime to make semi-dry municipal domestic sludge or coal slime or a mixture of sludge and coal slime;

[0059] Step 2. Put the semi-dried urban domestic sludge or coal slime or the mixture of sludge and coal slime after mechanical dehydration in a small fluidized bed boiler with a cyclone separator, and use the flue gas with a flue gas temperature of 800°C from a coal-fired power plant boiler to provide Heat source for simultaneous dehydration and pyrolysis. The cyclone separator recycles sludge or coal slime or sludge coal slime mixture coke / semi-coke, and the large solid particles collide with each other in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com