Ultrasonic integration desulfurization denitration demercuration method and device thereof

A technology of desulfurization, denitrification, demercury, and ultrasonic is applied in the field of air pollutant control to achieve the effect of saving initial investment costs and operation and maintenance costs, and has a good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The working principle and working process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

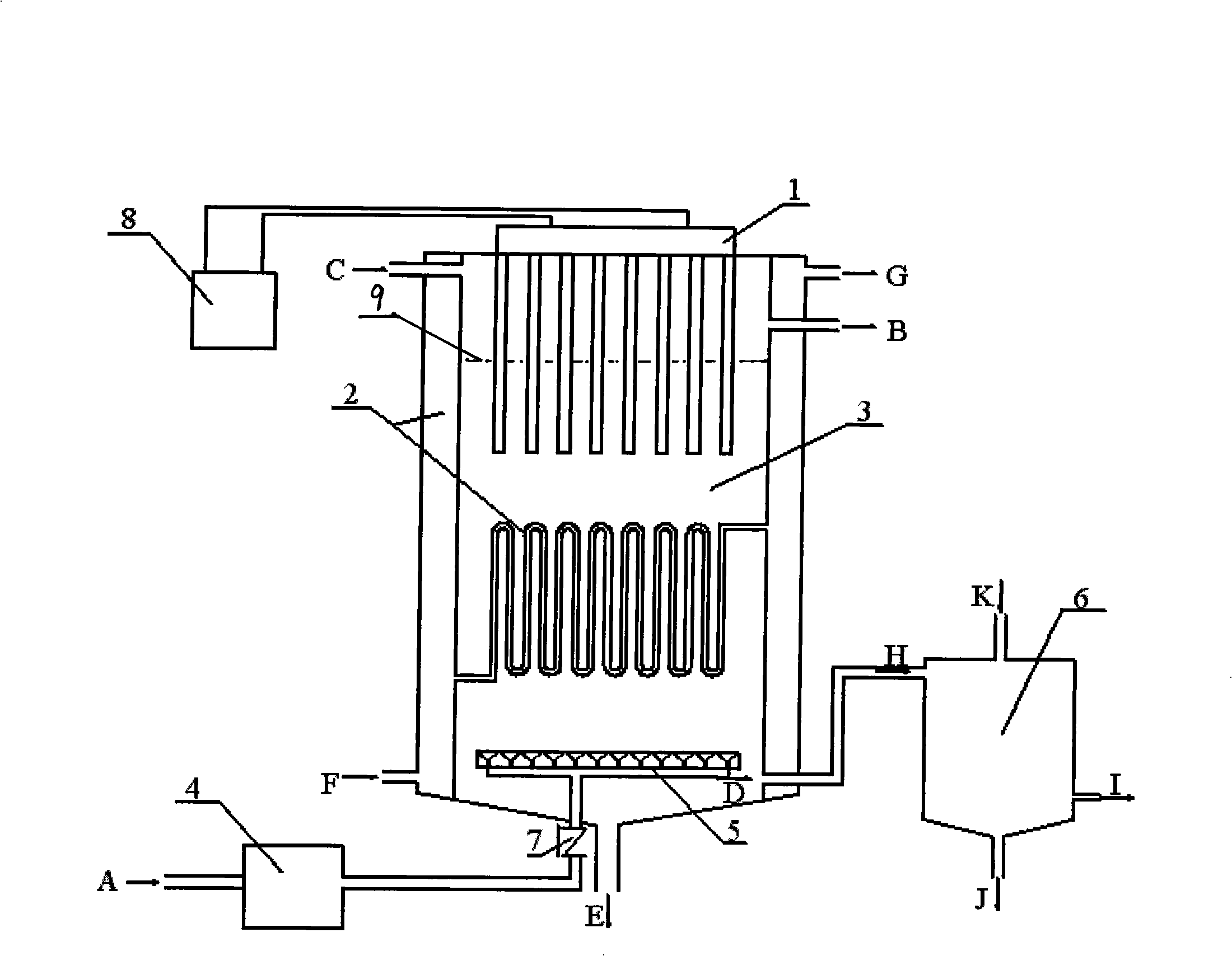

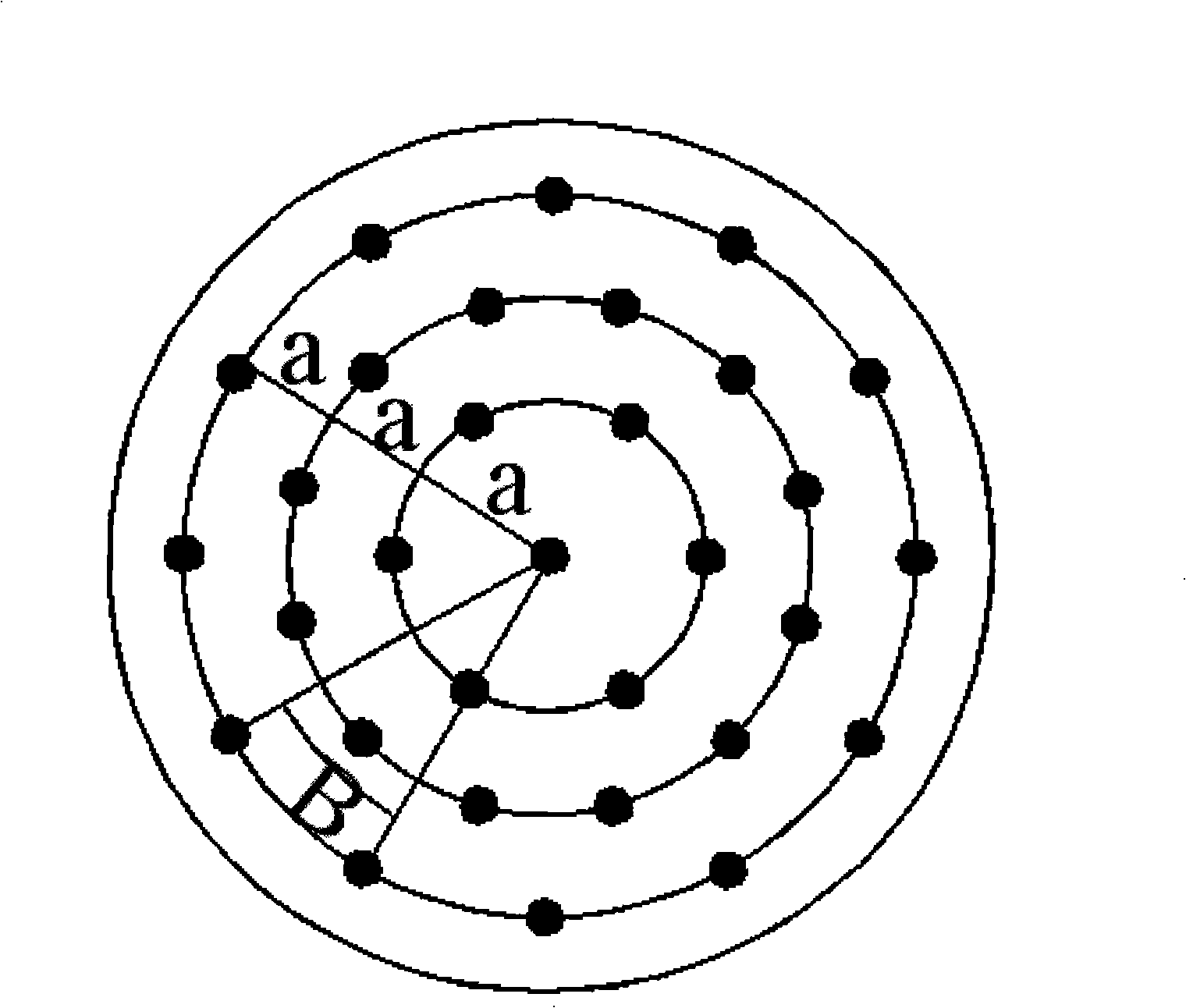

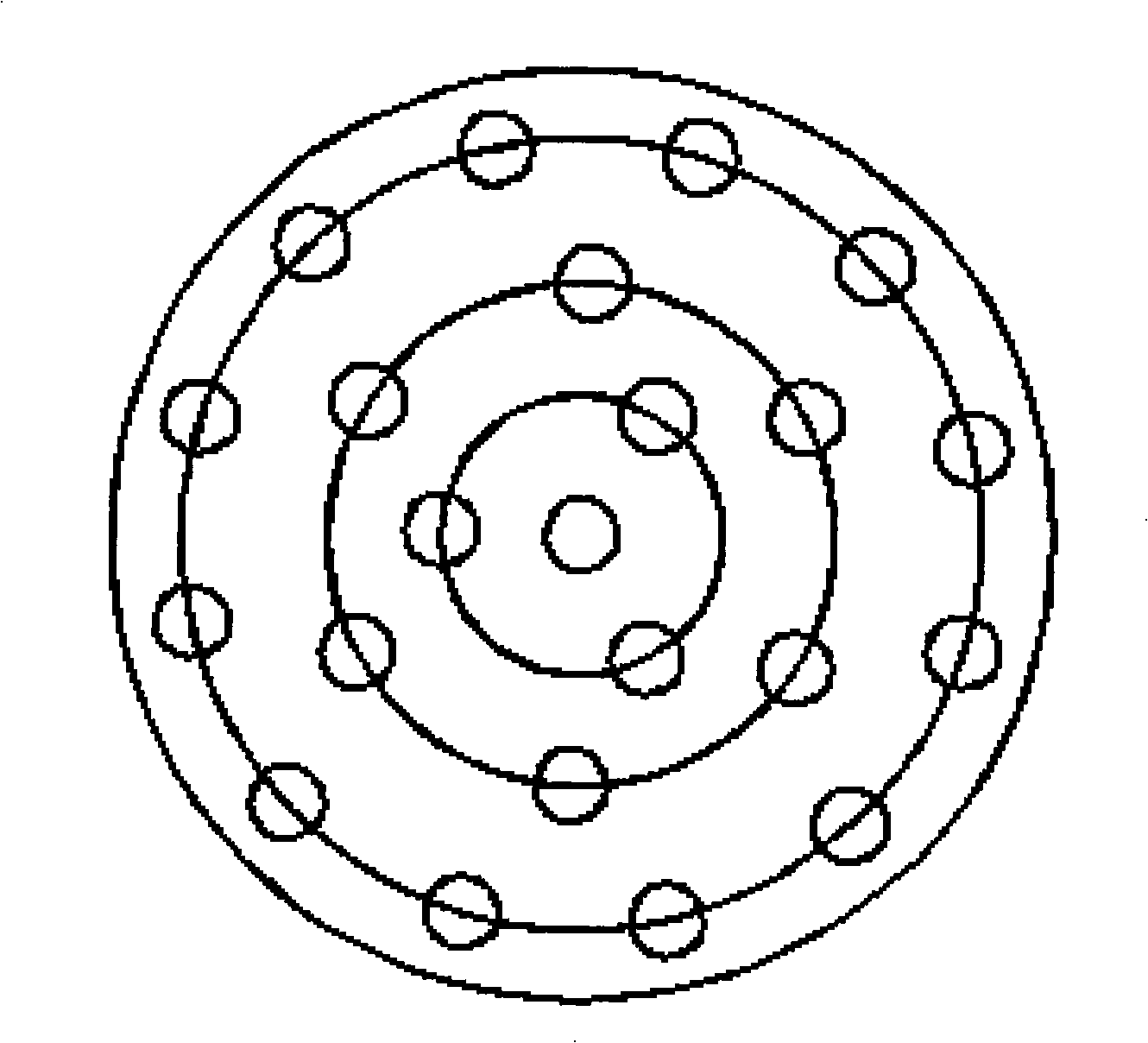

[0049] see figure 1 , the ultrasonic integrated desulfurization, denitrification and mercury removal device of the present invention is mainly composed of an ultrasonic generator 8, an ultrasonic transmitter 1, a cooling water system (including a cooling water jacket and a cooling coil) 2, a bubbling bed reactor 3, and an electrostatic precipitator 4 , flue gas diffuser 5, separation tower 6 and check valve 7; the ultrasonic transmitter 1 is placed in the reaction liquid in the bubble bed reactor 3, and the inside and outside of the bubble bed reactor 3 is provided with a cooling water system 2, The cooling water outlet (G) and the cooling water inlet (F) are respectively located at the upper and lower parts of the bubbling bed reactor 3, and the flue gas A treated by the first-stage dust collector passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com