A kind of method that takes dichloroethane as raw material to produce trichloroethylene and tetrachloroethylene

A technology of dichloroethane and trichloroethylene, applied in the chemical industry, can solve the problems of high safety technical requirements, high realization difficulty, high technical difficulty and the like, and achieves the effects of simple process, easy control, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

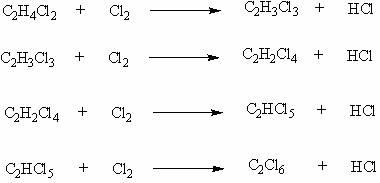

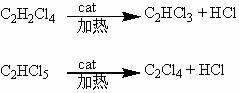

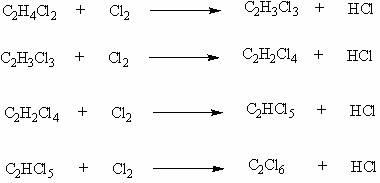

Method used

Image

Examples

Embodiment 1

[0024] Step (1). Vaporize dichloroethane, turn on the ultraviolet lamp in the reaction tower, then pass dichloroethane gas and chlorine gas into the reaction tower according to the molar ratio of 1:2, and control the reaction temperature to 160°C. Generate a mixture of dichloroethane / trichloroethane / tetrachloroethane / pentachloroethane / hexachloroethane (the composition of the mixture is 2.6% of dichloroethane, 30.8% of trichloroethane, 30.8% of tetrachloroethane Ethane 45.9%, pentachloroethane 18.8%, hexachloroethane 1.3%, other impurities 0.6%) and hydrogen chloride gas; dichloroethane / trichloroethane / tetrachloroethane / pentachloroethane / hexachloro The ethane mixture is condensed and enters the collector, and the hydrogen chloride gas is absorbed by water.

[0025] Step (2). The mixture of dichloroethane / trichloroethane / tetrachloroethane / pentachloroethane / hexachloroethane is moved into the rectification tower by the collector and rectified at 80~162°C; the top temperature is at...

Embodiment 2

[0030]Step (1). Evaporate dichloroethane, turn on the ultraviolet lamp in the reaction tower, then pass dichloroethane gas and chlorine gas into the reaction tower according to the molar ratio of 1:2.7, and simultaneously feed water vapor and feed The weight of water vapor is 0.05 times that of dichloroethane. Control the reaction temperature at 140°C to generate a mixture of dichloroethane / trichloroethane / tetrachloroethane / pentachloroethane / hexachloroethane (the composition of the mixture is 0.9% dichloroethane, trichloroethane ethane 8.8%, tetrachloroethane 38.3%, pentachloroethane 48.8%, hexachloroethane 2.8%, other impurities 0.4%) and hydrogen chloride gas; dichloroethane / trichloroethane / tetrachloroethane / The pentachloroethane / hexachloroethane mixture is condensed and enters the collector, and the hydrogen chloride gas is absorbed by water.

[0031] Step (2). The mixture of dichloroethane / trichloroethane / tetrachloroethane / pentachloroethane / hexachloroethane is moved into...

Embodiment 3

[0036] Step (1). Vaporize the dichloroethane, turn on the ultraviolet lamp in the reaction tower, then pass the dichloroethane gas and chlorine gas into the reaction tower according to the molar ratio of 1:3.2, and simultaneously pass into water vapor, pass into The weight of water vapor is 0.5 times that of dichloroethane. Control the reaction temperature at 100°C to generate a mixture of dichloroethane / trichloroethane / tetrachloroethane / pentachloroethane / hexachloroethane (the composition of the mixture is 0.7% dichloroethane, trichloroethane ethane 4.8%, tetrachloroethane 44.3%, pentachloroethane 49.2%, hexachloroethane 0.4%, other impurities 0.6%) and hydrogen chloride gas; dichloroethane / trichloroethane / tetrachloroethane / The pentachloroethane / hexachloroethane mixture is condensed and enters the collector, and the hydrogen chloride gas is absorbed by water.

[0037] Step (2). The mixture of dichloroethane / trichloroethane / tetrachloroethane / pentachloroethane / hexachloroethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com