Method for intensively removing hexachloro-cyclohexane soprocide and dichlorodiphenyl trichloroethane in soil by zero-valent iron

A technology of zero-valent iron and BHC, which is applied in the field of zero-valent iron to strengthen the removal of BHC and DDT in soil, can solve the problems of unfavorable soil reductive dechlorination reaction, limited activity of ordinary iron powder, and difficulty in rapid degradation, etc., to achieve Fast and efficient degradation, easy operation and cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

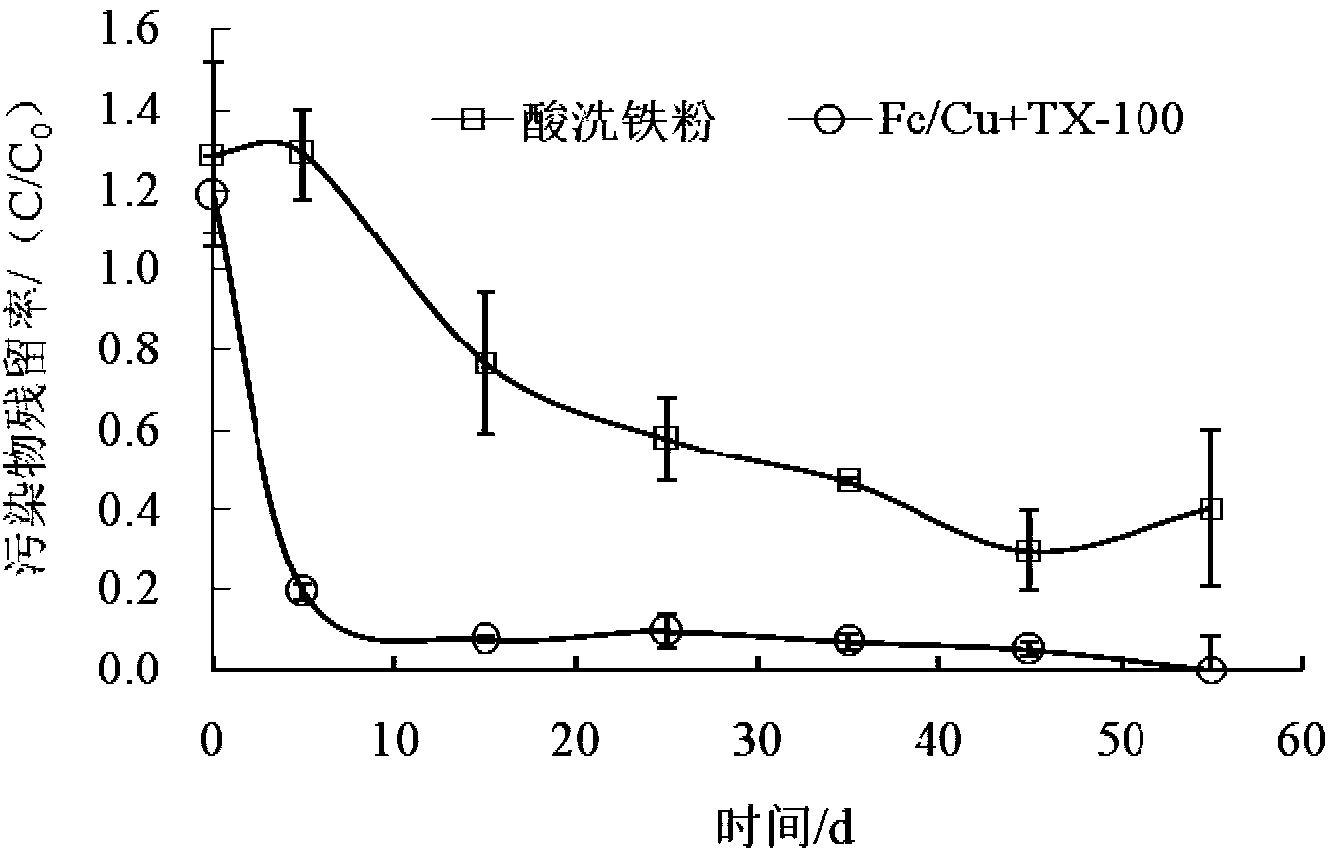

[0031] Embodiment 1: to the processing of 666 polluted soil

[0032] In this example, the method proposed by the invention is used to treat the H66-contaminated soil in an abandoned pesticide factory in Jiangsu. The initial concentrations of α-HCH and γ-HCH in soil were 3.6mg / kg and 10.1mg / kg respectively. Weigh 15 g of commercially available 100-mesh reduced iron powder, pickle it with 0.5 mol / L sulfuric acid, immerse the iron powder in 150 mL of copper chloride solution with a Cu concentration of 2 g / L, and mix thoroughly to obtain Fe / Cu bimetallic material. Weigh 300g of HCH-contaminated soil into a 1L plastic bottle, add the prepared 15g of Fe / Cu bimetal, and stir to mix. Add 50ml of TX-100 with a concentration of 10mmol / L (mass concentration: 0.647%), and add 40ml of water. The final soil moisture content is about 25%, stir evenly. The soil pH was adjusted to 4.5 with glacial acetic acid. Cover and seal, and cultivate in a constant temperature incubator at 25°C. Sam...

Embodiment 2

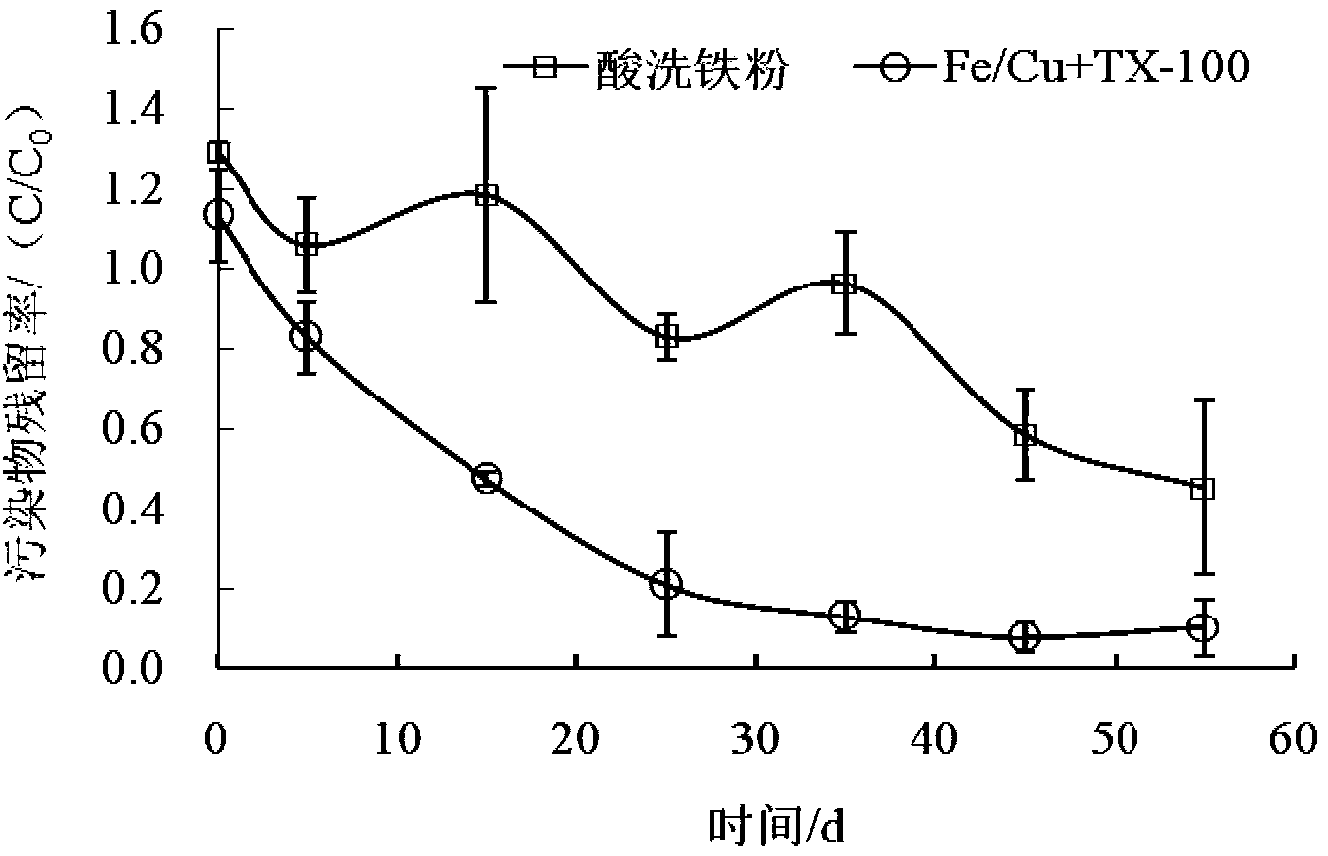

[0033] Embodiment 2; To the processing of DDT polluted soil

[0034]This example uses the method proposed by the invention to treat DDT-contaminated soil in an abandoned pesticide factory site in Jiangsu. The initial concentration of the main target pollutant p,p'-DDT in the soil was 19.0mg / kg. Weigh 15 g of commercially available 100-mesh reduced iron powder, pickle it with 0.5 mol / L sulfuric acid, immerse the iron powder in 150 mL of copper chloride solution with a Cu concentration of 2 g / L, and mix thoroughly to obtain Fe / Cu bimetallic material. Weigh 300 DDT-contaminated soil into a 1L plastic bottle, add the prepared 15g Fe / Cu bimetal, stir and mix. Add 50ml of TX-100 with a concentration of 10mmol / L (mass concentration: 0.647%), and add 40ml of water. The final soil moisture content is about 25%, stir evenly. The soil pH was adjusted to 4.5 with glacial acetic acid. Cover and seal, and cultivate in a constant temperature incubator at 25°C. Sampling was carried out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com