Synergistic antifouling material based on microstructures and antifouling active substances and preparation method thereof

A technology of active substances and microstructures, applied in botany equipment and methods, chemical instruments and methods, animal repellents, etc., can solve the problem of difficulty in achieving the concentration of inhibiting fouling organisms, loss of antifouling effect, and antifouling agent change. Small and other problems, achieve metal corrosion protection and good effect of inhibiting bacterial growth, prolong antifouling period and prevent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

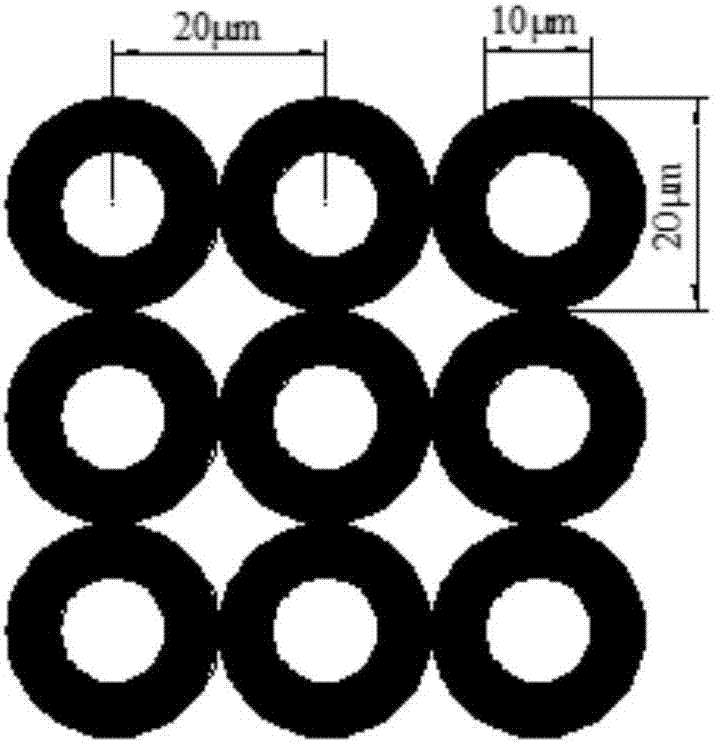

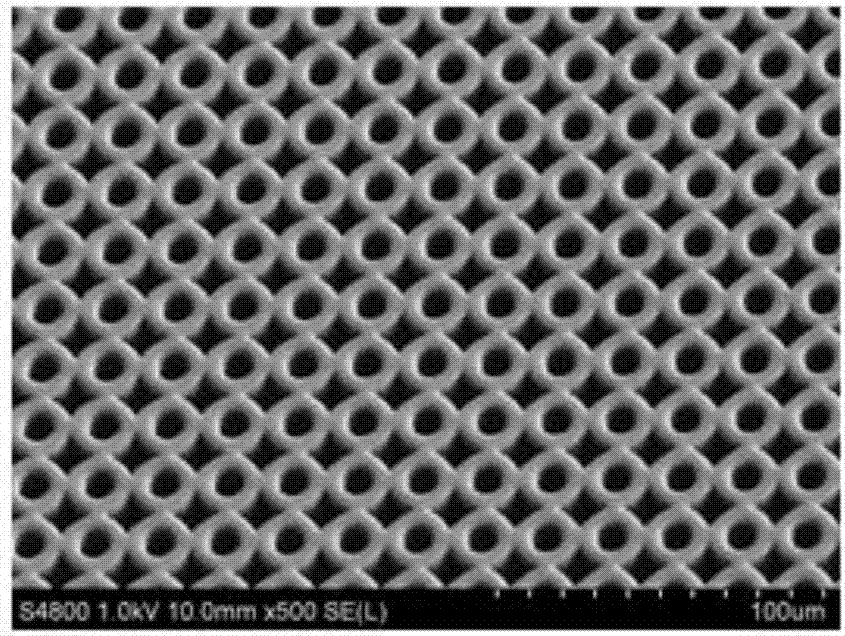

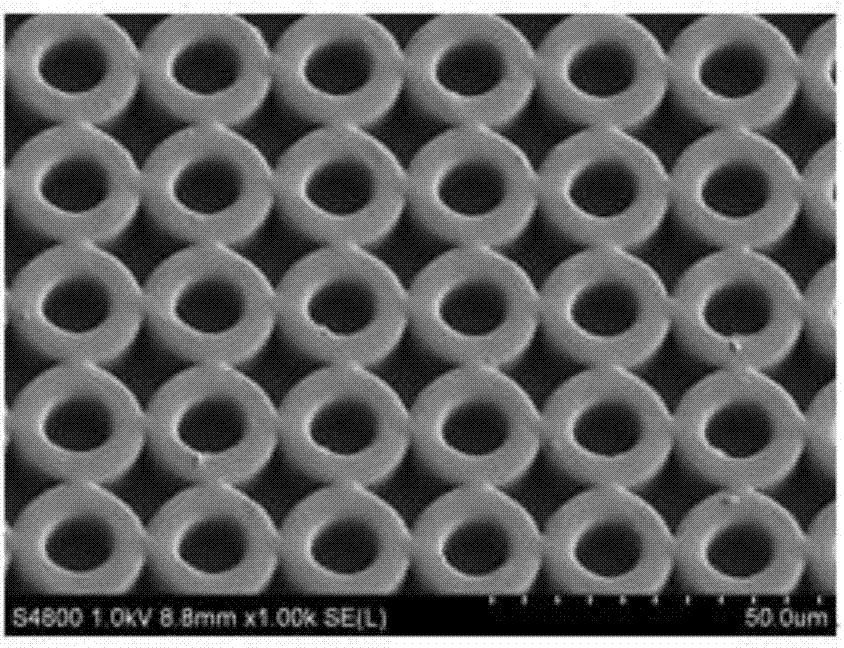

[0019] The microstructure and antifouling active material synergistic antifouling material involved in this embodiment is composed of a matrix arrangement formed by several polydimethylsiloxane organosilicon microstructure basic units in a circular well-shape structure. The outer diameter of the basic unit of the microstructure is 20 microns, the inner diameter of the basic unit of the microstructure is 10 microns, the distance between the basic units of the microstructure is 20 microns, the depth of the basic unit of the microstructure is 20 microns, and the inner lower layer of the basic unit of the microstructure is filled with sulfonamide anti-corrosion Stain agent, the inner upper layer of the microstructure basic unit is filled with polydimethylsiloxane silicone oil.

[0020]The process of the preparation method of the microstructure and antifouling active substance synergistic antifouling material involved in this embodiment includes three steps: preparation of microstru...

Embodiment 2

[0026] The microstructure and antifouling active material synergistic antifouling material involved in this embodiment is composed of a matrix arrangement formed by several polydimethylsiloxane organosilicon microstructure basic units in a circular well-shape structure. The outer diameter of the microstructure basic unit is 20 microns, the inner diameter of the microstructure basic unit is 10 microns, the pitch of the microstructure basic unit is 20 microns, the depth of the microstructure basic unit is 20 microns, and the inner lower layer of the microstructure basic unit is filled with isothiazolinone Antifouling agent, the inner upper layer of the microstructured basic unit is filled with perfluoropolyether.

[0027] The process of the preparation method of the microstructure and antifouling active substance synergistic antifouling material involved in this embodiment includes three steps: preparation of microstructure, preparation of liquid antifouling active substance and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com