A biomimetic textured material with anti-algae adhesion performance and preparation method thereof

A biomimetic texture and adhesion technology, applied in biocide-containing paints, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems such as accumulation, increased ship sailing resistance, corrosion damage, etc. The effect of reducing the contact area, reducing the number of attachment sites, and not easy to attach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

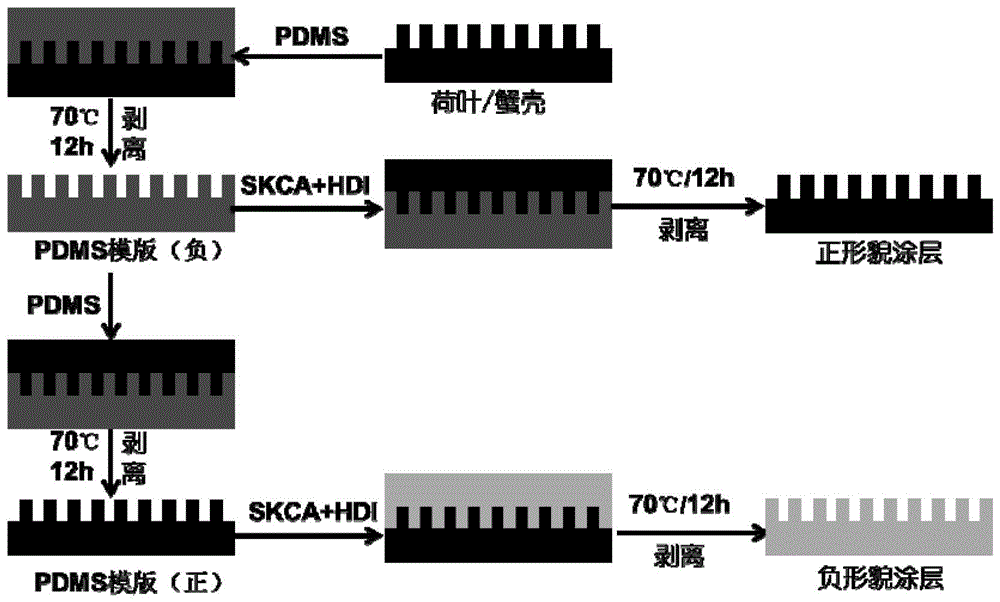

[0034] Example 1: Preparation of silicone acrylate antifouling coating with positive morphology microstructure imitating crab shell

[0035] according to figure 1 The process shown prepares a textured coating with a positive morphology of crab shells: wash the surface of crab shells with deionized water, and dry them with a weak nitrogen flow. Then prepare the silicone elastomer template; the preparation process is as follows: fully mix Dow Corning SYLGARD184 polydimethylsiloxane (PDMS) and its supporting crosslinking agent at a mass ratio of 10:1, first cure at room temperature for 2 hours, and Remove the air bubbles in the mixed solution; then pour the mixed solution on the surface of the crab shell, and then cure it at 70°C for 12 hours; finally, peel the cured PDMS from the crab shell to obtain a silicone elastic material with a negative surface morphology of the crab shell. body template.

[0036]The process of preparing silicone-modified acrylic polyurethane coating is...

Embodiment 2

[0038] Example 2: Preparation of silicone acrylate antifouling coating material with negative morphology of imitation crab shell

[0039] according to figure 1 The process shown is to prepare a textured coating with a negative morphology of crab shells, where the curing temperature and time can be adjusted appropriately: wash the surface of crab shells with deionized water, and dry them with a weak nitrogen flow. Then prepare the silicone elastomer template; the preparation process is as follows: fully mix Dow Corning SYLGARD184 polydimethylsiloxane (PDMS) and its supporting crosslinking agent at a mass ratio of 10:1, first cure at room temperature for 2 hours, and Remove the air bubbles in the mixed solution; then pour the mixed solution on the surface of the crab shell, and then cure it at 50°C for 15 hours; finally, peel the cured PDMS from the crab shell to obtain a silicone elastic material with a negative surface morphology of the crab shell. body template. The treated...

Embodiment 3

[0042] Example 3: Preparation of organosilicon acrylate antifouling coating material with positive morphology imitating lotus leaf

[0043] according to figure 1 The process shown is to prepare a textured coating with the positive shape of lotus leaves, in which the curing temperature and time can be adjusted appropriately: wash the surface of lotus leaves with deionized water, and dry them with a weak nitrogen flow. Then prepare the PDMS template; the preparation process is as follows: fully mix Dow Corning SYLGARD184 polydimethylsiloxane (PDMS) and its supporting crosslinking agent at a mass ratio of 10:1, first cure at room temperature for 2 hours, and remove the mixed solution Then pour the mixture on the surface of the lotus leaf, and then cure it at 150°C for 8 hours; finally, the cured silicone elastomer is peeled off from the lotus leaf to obtain a silicone elastomer with a negative surface morphology of the lotus leaf. body template.

[0044] The process of preparin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com