Sinking rotary shaft boring machine

A roadheader and rotary technology, which is applied in the direction of shaft equipment, sinking, drilling equipment, etc., can solve the problems of low safety of construction personnel, low degree of mechanization, and slow speed of excavating soil, and achieve low repeated crushing rate and automation High degree of effect with low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

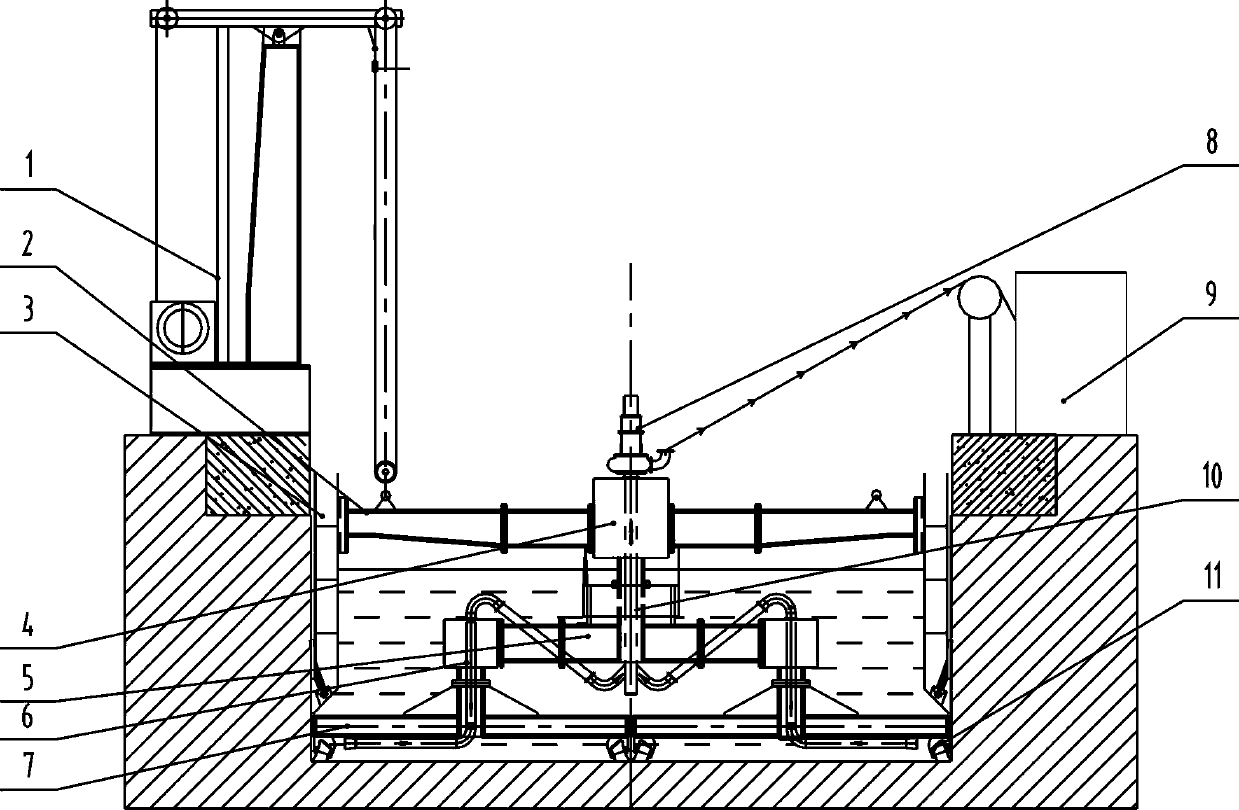

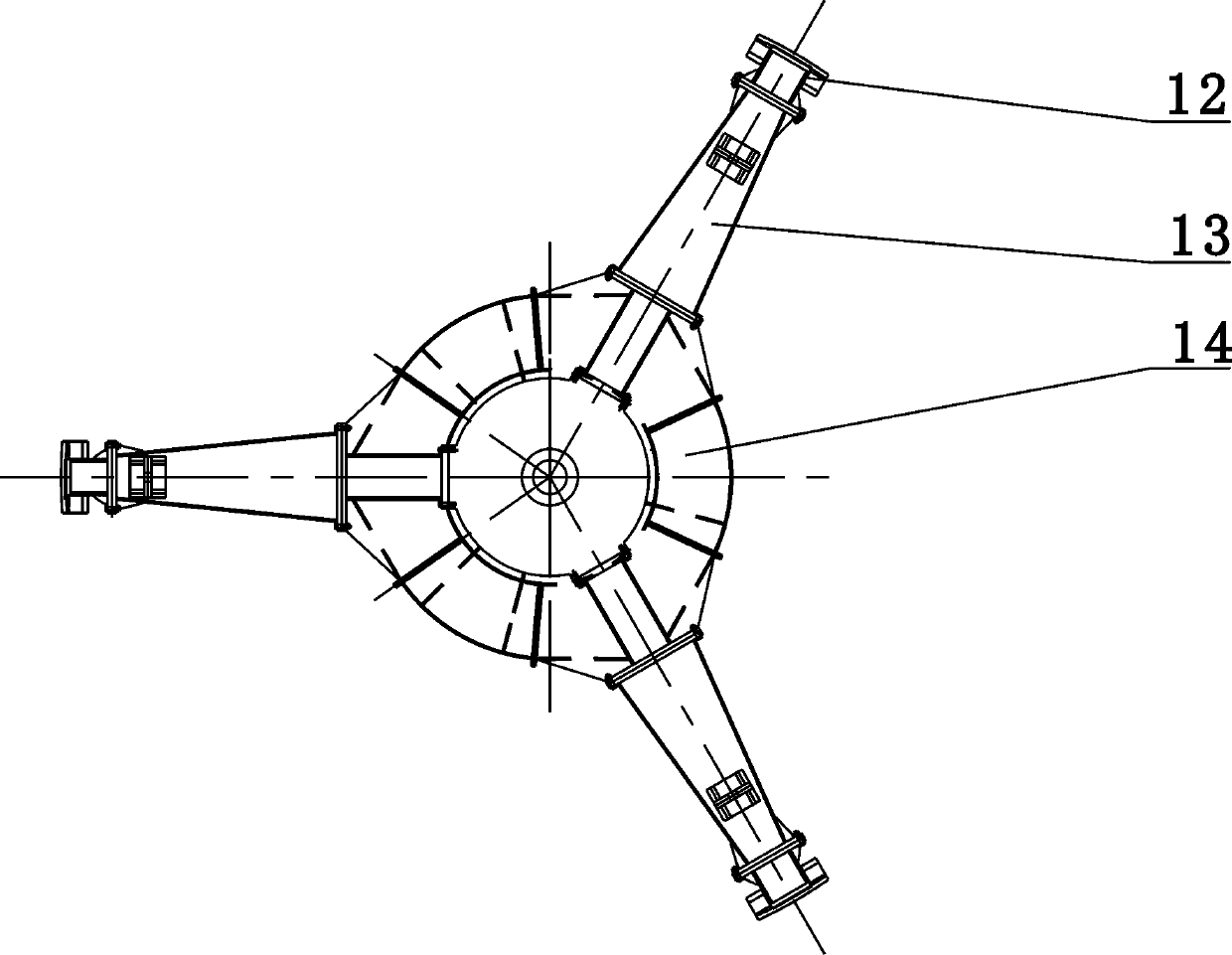

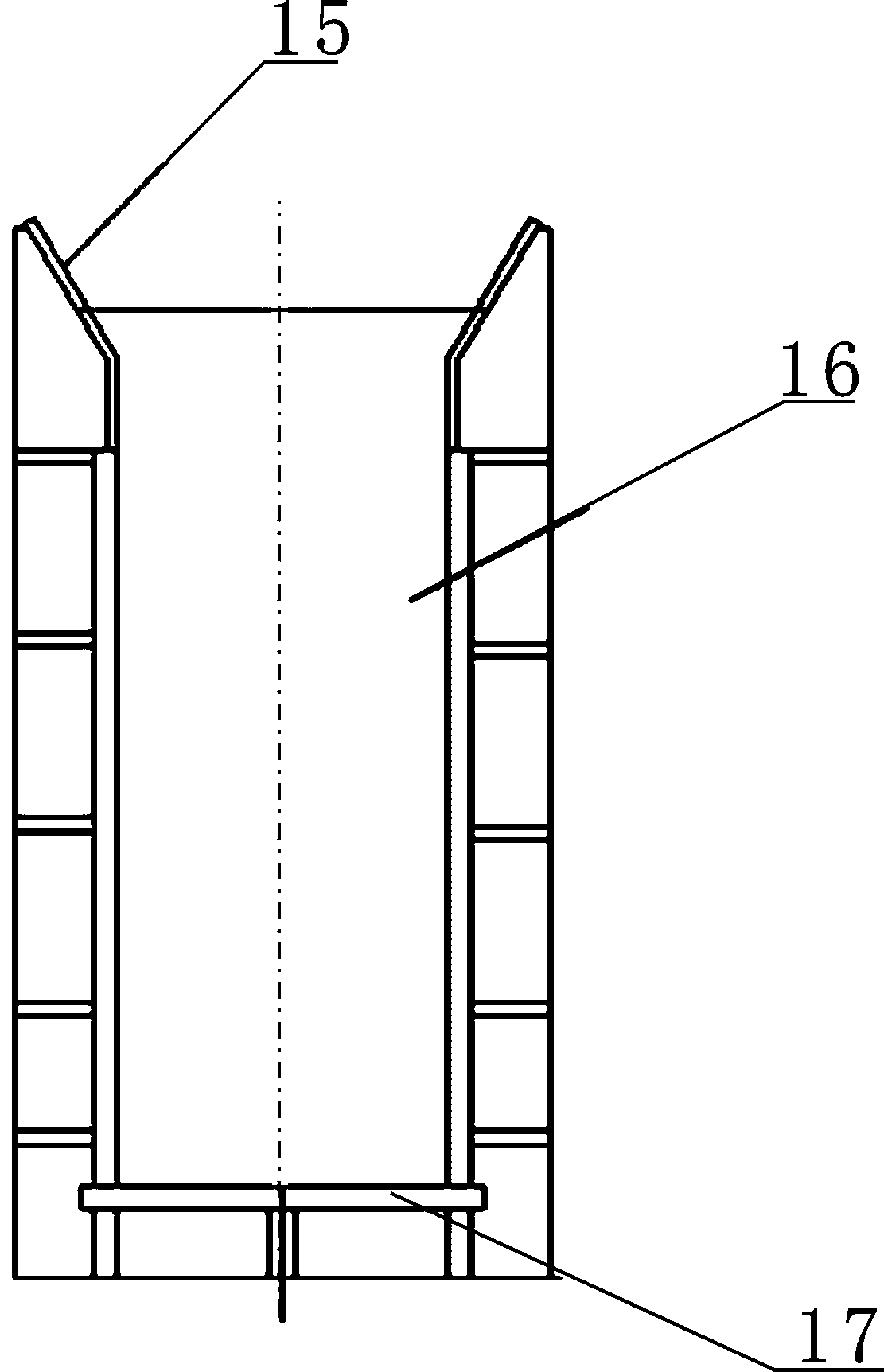

[0046] combined with Figure 1-19 It includes the excavation mechanism and the power lifting mechanism installed on the ground for lifting and lowering the excavation mechanism, the slurry separation mechanism for lifting and discharging the mud generated in the vertical shaft after the excavation mechanism breaks the soil, and for controlling the operation of the above-mentioned mechanisms The operation control system; the excavation mechanism includes the excavation frame 2, the drilling arm 5, the main driving device 4 that drives the drilling arm 5 to rotate, the drilling tool and the auxiliary driving device 6 that drives the drilling tool to rotate, and the main driving device 4 includes the first outer box body, and the main drive motor 43 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com