A preparation method of anti-fouling material with needle-shaped filler oriented arrangement

A needle-shaped filler and directional arrangement technology, which is applied in antifouling/underwater coatings, rosin coatings, paints containing biocides, etc., can solve marine fouling organisms that are not easy to attach to the surface, antifouling, environmental pollution, slime fouling, etc. problems, achieve good static antifouling performance and environmental protection performance, simple and easy preparation method, and reduce the effect of attachment sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

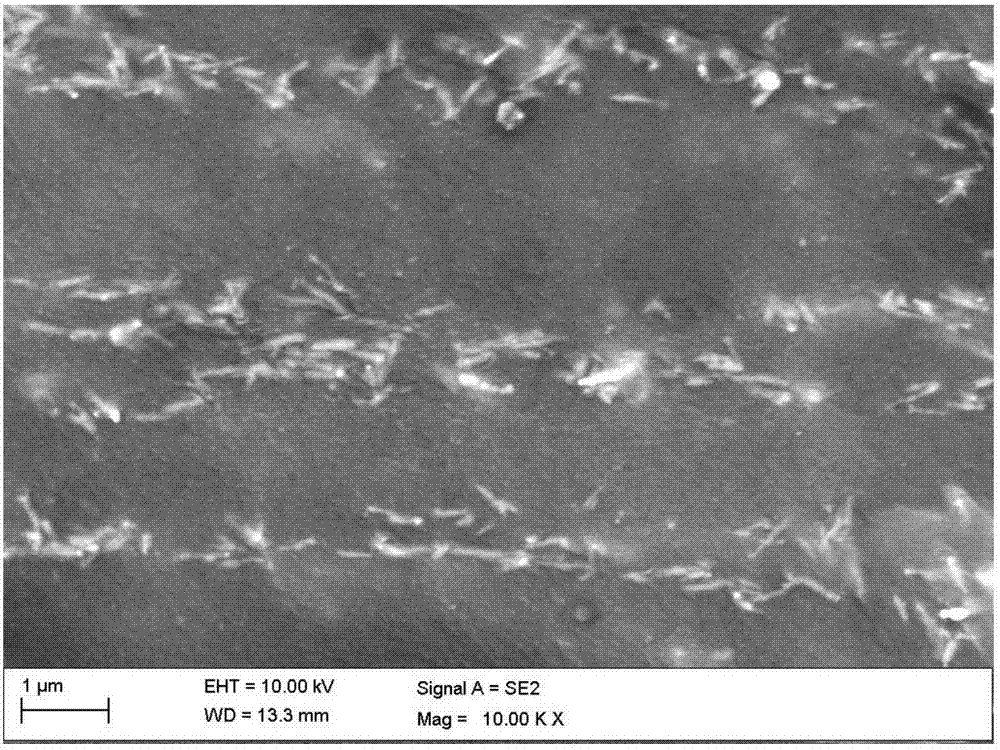

[0015] The quality components of the antifouling material prepared in this example with directional arrangement of needle-like fillers include 30 parts of polyacrylic acid zinc resin, 10 parts of rosin, 20 parts of cuprous oxide, 3 parts of zinc oxide, 1 part of carbon black, acicular Cr 2 o 3 5 parts, 1 part of silicone oil, 0.5 parts of silicon dioxide and 10 parts of xylene.

[0016] The preparation process of the antifouling material with directional arrangement of needle-like fillers involved in this embodiment is as follows: add zinc polyacrylate resin, rosin, cuprous oxide, zinc oxide, carbon black, silicone oil and xylene to the container in sequence according to the set mass parts , after stirring at high speed for 2 hours, add silicon dioxide and acicular Cr to the container in sequence according to the set mass parts 2 o 3 and stirred at high speed for 1 hour to obtain an antifouling coating. After coating the antifouling coating on the surface of the substrate, ...

Embodiment 2

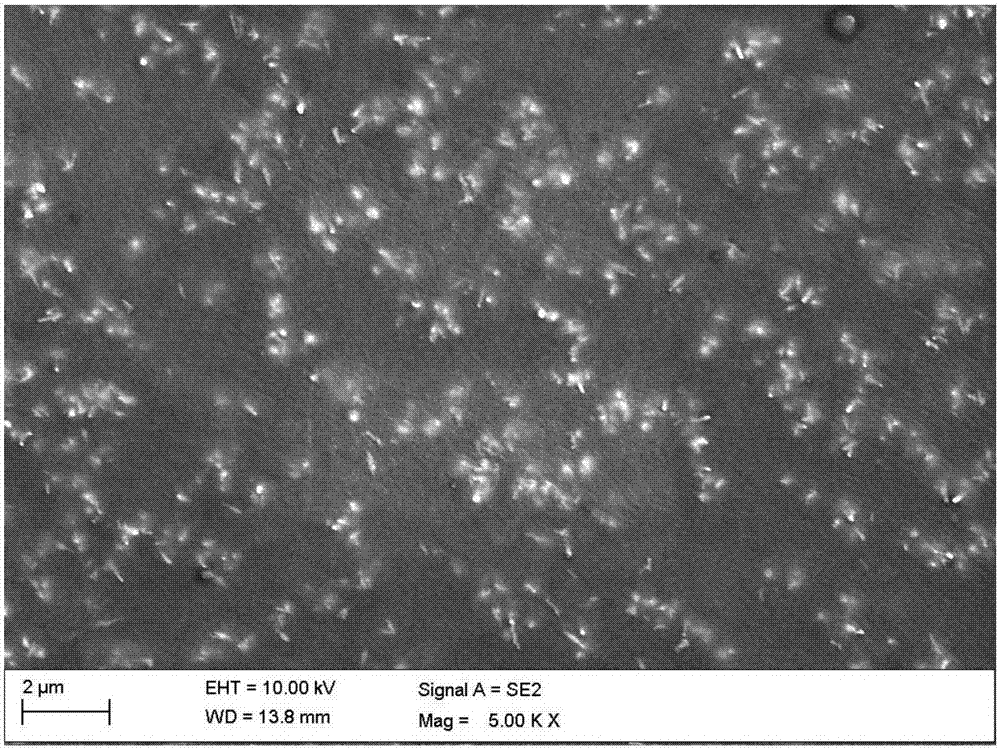

[0018] The quality components of the antifouling material prepared in this example with oriented arrangement of needle-like fillers include 50 parts of polyacrylic silane resin, 15 parts of rosin, 15 parts of cuprous oxide, 4,5-dichloro-2-n-octyl-4 - 2 parts of isothiazolin-3-one, 3 parts of iron red, needle-shaped γ-Fe 3 o 4 0.5 parts, 5 parts of chlorinated paraffin, 1 part of polyacrylamide and 15 parts of dimethyl carbonate.

[0019] The preparation process of the antifouling material with directional arrangement of needle-like fillers involved in this embodiment is as follows: add polyacrylic silane resin, rosin, cuprous oxide, 4,5-dichloro-2- n-octyl-4-isothiazolin-3-one, iron red, chlorinated paraffin and dimethyl carbonate, after ball milling for 24 hours, add polyacrylamide and needle-shaped γ-Fe 3 o 4 and stirring at a high speed for 2 hours to obtain an antifouling coating. The antifouling coating is coated on the surface of the substrate and cured in a uniform ...

Embodiment 3

[0021] The quality components of the antifouling material prepared in this example with oriented arrangement of needle-like fillers include 10 parts of polyacrylic acid copper resin, 5 parts of rosin, 10 parts of cuprous oxide, 2 parts of copper pyrithione, N-cyclopropyl-N' -(1,1-Dimethylethyl)-6-(methylthio)-1,3,5-triazine-2,4-diamine 3 parts, toluidine red 5 parts, needle-shaped nickel powder 10 parts, 0.5 parts of stearic acid, 0.2 parts of silicon dioxide, 2 parts of xylene and 1 part of n-butanol.

[0022] The preparation process of the anti-fouling material with needle-like fillers oriented arrangement in this embodiment is as follows: add polyacrylic acid copper resin, rosin, cuprous oxide, copper pyrithione, N-cyclopropyl -N'-(1,1-dimethylethyl)-6-(methylthio)-1,3,5-triazine-2,4-diamine, toluidine red, stearic acid, di Toluene and n-butanol, after ball milling for 12 hours, add silicon dioxide and needle-shaped nickel powder to the container in sequence according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com