Environment-friendly antifouling paint as well as preparation method and application thereof

An antifouling coating, an environmentally friendly technology, applied in the field of coatings, can solve problems affecting human health and ecological safety, high VOC content, organic solvent release, etc., achieve excellent anti-biofouling properties, strong mechanical properties of the paint film, Good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

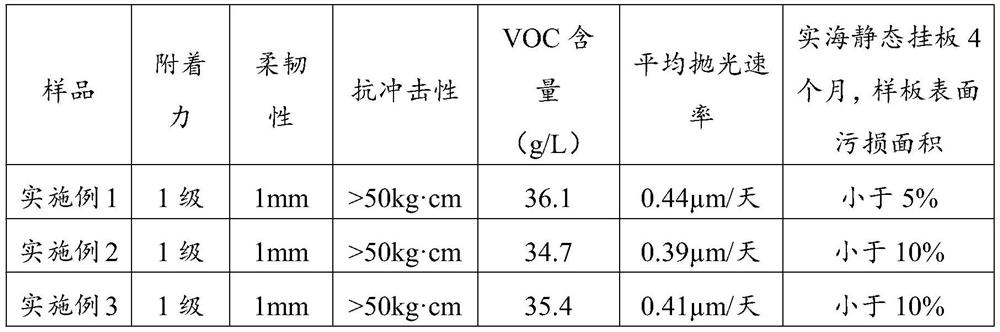

Examples

preparation example Construction

[0039] The raw materials for the preparation of the anion-cation polymer antifouling agent include anion-type polymerizable monomers, cationic-type polymerizable monomers, azo initiators and organic solvents.

[0040] The anion-cation polymer modified emulsion will be described in detail below first. In terms of mass percentage, the environment-friendly antifouling paint comprises 25-50% of anion-cation polymer modified emulsion, preferably 32-40%. In the present invention, based on the mass of the anionic and cationic polymer modified emulsion as 100%, the anionic and cationic polymer modified emulsion includes the following mass percentages of preparation raw materials: anionic polymerizable monomer 1-3%, Cationic polymerizable monomer 1-3%, triisopropyl acrylate silicon ester 10-20%, acrylate monomer 25-40%, acrylic acid 0.5-1.5%, emulsifier 1-2%, inorganic peroxide 0.3-0.6% initiator, 0.05-0.1% sodium bicarbonate, 0.3-0.5% pH regulator, and water as the balance; more pref...

Embodiment 1

[0089] Preparation of cationic polymer modified emulsion:

[0090] Weigh 6g of 3-sulfonic acid propyl potassium salt, 6g of 2-(methacryloyloxy)ethyltrimethylammonium chloride, 46g of silicon triisopropylacrylate, 10g of butyl acrylate, 11g of acrylic acid Ethyl ester, 50g methyl methacrylate, 17g isobornyl methacrylate and 2.5g acrylic acid, mix well at 25°C, add 3g non-ionic emulsifier OP-10, 1.5g reactive emulsifier Adico SR- 10 and 110g of deionized water were stirred and emulsified at a speed of 600r / min for 30min to obtain a monomer emulsion;

[0091] Weighing 1.4g ammonium persulfate was dissolved in 20g deionized water to obtain a 6.5% initiator aqueous solution with a mass concentration;

[0092] Take by weighing 0.2g sodium bicarbonate, 20g deionized water, the described monomer emulsion of 75g and the described initiator aqueous solution of 3.2g, stir 0.5h with the speed of 600r / min under room temperature condition, afterwards under stirring condition with 5 The he...

Embodiment 2

[0098] The preparation of anion-cation polymer modified emulsion and anion-cation polymer antifouling agent is the same as that in Example 1.

[0099] Preparation of environmentally friendly antifouling coatings:

[0100] Mix 30g deionized water, 0.21g water-based thickener (0.2g DeuRheo WT-05A and 0.01g hydroxyethyl cellulose), 0.4g water-based wetting and dispersing agent AC 8892, 0.2g water-based leveling agent DC57 and 0.4g water-based Stir and mix the defoamer DAPROAP7010 in the dispersing tank evenly, add 11g of anionic and cationic polymer antifouling agent, 3.5g of diuron, 3.3g of Zineb and 10.5g of pigments and fillers (2.5g each of talc powder, zinc oxide and mica powder , organic bentonite 3g), disperse at a high speed for 30min under the condition of 800r / min and then grind until the fineness is less than 40μm, add 39.5g of anionic and cationic polymer modified emulsion, 0.4g of ethylene glycol butyl ether and 0.6g of alcohol ester ten 2. Stir and disperse for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com