Copper-free and environment-friendly self-polishing ocean antifouling paint

A self-polishing, matrix resin technology, applied in anti-fouling/underwater coatings, anti-corrosion coatings, coatings, etc., can solve problems such as entering the food chain, destroying marine ecological balance, and marine environmental hazards, so as to reduce emissions and save heavy metals resources, and the effect of prolonging the antifouling period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

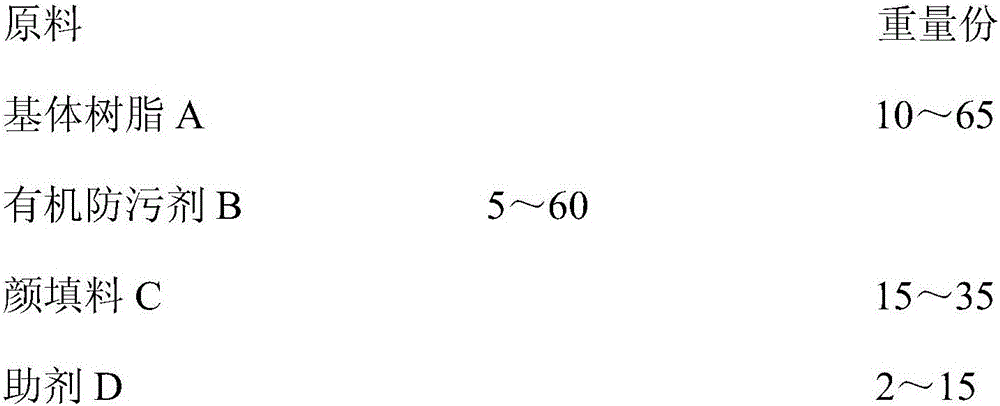

Method used

Image

Examples

Embodiment 1

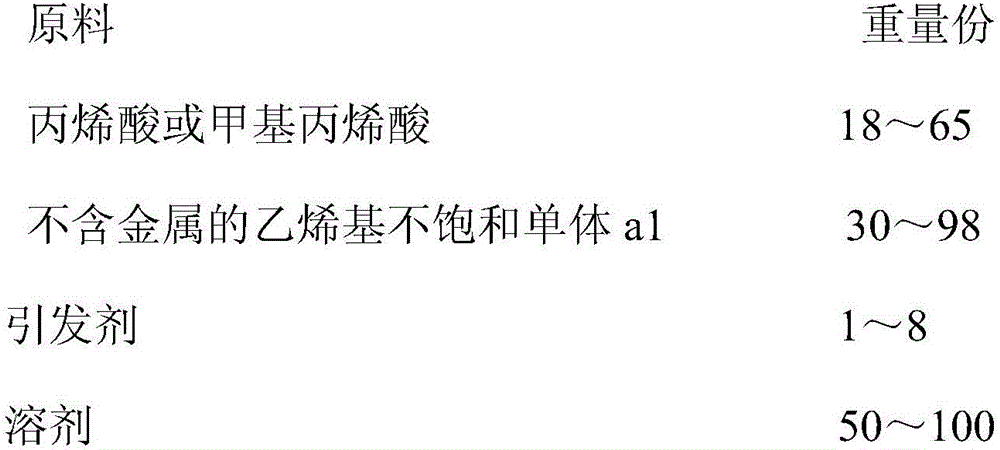

[0036] 1a. Preparation of Acrylic Prepolymer

[0037] Add 25 parts of propylene glycol methyl ether, 65 parts of xylene and 5 parts of ethyl acrylate into a four-necked flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, and stir and heat to 105°C. A mixed liquid consisting of 30 parts of methyl methacrylate, 25 parts of ethyl acrylate, 10 parts of butyl acrylate, 30 parts of acrylic acid, and 2.5 parts of azobisisobutyronitrile was added dropwise from the dropping funnel for 3 hours. After the dropwise addition, keep warm for 0.5 hour, add 0.5 parts of azobisisobutyronitrile and 10 parts of xylene, keep warm for another 2 hours, cool down and discharge to prepare acrylic acid prepolymer.

[0038] 1b. Preparation of matrix resin A-1 with self-polishing properties

[0039] In a three-neck flask equipped with a stirring device, a condenser, and a thermometer, add 300 parts of the acrylic acid prepolymer prepared in the above step 1a, 50.8 p...

Embodiment 2

[0041] 2a. Preparation of methacrylic acid prepolymer

[0042] Add 25 parts of n-butanol, 65 parts of xylene and 5 parts of ethyl acrylate into a four-necked flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, and stir and heat to 105°C. A mixed liquid consisting of 25 parts of methyl methacrylate, 20 parts of ethyl acrylate, 20 parts of butyl acrylate, 30 parts of methacrylic acid, and 2.5 parts of azobisisobutyronitrile was added dropwise from the dropping funnel for 3 hours. After the dropwise addition, keep warm for 0.5 hours, add 0.5 parts of azobisisobutyronitrile and 10 parts of xylene, keep warm for another 2 hours, cool down and discharge to prepare methacrylic acid prepolymer.

[0043] 2b. Preparation of matrix resin A-2 with self-polishing properties

[0044] In a there-necked flask equipped with a stirring device, a condenser, and a thermometer, add 300 parts of methacrylic acid prepolymers prepared in the above-mentioned step...

Embodiment 3

[0046] 3a. Preparation of Acrylic Prepolymer

[0047] In a four-neck flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, add 25 parts of propylene glycol methyl ether, 60 parts of xylene and 5 parts of cyclohexyl methacrylate under stirring, and heat to 105°C. From the dropping funnel, add dropwise a mixed liquid consisting of 30 parts of isooctyl acrylate, 25 parts of cyclohexyl methacrylate, 20 parts of methoxyethyl acrylate, 20 parts of acrylic acid, and 2.5 parts of azobisisobutyronitrile. Hours. After the dropwise addition, keep warm for 0.5 hours, add 0.5 parts of azobisisobutyronitrile and 10 parts of xylene, keep warm for another 2 hours, cool down and discharge to prepare acrylic acid prepolymer.

[0048] 3b. Preparation of matrix resin A-3 with self-polishing properties

[0049] In a three-necked flask equipped with a stirring device, a condenser, and a thermometer, add 300 parts of the acrylic acid prepolymer prepared in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com