Comb type acrylic resin of lateral chain grafting polyester resin and preparation method and application thereof

A technology of acrylic resin and polyester resin, which is applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc. It can solve the problems of comb-type acrylic resins that have not been seen, and achieve the purpose of prolonging the antifouling effect, The effect of high mechanical strength and good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

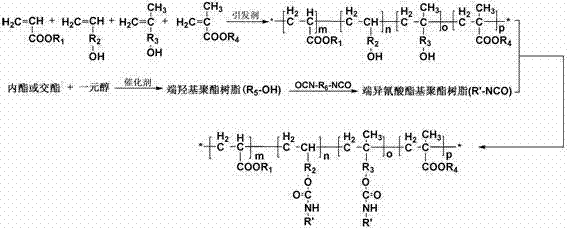

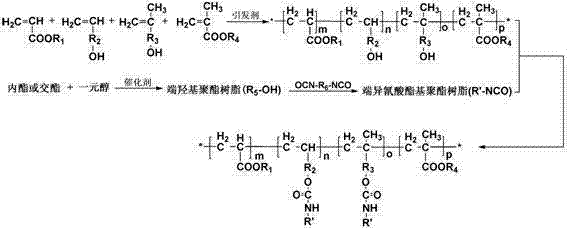

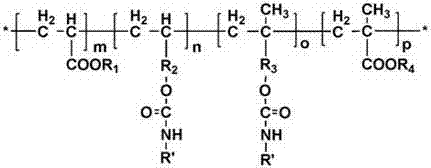

Method used

Image

Examples

Embodiment 1

[0025] a. Preparation of hydroxyacrylic resin

[0026] When preparing, first add 125g of xylene and 130g of butyl acetate into a 500ml four-neck flask, stir and heat to 90°C, then add 32g of methyl acrylate, 25g of n-butyl acrylate, 24g of ethyl methacrylate, n-methacrylate A mixture of 26 g of butyl ester, 7 g of hydroxyethyl acrylate, 1.8 g of azobisisobutyronitrile, and 1.5 g of dodecanethiol was added dropwise into a four-neck flask, added dropwise for 1 hour, and kept warm for 6 hours.

[0027] b. Preparation of polycaprolactone

[0028] 1 g of stannous chloride, 4 g of 1,4-butanediol, and 128 g of monomer ε-caprolactone were heated up to 170°C, mechanically stirred, and nitrogen was blown, and reacted for 10 h. After the reaction, the product was dissolved with dichloromethane and precipitated with methanol. The purified product was dried in an oven at 50° C. for 24 h to obtain the polycaprolactone prepolymer used in the present invention.

[0029] Above-mentioned cat...

Embodiment 2

[0034] a. Preparation of hydroxyacrylic resin

[0035] When preparing, first add 110g of xylene and 140g of butyl acetate into a 500ml four-neck flask, stir and heat to 90°C, then add 28g of methyl acrylate, 30g of n-butyl acrylate, 20g of ethyl methacrylate, n-methacrylate A mixture of 36 g of butyl ester, 8 g of hydroxyethyl acrylate, 2.0 g of azobisisobutyronitrile, and 2.0 g of dodecanethiol was added dropwise into a four-neck flask, added dropwise for 1 hour, and kept warm for 6 hours.

[0036] b. Preparation of polycaprolactone

[0037] 0.8g of stannous chloride, 2.6g of 1,4-butanediol, and 119g of monomer ε-caprolactone were heated up to 170°C, stirred mechanically, and reacted with nitrogen for 10h. After the reaction, the product was dissolved with dichloromethane and precipitated with methanol. The purified product was dried in an oven at 50° C. for 24 h to obtain the polycaprolactone prepolymer used in the present invention.

[0038] Above-mentioned catalyst can ...

Embodiment 3

[0043] a. Preparation of comb-type acrylic resin coating with side chain grafted polyester resin

[0044] The marine antifouling paint is composed of resin, plasticizer, filler and antifouling agent, and their weight percent ranges are 20-50, 1-15, 10-40 and 5-30 respectively. The resin solution is a comb-type acrylic resin solution of a side chain grafted polyester resin with a concentration of 25 to 55% by weight, and the solvent is petroleum ether, methyl acetone, ethyl acetate, butyl acetate, ethyl acetate, butylacetate ester, toluene, xylene butanol or a mixture of several in any proportion; the plasticizer is vaseline, chlorinated paraffin, adipate dicaprylic acid, dibutyl phthalate or dibutyl phthalate Octyl ester; the filler is one or more mixtures in arbitrary proportions in red iron oxide, calcium carbonate, natural diatomaceous earth, talcum powder, titanium dioxide, fumed silica solid particles or zinc oxide; The staining agent is one or several mixtures of copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com