Aqueous self-polishing antifouling coating substrate resin and antifouling coating prepared from same

A technology of antifouling coatings and matrix resins, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., to meet the needs of antifouling, easy to maintain, and friendly to the marine environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

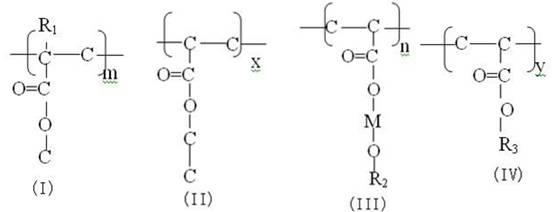

Method used

Image

Examples

Embodiment 1

[0035] The water-based self-polishing resin is prepared by a two-step process, the first step is to prepare a divalent metal ion-containing ethylenically unsaturated monomer (a1) CH 3 -COO-Zn-COO-(C 2 h 5 ) 2 Under the action of initiator benzoyl peroxide, with other metal-free ethylenically unsaturated monomer (a2)CH 3 OCO-CH(R 3 )=CH 2 A polymer is prepared by copolymerization, which is reacted with one or two basic compounds, and finally made into a water-based resin. Specific steps are as follows:

[0036] 1) Preparation of ethylenically unsaturated monomer (a1) containing a divalent metal ion

[0037] Weigh zinc or copper metal oxides or hydroxides, organic acids containing unsaturated double bonds such as acrylic acid with a molar ratio of 1:2, respectively. Add the stoichiometric organic mixed solvent and the weighed metal oxide or hydroxide into a four-necked bottle equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, and raise the...

Embodiment 2

[0045] 1. Preparation of metal-containing monomer a1-1

[0046] In a four-necked flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, 70 parts by mass of propylene glycol methyl ether and 40 parts by mass of zinc oxide were added under stirring, and heated to 80°C. A mixture of 45 parts by mass of methacrylic acid, 30 parts by mass of acrylic acid and 20 parts by mass of water was added dropwise from the dropping funnel for 3 hours. Keep warm until the mixture is clear and transparent. The metal-containing monomer a1-1 was prepared.

[0047] 2. Preparation of Waterborne Self-polishing Resin 1

[0048] In a four-neck flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, 52 parts by mass of propylene glycol methyl ether, 30 parts by mass of xylene and 5 parts of ethyl acrylate were added under stirring, and heated to 100°C. 25 parts by mass of methyl methacrylate, 45 parts by mass of ethyl acrylate, 5 p...

Embodiment 3

[0050] 1. Preparation of metal-containing monomer a1-2

[0051] In a four-necked flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, add 25 parts by mass of n-butanol, 75 parts by mass of xylene and 40 parts by mass of zinc oxide under stirring, and heat to 80°C. A mixture of 45 parts by mass of methacrylic acid, 30 parts by mass of acrylic acid and 20 parts by mass of water was added dropwise from the dropping funnel for 3 hours. Keep warm until the mixture is clear and transparent. The metal-containing monomer a1-2 was prepared.

[0052] 2. Preparation of water-based self-polishing resin 2

[0053] In a four-neck flask equipped with a stirring device, a condenser, a dropping funnel, and a thermometer, add 52 parts by mass of propylene glycol methyl ether, 30 parts by mass of xylene and 5 parts by mass of ethyl acrylate under stirring, and heat to 100°C. From the dropping funnel, drop by 25 parts by mass of methyl methacrylate, 45 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com