Rosin organic acid metal salt resin with chemical structural characteristics and performances of acrylate metal salt resin and preparation method and application of rosin organic acid metal salt resin

A metal salt, organic acid technology, applied in the chemical modification of natural resin, carboxylate preparation, organic chemistry and other directions, can solve the problem of lack of biocidal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

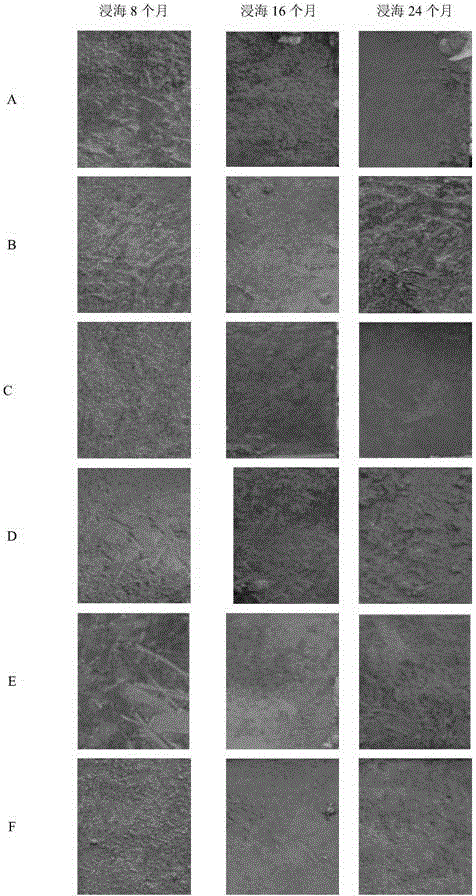

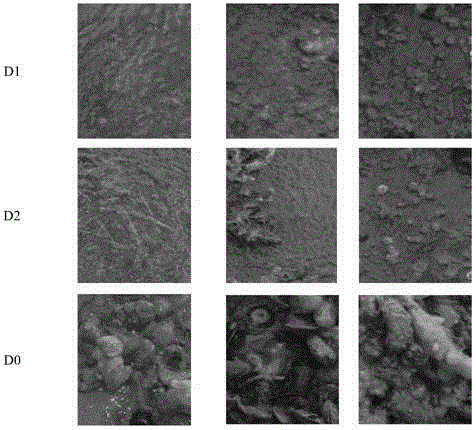

Image

Examples

Embodiment 1

[0109] Embodiment 1: the preparation of rosin organic acid metal salt resin of the present invention

[0110] The implementation steps of this embodiment are as follows:

[0111] Add 70 parts by weight of rosin sold under the trade name rosin by Zhengzhou Zhiyuan Chemical Products Co., Ltd., 80 parts by weight of benzoic acid and toluene solvent into a reactor equipped with a stirring device and a thermometer, and heat at a temperature of 80°C to make the rosin completely Dissolve, then add 12 parts by weight of zinc hydroxide sold under the trade name zinc hydroxide by Wenzhou Chemical Material Factory Company, the amount of the toluene solvent is 5.8 times the total weight of the reactants, and then react under the condition of a temperature of 130 ° C After 40 hours, the temperature was adjusted to 120° C. for dehydration until no water was distilled off, and the reaction was completed to obtain the rosin zinc benzoate resin.

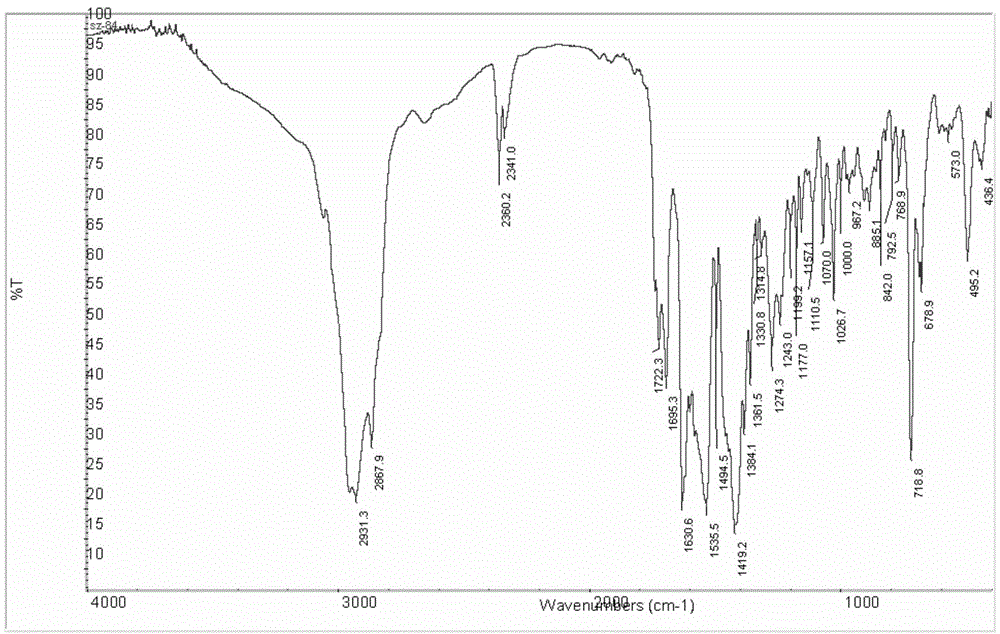

[0112] Conventional infrared spectrometry is ...

Embodiment 2

[0113] Embodiment 2: the preparation of rosin organic acid metal salt resin of the present invention

[0114] The implementation steps of this embodiment are as follows:

[0115] Add 40 parts by weight of disproportionated rosin sold under the trade name disproportionated rosin by Beijing Linxinlong Chemical Products Co., Ltd., 54 parts by weight of naphthenic acid organic acid and xylene solvent into a reactor equipped with a stirring device and a thermometer. Down heating makes the disproportionated rosin mixture dissolve completely, then add 2 parts by weight of copper hydroxide sold under the trade name copper hydroxide by Jiangsu Qiangsheng Functional Chemicals Co., Ltd., the amount of the xylene solvent is 2.2 times the total weight of the reactant, and then React at a temperature of 50°C for 160 hours, then adjust the temperature to 120°C for dehydration until no water is distilled off, and the reaction is completed to obtain the disproportionated rosin copper naphthena...

Embodiment 3

[0117] Embodiment 3: the preparation of rosin organic acid metal salt resin of the present invention

[0118] The implementation steps of this embodiment are as follows:

[0119] 90 parts by weight of dimerized rosin sold under the trade name DMER-145 rosin resin by Shenzhen Jintenglong Trading Co., Ltd., 30 parts by weight of salicylic acid organic acid and n-butanol solvent are added in the reactor equipped with stirring device and thermometer, Heating under the condition of temperature 80 ℃ makes dimerized rosin mixture dissolve completely, then add 30 parts by weight of magnesium hydroxide sold by trade name magnesium hydroxide by Yixing Bailing Fine Chemical Co., Ltd., the amount of described n-butanol solvent is The total weight of the reactants was 7.0 times, and then reacted at a temperature of 180° C. for 2 hours, and then adjusted to 120° C. for dehydration until no water was distilled out, and the reaction was completed to obtain the dimerized magnesium rosin salicy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com