Super-soft finishing agent of silicone oil

A finishing agent and ultra-soft technology, applied in fiber treatment, fiber type, textiles and papermaking, etc., can solve problems such as difficult repair, easy demulsification, sticking to rollers, etc., and achieve easy yellowing, less color change, and expansion The effect of scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

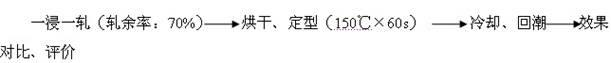

Method used

Image

Examples

Embodiment 1-1

[0016] Example 1-1 Preparation of α, ω-amino polysiloxane intermediate

[0017] In a 2000ml three-necked flask equipped with a constant speed electric stirrer and a thermometer, add 1230g of octamethylcyclotetrasiloxane (D4) and 50 grams of 1,1,3,3-tetramethyldiaminopropyl disilazane Oxygen, stir and heat up to about 90-95°C, then add 1.28g (CH 3 ) 4 NOH content of 10% (CH 3 ) 4 NOH alkali glue, heat preservation reaction for 6 hours, after the heat preservation is over, the temperature is raised to 135 ° C, and the heat preservation is 1 hour, and the catalyst (CH 3 ) 4 The NOH is fully decomposed, vacuumized slowly, and a large amount of low boiling material flows out. Under the condition of temperature of 150°C and relative vacuum degree of -99.9KPa, pull out the low boiling material for 1 hour until no material flows out. The synthesized product is a colorless transparent viscous liquid, the ammonia value is 0.345mmol / g, the viscosity is 50-55cs, and the volatile con...

Embodiment 1-2

[0018] Example 1-2 α, ω--The preparation of aminopolysiloxane intermediate

[0019] In a 2000ml three-necked flask equipped with a constant-speed electric stirrer and a thermometer, add 1640g of octamethylcyclotetrasiloxane (D4) and 50 grams of 1,1,3,3-tetramethyldiaminopropyl disilazane Oxygen, stir and heat up to about 90-95°C, then add 1.7g (CH 3 ) 4 NOH content of 10% (CH 3 ) 4 NOH alkali glue, heat preservation reaction for 6 hours, after the heat preservation is over, the temperature is raised to 135 ° C, and the heat preservation is 1 hour, and the catalyst (CH 3 ) 4 The NOH is fully decomposed, vacuumized slowly, and a large amount of low boiling material flows out. Under the condition of temperature of 150°C and relative vacuum degree of -99.9KPa, pull out the low boiling material for 1 hour until no material flows out. The synthesized product is a colorless transparent viscous liquid with an ammonia value of 0.26mmol / g, a viscosity of 100-110cs, and a volatile...

Embodiment 2-1

[0020] Example 2-1 Preparation of epoxy-terminated polyether and α, ω-aminopolysiloxane intermediate block polymerization

[0021] In a 2000ml three-necked flask equipped with a constant speed electric stirrer and a thermometer, add 800g of the α,ω-amino polysiloxane intermediate prepared in Example 1-1, 106g of epoxy-terminated polyether (epoxy-terminated polyether) The molecular weight of polyether is 920, a+b=3, n=14), 604g of ethylene glycol monobutyl ether, start stirring, after fully stirring for 30 minutes, slowly raise the temperature to about 80-85°C, keep the temperature for 20 hours, A transparent light yellow polyorganosiloxane polyether block copolymer of polysiloxane, amino group and polyether ternary block can be obtained, with a viscosity of 500-550cs and a solid content of 60±1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ammonia value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com