Preparation of block water-soluble silicon oil

A water-soluble silicone oil and block technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of fabric hand feeling decline, improve self-emulsification performance, solve the problem of easy demulsification and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

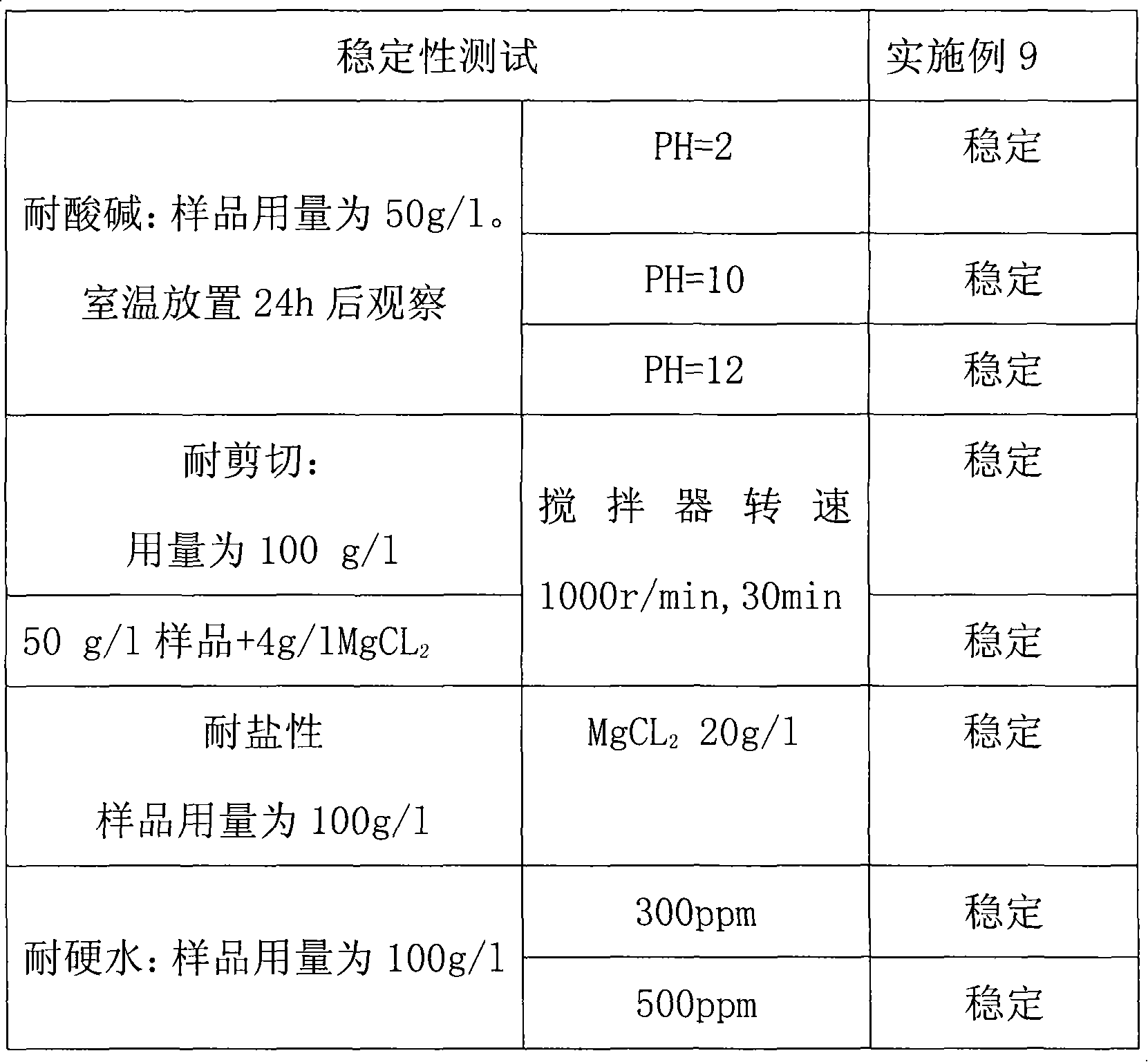

Examples

Embodiment 1

[0028] (1) Preparation of amidated amino coupling agent

[0029] Amidate 20 grams of γ-aminopropylmethyldimethoxysilane and 10 grams of formic acid (98% purity) in 150 grams of toluene, and stir (100 revolutions / min) for 1 hour at a temperature of 85°C. , Distilled water azeotropically with toluene (85°C), and then vacuumed out unreacted formic acid to obtain an amidated coupling agent.

[0030] (2) Preparation of hydrogen-terminated methyl siloxane intermediate

[0031] Put 80 grams of octamethylcyclotetrasiloxane and 20 grams of 1,1,3,3-tetramethyldisiloxane into a four-necked bottle, and simultaneously add 5 grams of the above two raw materials prepared in step (1) Amidated coupling agent, stir and react for 0.5h (80 revolutions per minute) at a temperature of 60°C, add 0.5 g of concentrated sulfuric acid, and perform an equilibrium reaction at a temperature of 70°C for 10 hours, and then vacuum to remove low molecular weight substances. The hydrogen-terminated methyl siloxane i...

Embodiment 2

[0037] Change 20 grams of γ-aminopropyl methyl dimethoxysilane in Example 1 to 20 grams of γ-aminopropyl ethyl dimethoxy silane, and 80 grams of octamethylcyclotetrasiloxane to 80 Grams of low-viscosity hydroxy silicone oil (25℃, 50mp*s), 0.5g of concentrated sulfuric acid changed to 0.4g of trifluoromethanesulfonic acid, allyl polyether used CH 2 =CHCH 2 O(C 2 H 4 O) a H(a=20), the isopropanol was changed to toluene, the platinum catalyst was a solution of chloroplatinic acid in isopropanol, and the rest were the same as in Example 1.

Embodiment 3

[0039] Replace 20 grams of γ-aminopropylmethyldimethoxysilane in Example 1 with 20 grams of γ-aminoethylmethyldimethoxysilane, and change 80 grams of octamethylcyclotetrasiloxane to 80 G low-viscosity hydroxy silicone oil (25℃, 70mp*s), 0.5 g concentrated sulfuric acid changed to 0.3 g activated clay, allyl polyether used CH 2 =CHCH 2 O(C 2 H 4 O) a H (a=10), isopropanol was changed to butyl acetate, platinum chloride was used as the absolute ethanol solution of platinum chloride, and the rest were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com