A kind of styrene-acrylic emulsion for modified cement mortar and preparation method thereof

A technology for cement mortar and styrene-acrylic emulsion, applied in the field of styrene-acrylic emulsion for modified cement mortar and its preparation, can solve the problem of imperfect, non-metasomatic mortar and workability of emulsion stability, adhesion, water resistance, and no polymerization involved. It can solve the problems such as the influence of polymer emulsion and mortar compatibility polymer emulsion, and achieve the effect of improved flexibility and water resistance, less loss over time, and improved fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

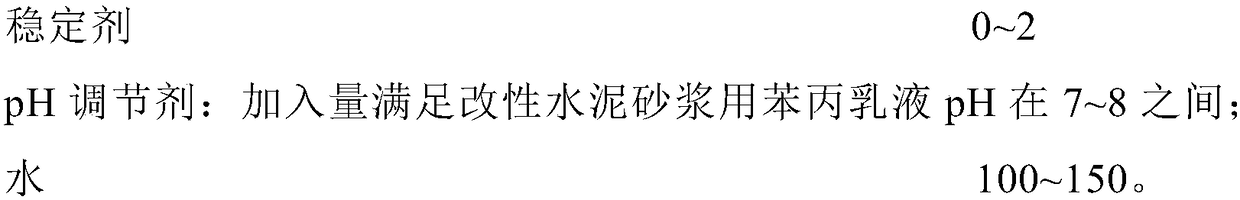

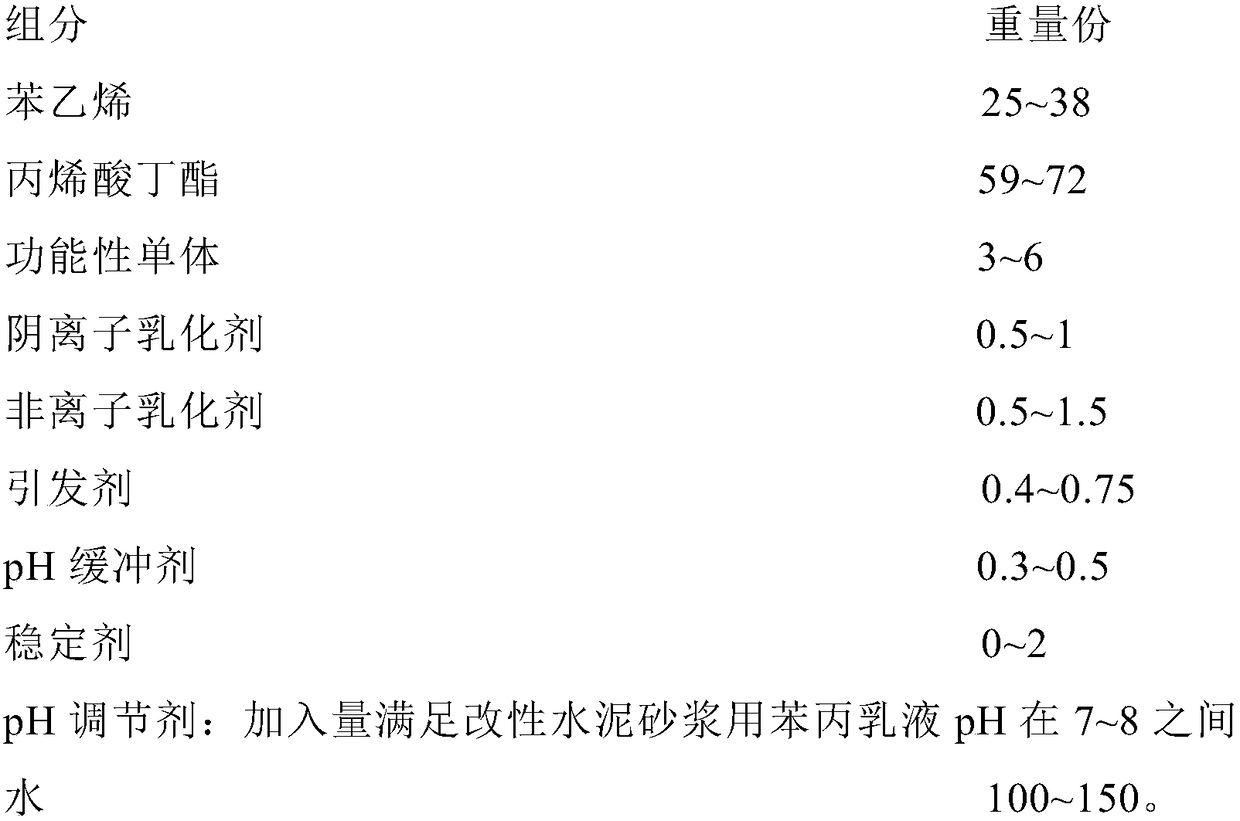

[0061] Prepare a styrene-acrylic copolymer emulsion with a glass transition temperature between -30 and -20°C calculated according to the FOX formula.

[0062] (1) Preparation of mixed emulsifier: Dissolve 1 part of sodium lauryl sulfate and 1.5 parts of alkylphenol polyoxyethylene ether OP10 in 16 parts of water to obtain a mixed emulsifier solution for later use.

[0063] (2) Dissolve 0.6 parts of ammonium persulfate in 30 parts of water to obtain an initiator solution.

[0064] (3) Dissolve 0.3 parts of sodium bicarbonate in 3 parts of water to obtain a pH buffer solution.

[0065] (4) Mix 28.5 parts of styrene, 66.5 parts of n-butyl acrylate, 2 parts of acrylic acid, 2 parts of N-methylolacrylamide, and 1 part of hydroxyethyl methacrylate to obtain a mixed monomer.

[0066] (5) Preparation of pre-emulsion. Add 95% of the mixed emulsifier in (1) and all the pH buffer solutions in (3) to a four-neck flask, and add all of (4) dropwise within 30mins under the conditions of a...

Embodiment 2

[0072] Calculate the styrene-acrylic copolymer emulsion with a glass transition temperature between -20 and -10°C according to the FOX formula.

[0073] (1) Preparation of mixed emulsifier: Dissolve 0.5 part of sodium lauryl sulfate and 1 part of alkylphenol polyoxyethylene ether OP10 in 16 parts of water to obtain a mixed emulsifier solution for later use.

[0074] (2) Dissolve 0.6 parts of ammonium persulfate in 30 parts of water to obtain an initiator solution.

[0075] (3) Dissolve 0.4 parts of sodium bicarbonate in 4 parts of water to obtain a pH buffer solution.

[0076] (4) Mix 33.4 parts of styrene, 62.1 parts of n-butyl acrylate, 1.5 parts of acrylic acid, 2 parts of N-methylolacrylamide, and 1 part of hydroxyethyl methacrylate to obtain a mixed monomer.

[0077] (5) The preparation of the pre-emulsion is the same as in Example 1.

[0078] (6) Prepare seed emulsion. With embodiment 1. The difference is that the water added in the reaction vessel is 94 parts.

[0...

Embodiment 3

[0083] Calculate the styrene-acrylic copolymer emulsion with a glass transition temperature between -20 and -10°C according to the FOX formula.

[0084] (1) Preparation of mixed emulsifier: Dissolve 0.5 parts of sodium lauryl sulfate and 1.5 parts of fatty alcohol polyoxyethylene ether AEO9 in 16 parts of water to obtain a mixed emulsifier solution for later use.

[0085] (2) Dissolve 0.6 parts of ammonium persulfate in 30 parts of water to obtain an initiator solution.

[0086] (3) Dissolve 0.3 parts of sodium bicarbonate in 3 parts of water to obtain a pH buffer solution.

[0087] (4) Combine 34 parts of styrene, 63 parts of n-butyl acrylate, 1 part of methacrylic acid, 1 part of N-methylol acrylamide, and 1 part of hydroxyethyl methacrylate to obtain a mixed monomer.

[0088] (5) The preparation of the pre-emulsion is the same as in Example 1.

[0089] (6) Prepare seed emulsion. With embodiment 1. The difference is that the amount of water added to the reaction vessel i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com