Novel pilot test setter

A setting machine, a new type of technology, applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of fabric broken warp and weft, can not effectively achieve rapid cooling, time-consuming, etc., to achieve high-efficiency heating Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

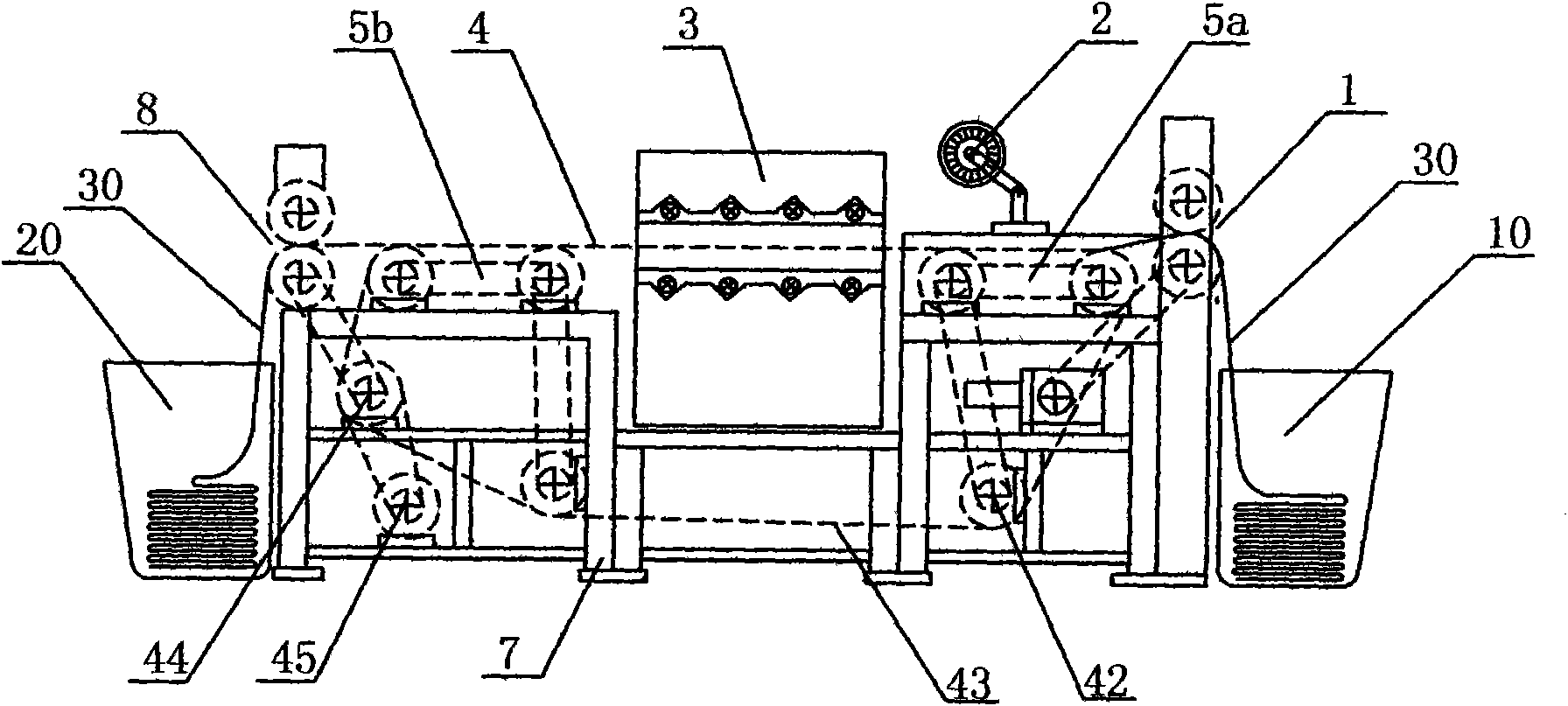

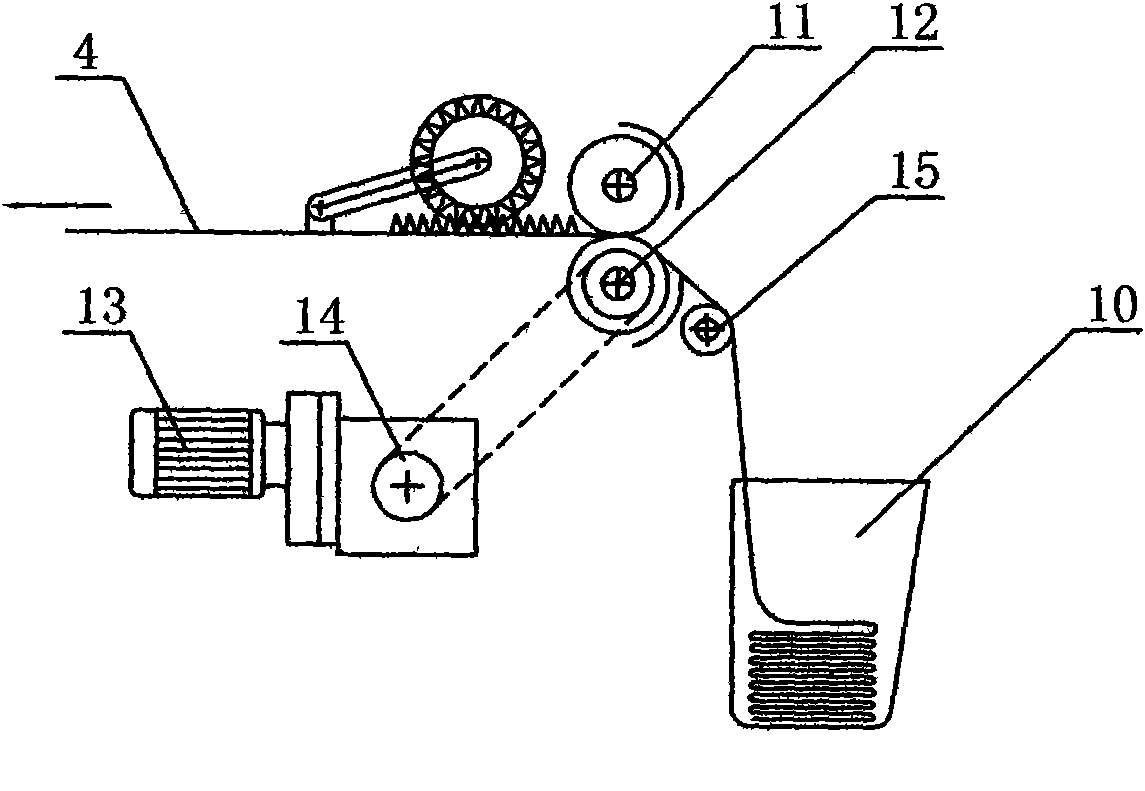

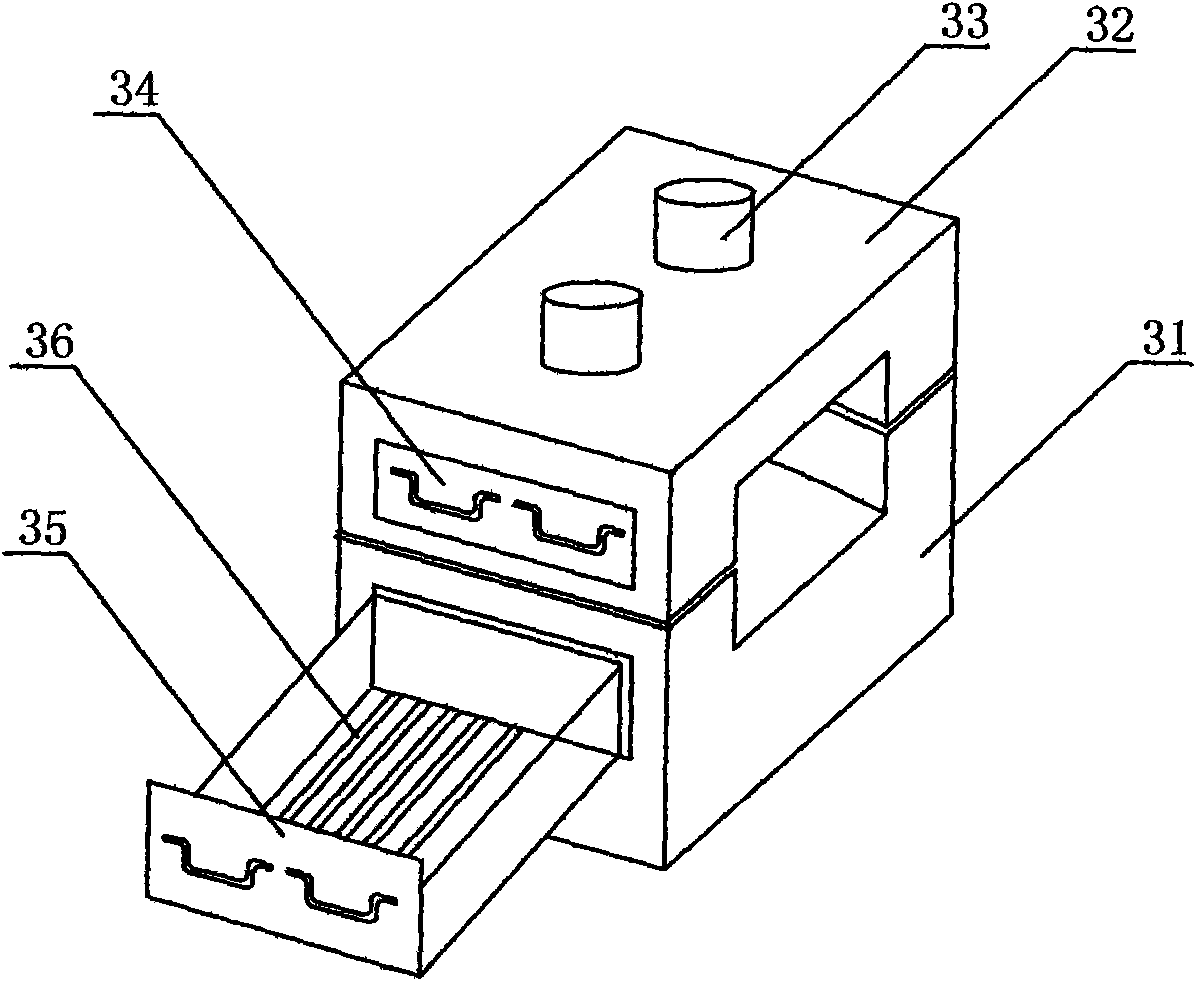

[0027] as attached figure 1 As shown, the new pilot-test setting machine of the present invention includes a frame 7, and the cloth inlet barrel 10 and the cloth outlet barrel 20 are installed at both ends of the frame 7, and are respectively used to place cloth samples 30, and the transmission device 4 is installed on the frame 7, along the conveying device 4 from the cloth inlet end to the cloth outlet end, a cloth feeding and overfeeding transmission device 1, a wool pressing wheel 2, a first expanding device 5a, an infrared oven 3, a second expanding device 5b and an outlet Cloth cooling device 8.

[0028] combine Figure 4 , Figure 5 As shown, the transmission device 4 is installed on the frame 7, connecting the cloth inlet end and the cloth outlet end, including several sprockets 42 installed on the frame 7, and a chain conveyor belt 43 with a needle plate 41 set on the sprocket 42 , sprocket 42 and chain conveyer belt 43 are provided with 2 groups altogether, are le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com