Gas-floatation rotational-flow coalescence composite type sewage oil-removing device

A composite, coalescing technology, used in oil/oil/float removal devices, flotation water/sewage treatment, centrifugal separation water/sewage treatment, etc. problems, to achieve the effect of improving the finishing effect, saving investment and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

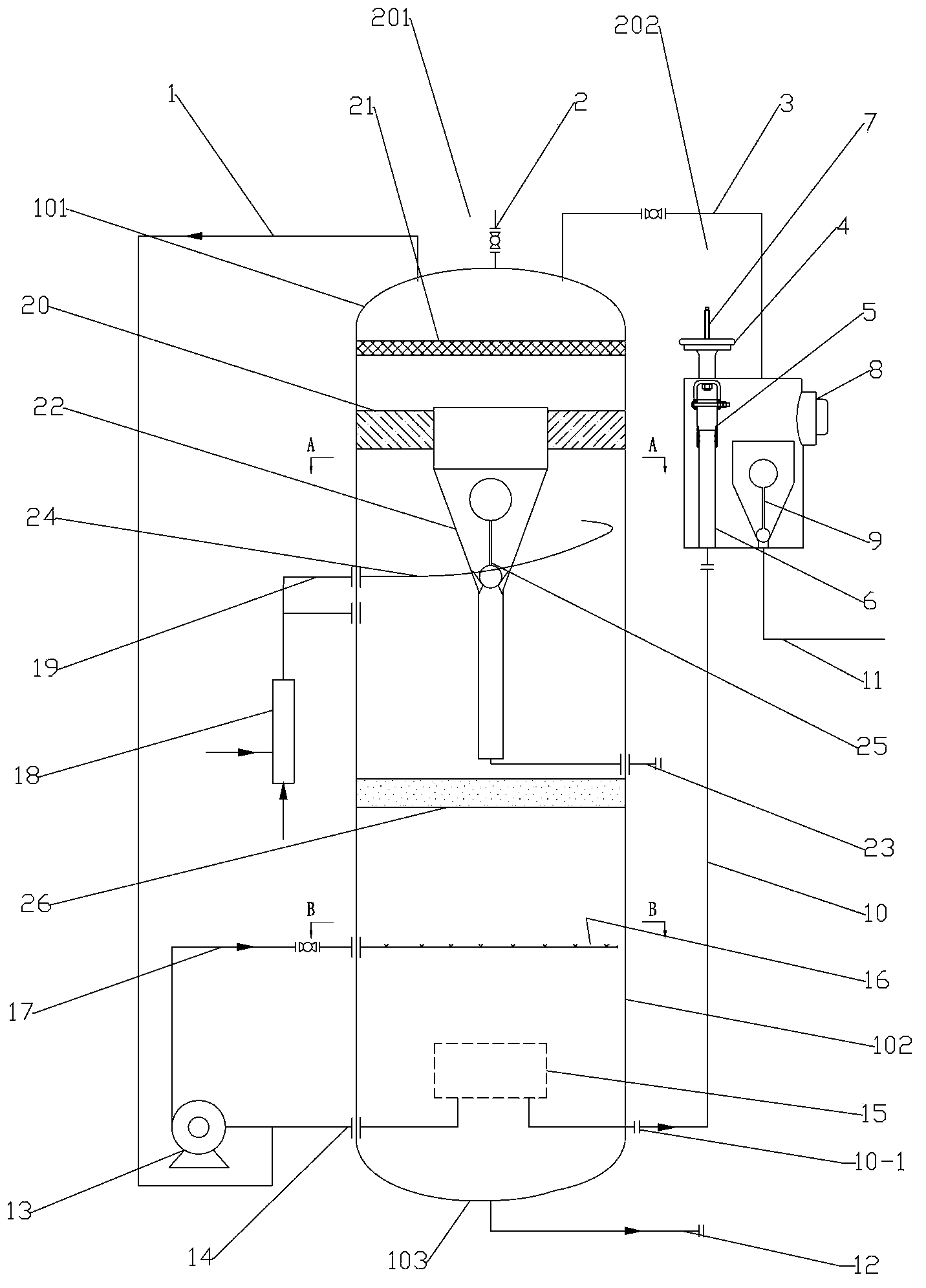

[0024] see Figure 1-Figure 4 , is the implementation example of the air flotation swirl flow coalescence composite sewage deoiling device in the present invention, but the present invention is not limited to the following examples;

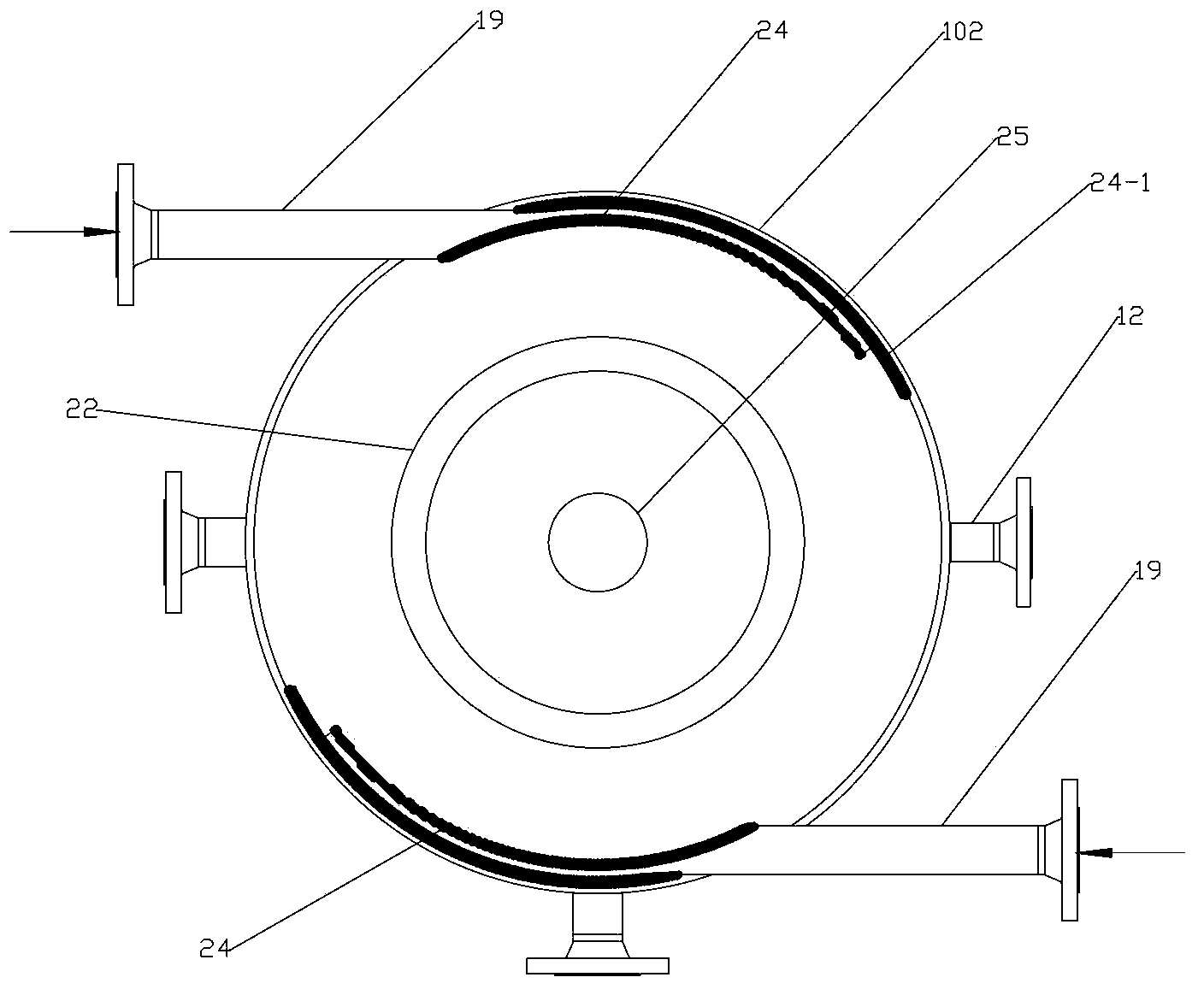

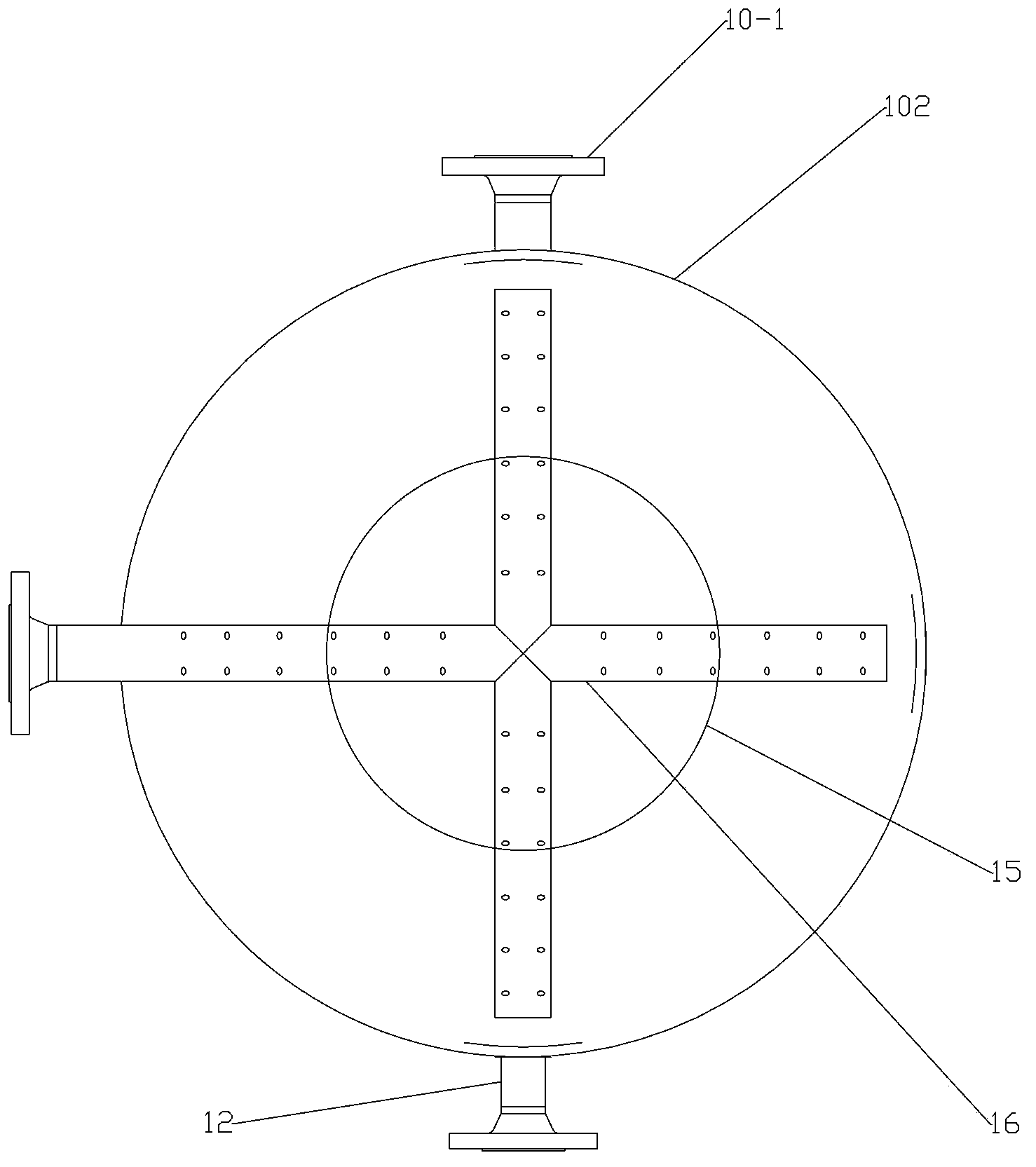

[0025] The air flotation swirling flow coalescence composite sewage degreasing device is mainly composed of a multifunctional separation tank 201, a two-stage gas-water mixing device, and an adjustment control box 202; the multifunctional separation tank 201 is a vertical cylindrical tank, which consists of a cylinder body 102, Composed of an upper head 101 and a lower head 103, the upper part of the equipment has a tangential liquid inlet 19, the middle part has an oil outlet 23, the lower part has a circulating water inlet / outlet 17, the bottom has a sewage outlet 12, and the top has a The exhaust port 2 and the connecting pipe 1, 3; the liquid inlet adopts a tangential direction to enter, and the liquid inlet in the tank is provided with a div...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com