Complex curved face grinding and polishing system and method

A technology for complex curved surfaces and workpiece surfaces, which is applied in the field of grinding and polishing systems for complex curved surfaces to reduce complexity, prevent abnormal situations, and improve completion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

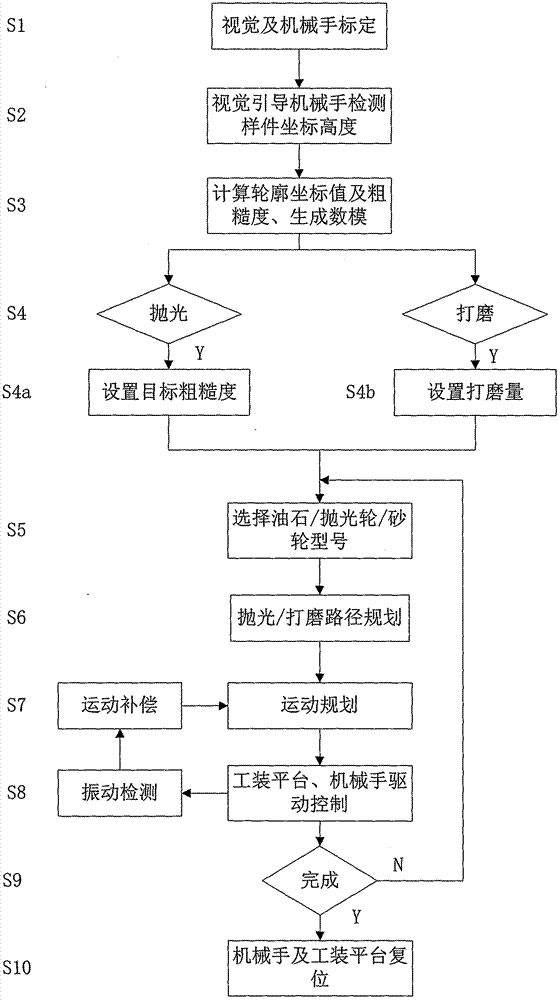

[0031] In order to make the purpose, technical solution, and advantages of the present invention more detailed, the present invention will be further described in detail below in combination with specific examples and with reference to the accompanying drawings.

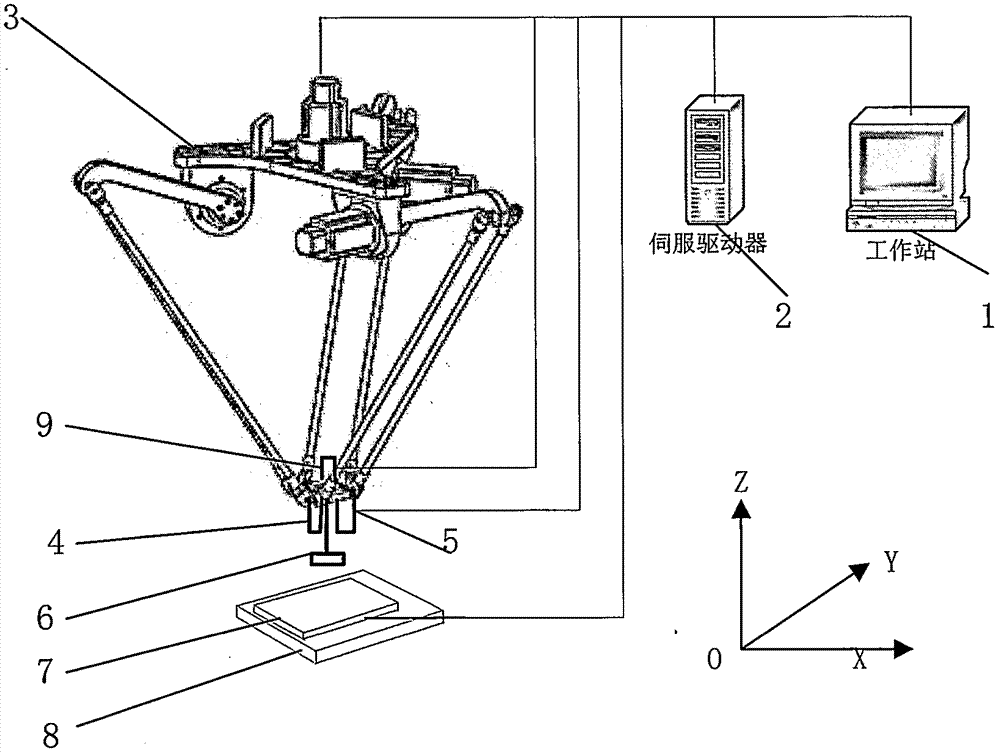

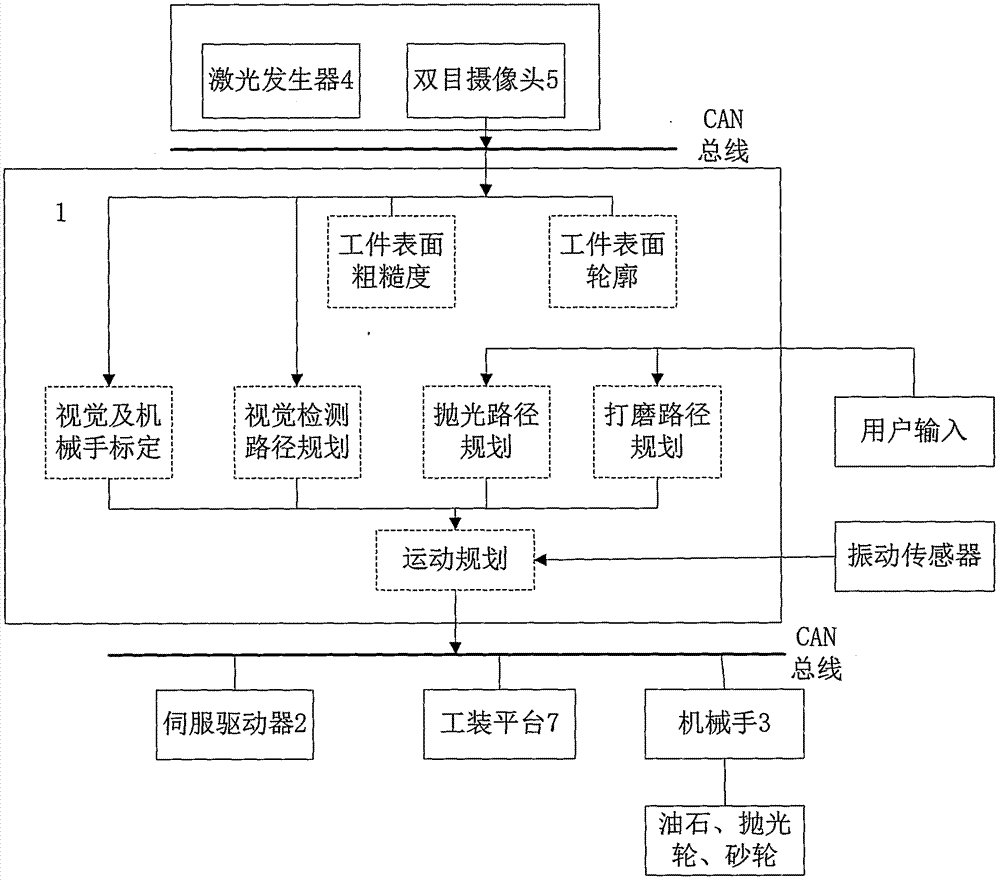

[0032] Such as figure 1As shown, the complex curved surface polishing system includes a workstation (1), a servo driver (2), a three-degree-of-freedom industrial manipulator (3), a laser generator (4), a camera (5), a manipulator end clamp (6), a three-freedom Tooling platform (7), tooling platform base (8), vibration sensor (9). A workstation (1), a servo drive (2), a manipulator (3), a camera (5), a tooling platform (7), and a vibration sensor (9) communicate through a CAN bus. The laser generating device (4) and the camera (5) constitute a visual detection device to guide the manipulator (3) to detect the contour and roughness of the workpiece; the workstation (1) obtains the contour detection value and the rough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com