Cationoid polyurethane and modified silicon oil composite water dispersion, preparation and applications

A cationic, polyurethane technology, applied in textiles, papermaking, fiber treatment, etc., can solve problems such as difficulty in obtaining nano-scale aqueous dispersions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In a four-neck flask equipped with a condenser and a stirring device, add 30 g (10 mmol) of dehydrated polyether N230 and 10.7 g (48 mmol) of IPDI, and react in a water bath at 60° C. for 10 h. Add 6.54g (30mmol) CE-3 chain extender, continue to react at 60°C for 4h, add 1.0g of isopropanol to block, and react for 3h. Cool down to 40°C, add 15.0g of acetone solvent and 15.0g of polyether modified silicone oil ETS. Add 4.0g (67mmol) acetic acid for neutralization for 15min. 200 g of water was added dropwise with stirring to complete the emulsification. The solvent is removed under vacuum to obtain a composite aqueous dispersion of cationic polyurethane and modified silicone oil, with a dispersed particle diameter of 40 nm and a solid content of about 25%.

Embodiment 2

[0050] In a four-neck flask equipped with a condenser and a stirring device, add 30 g (10 mmol) of dehydrated polyether N230 and 5.3 g (24 mmol) of IPDI, and react in a water bath at 80° C. for 4.5 h. Add 2.18g (10mmol) CE-3 chain extender, continue to react at 80°C for 2h, add 1.0g of isopropanol to block, and react for 2h. Cool down to 40°C, add 10.0g of acetone solvent and 6.0g of polyether epoxy modified silicone oil ETES. Add 1.2g (20mmol) acetic acid for neutralization for 15min. 130 g of water was added dropwise with stirring to complete the emulsification. The solvent is removed under vacuum to obtain a composite aqueous dispersion of cationic polyurethane and modified silicone oil, with a dispersed particle diameter of 50 nm and a solid content of about 25%.

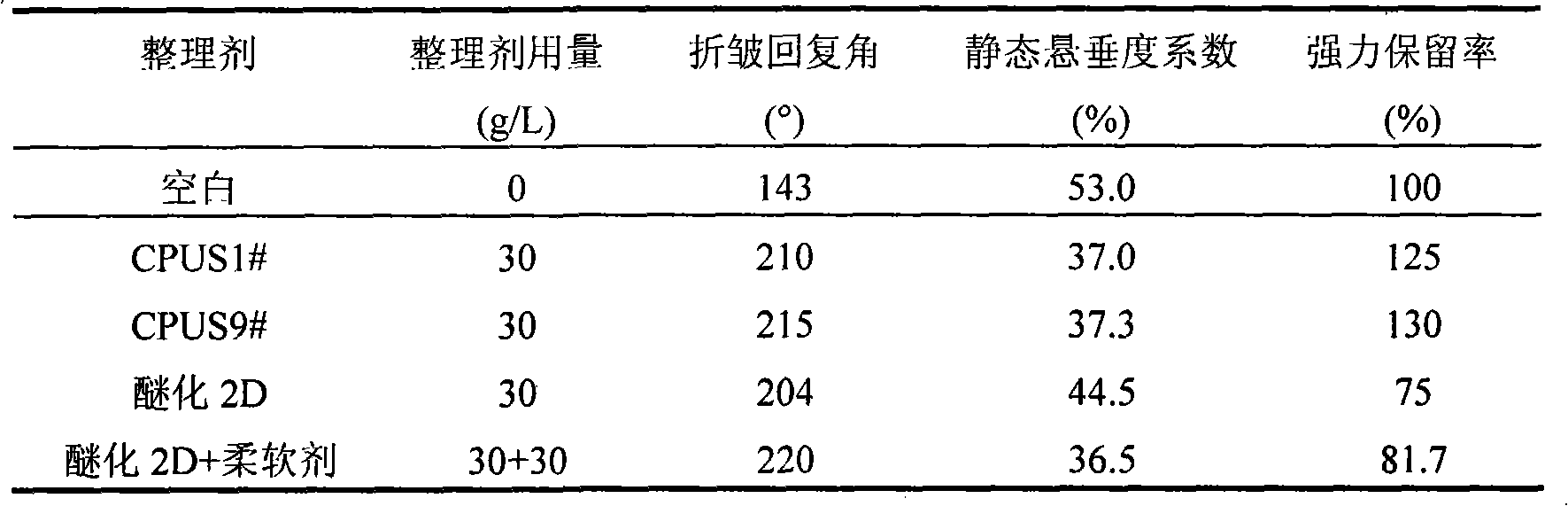

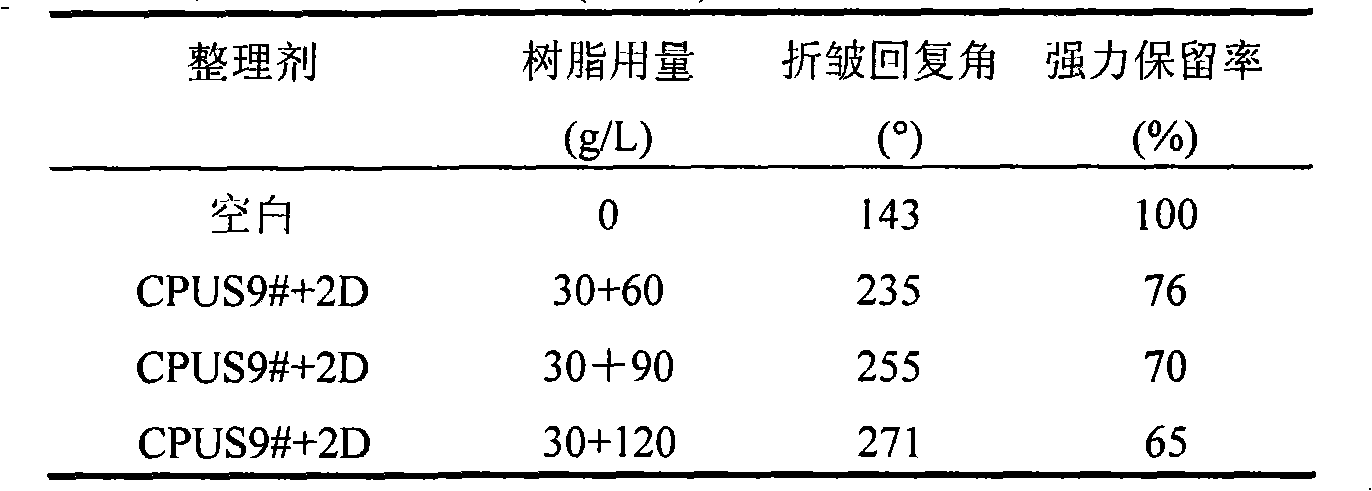

[0051] Other similar formulations are listed in Table 1. Reaction steps and condition are with example 2.

[0052] Table 1 Preparation of polyurethane / polymer amino silicone oil composite aqueous dispersion ...

Embodiment 9

[0055] Add 40g (10mmol) of dehydrated polyether N240 and 10.7g (48mmol) of IPDI into a four-neck flask equipped with a condenser and a stirring device, and react for 4.5h in a water bath at 80°C. Add 5.7g (30mmol) CE-2 chain extender, continue to react at 80°C for 2h, add 1.0g of isopropanol to block, and react for 2h. Cool down to 40°C, add 15.0g tetrahydrofuran solvent and 25.0g polyether modified silicone oil ETS. Add 3.60g (60mmol) acetic acid for neutralization for 15min. 200 g of water was added dropwise with stirring to complete the emulsification. The solvent is removed under vacuum to obtain a composite aqueous dispersion of cationic polyurethane and modified silicone oil, with a dispersed particle diameter of 60 nm and a solid content of about 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com