Method for preparing crease-resistant cotton fabric from silica sol

A wrinkled cotton fabric, silica sol technology, applied in the directions of plant fibers, textiles and papermaking, fiber processing, etc., can solve the problems of uneven external force load, decreased fabric strength, mobility restrictions, etc., to improve the strength decrease problem, The effect of improving tensile breaking strength and increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

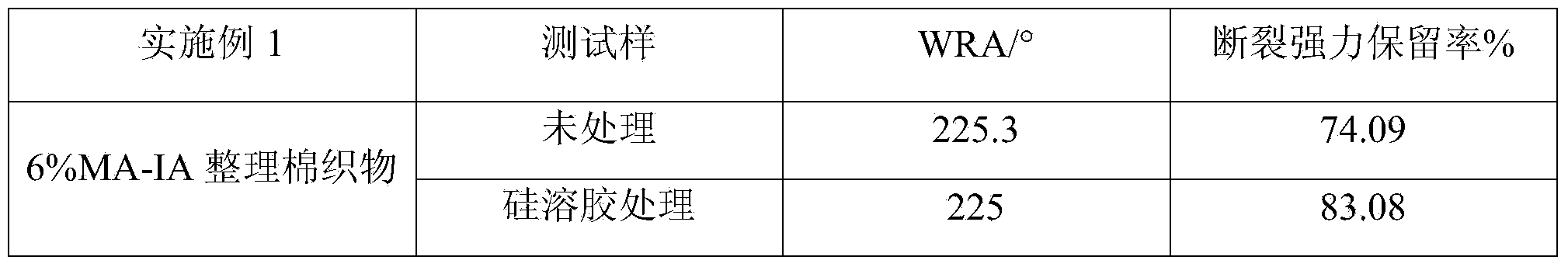

Embodiment 1

[0024] 2.164g catalyst (NH 4 ) 2 SO 4 , 9.32g of Na 2 SiO 3 9H 2 O was dissolved in 200mL of deionized water successively, then 6g of acid release agent DL-pantothenolactone was added to the solution, stirred rapidly to dissolve, the cotton fabric was immersed in the above solution, the temperature was controlled at 18°C, and after 24h, two soaking and two rolling , with a liquid retention rate of 80%, dry at 80°C for 3 minutes, wash with water for 10 minutes, and then dry at 80°C for 3 minutes;

[0025] Both the above-mentioned cotton fabrics and untreated cotton fabrics were immersed in the anti-wrinkle finishing solution for 3 minutes, then dipped and rolled twice, the liquid retention rate was 85%, dried at 100°C for 10 minutes, and then baked at 180°C for 1.5 minutes. The anti-wrinkle finishing solution includes: MA-IA anti-wrinkle finishing agent with a mass fraction of 6%, sodium hypophosphite, potassium peroxodisulfate and triethanolamine, and the balance is deion...

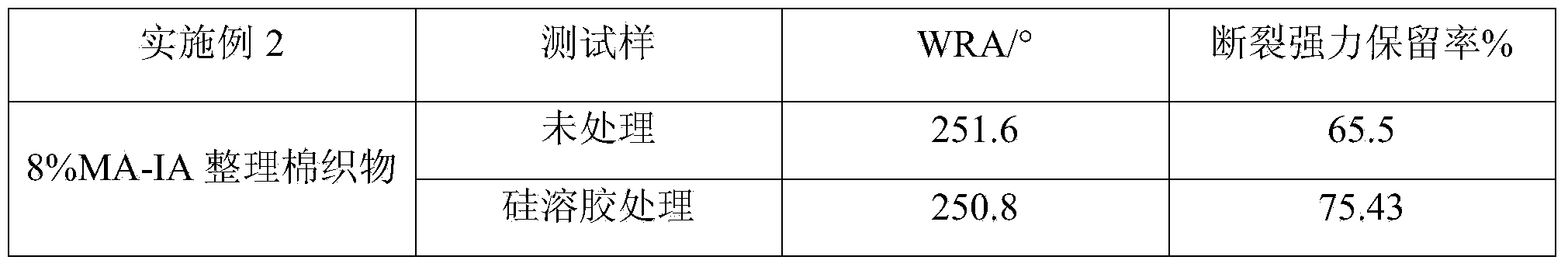

Embodiment 2

[0027] 9.32g Na 2 SiO 3 9H 2 O was dissolved in 200mL deionized water, then 6g of acid release agent DL-pantothenolactone was added to the solution, stirred rapidly to dissolve, the cotton fabric was immersed in the above solution, the temperature was controlled at 22°C, and after 24h, two dipping and two padding were performed. The liquid-carrying rate is 80%, dried at 80°C for 3 minutes, washed with water for 10 minutes, and then dried for 3 minutes;

[0028] Both the above-mentioned cotton fabrics and untreated cotton fabrics were immersed in the anti-wrinkle finishing solution for 3 minutes, then dipped and rolled twice, the liquid retention rate was 85%, dried at 100°C for 10 minutes, and then baked at 180°C for 1.5 minutes. The anti-wrinkle finishing solution includes: MA-IA anti-wrinkle finishing agent with a mass fraction of 8%, sodium hypophosphite, potassium peroxodisulfate and triethanolamine, and the balance is deionized water. Wherein the mol ratio of MA and IA...

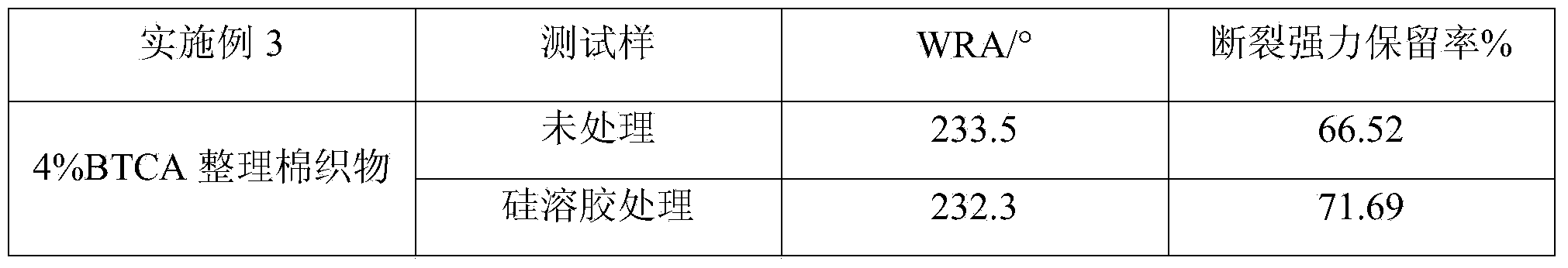

Embodiment 3

[0030] 9.32g Na 2 SiO 3 9H 2 O was dissolved in 200mL of deionized water, then 6g of acid release agent DL-pantothenolactone was added to the solution, stirred rapidly to dissolve, the cotton fabric was immersed in the above solution, the temperature was controlled at 20°C, and after 24 hours, two soaking and two rolling were performed. The liquid-carrying rate is 80%, dried at 80°C for 3 minutes, washed with water for 10 minutes, and then dried for 3 minutes;

[0031] Both the above-mentioned cotton fabric and the untreated cotton fabric were immersed in the anti-wrinkle finishing solution for 5 minutes, then dipped twice and rolled twice, with a liquid retention rate of 85%, dried at 80°C for 3 minutes, and then baked at 180°C for 1.5 minutes. The anti-wrinkle finishing solution contains: BTCA anti-wrinkle finishing agent with a mass fraction of 4% and sodium hypophosphite, wherein the molar ratio of sodium hypophosphite to BTCA is 1:1, triethanolamine is 2% of the mass of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com