A low-strength fiber pulling and cutting device

A technology of strong fiber, pulling and cutting and making sliver, applied in the direction of fiber bundles into fiber sliver/yarn, etc., can solve the problems of difficult carding of low-strength functional fibers, etc., to reduce the pulling force and reduce the pulling force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

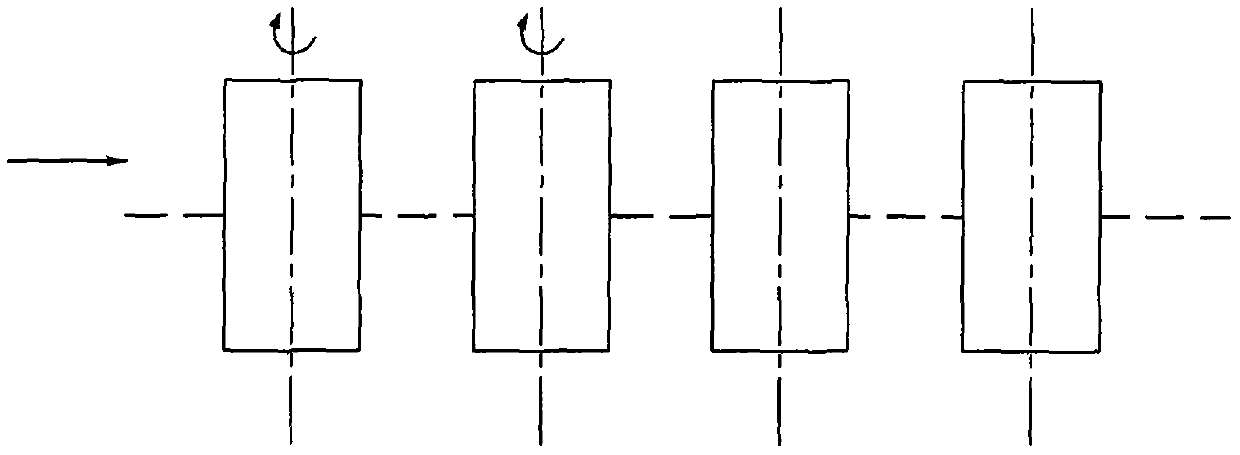

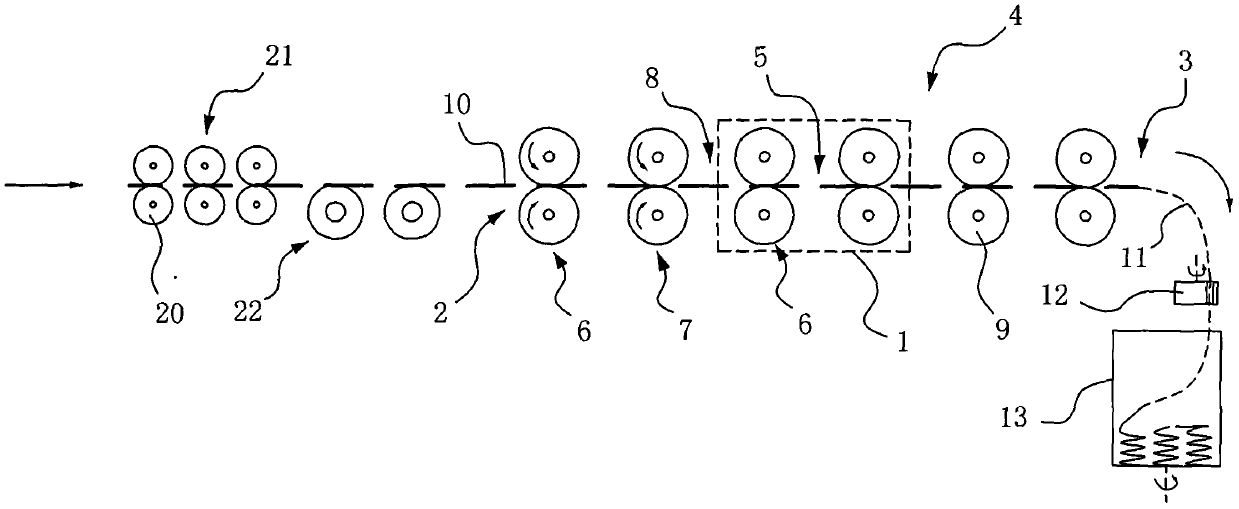

[0036] Such as figure 1As shown in , it is a schematic diagram of the structure of the traditional pulling roller group, such as figure 2 , 3 As shown, a low-strength fiber stretching and stripping device includes a stretching device 4 with a feed end 2 and a discharge end 3 composed of multiple sets of stretching rolls 1, and each set of stretching rolls 1 respectively form a stretching area 5, each group of stretching rolls 1 is composed of a pair of drafting rolls 6 and stretching rolls 7 that mesh with each other, the stretching between adjacent stretching rolls 1 A drafting transition zone 8 is formed between the cutting roll 7 and the drafting roll 6, and the drafting roll 6 and the drafting roll 7 are both composed of two roller bodies 9 meshing with each other, and the drafting in each drafting zone 5 The horizontal distance along the axial direction of the roller body 9 between the roller 6 and the cutting roller 7 gradually increases or decreases gradually. In th...

Embodiment 2

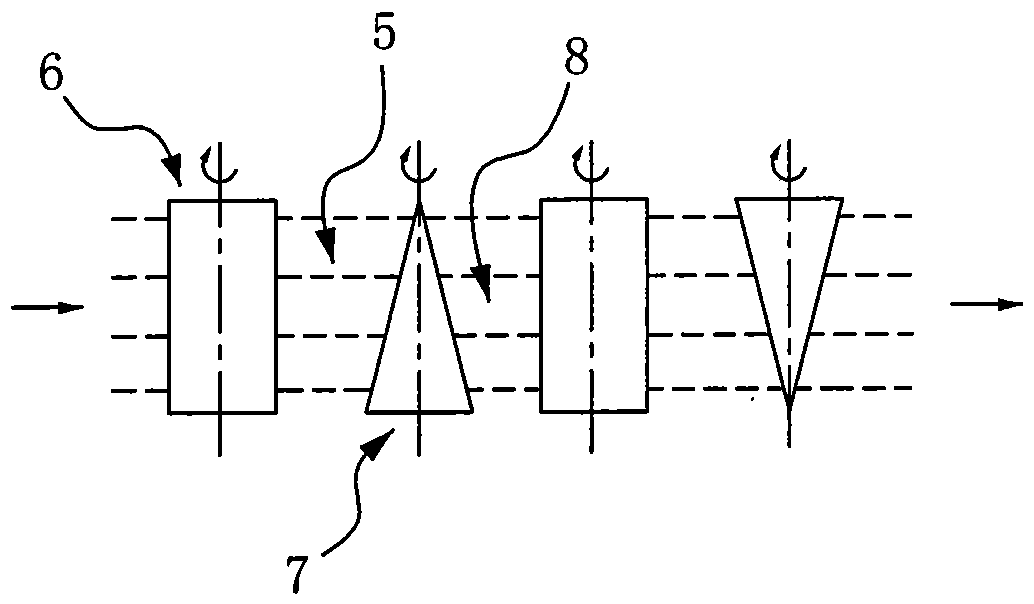

[0043] The same parts of this embodiment and Embodiment 1 will not be repeated, and the difference is that: Figure 4 As shown, the axial longitudinal cross-sectional shape of the roll body 15 of the stretching roll 14 is set as a trapezoidal structure. The roller bodies 15 of the adjacent stretching rollers 14 are arranged parallel to each other and opposite to each other.

Embodiment 3

[0045] The same parts of this embodiment and Embodiment 1 will not be repeated, and the difference is that: Figure 5 As shown, the horizontal distance between the drafting roller 17 and the drafting roller 18 in each drafting zone 16 along the axial direction of the roller body 19 changes alternately. The longitudinal cross-sectional shape of the roll body 19 of the stretching roll 18 in the axial direction is configured as a wave structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com