Directly-lapped three-carding spunlace non-woven fabric and preparation method thereof

A technology of spunlace non-woven fabrics and non-woven fabrics, which is applied in the direction of non-woven fabrics, textiles, and papermaking. It can solve the problems of slow speed, high cost, and low production capacity, reduce the difference in vertical and horizontal strength, and improve tensile strength. Breaking strength, effect of expanding application range and field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

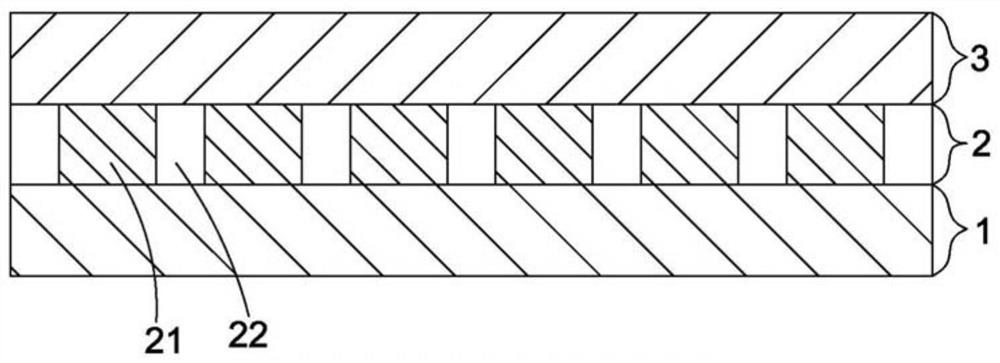

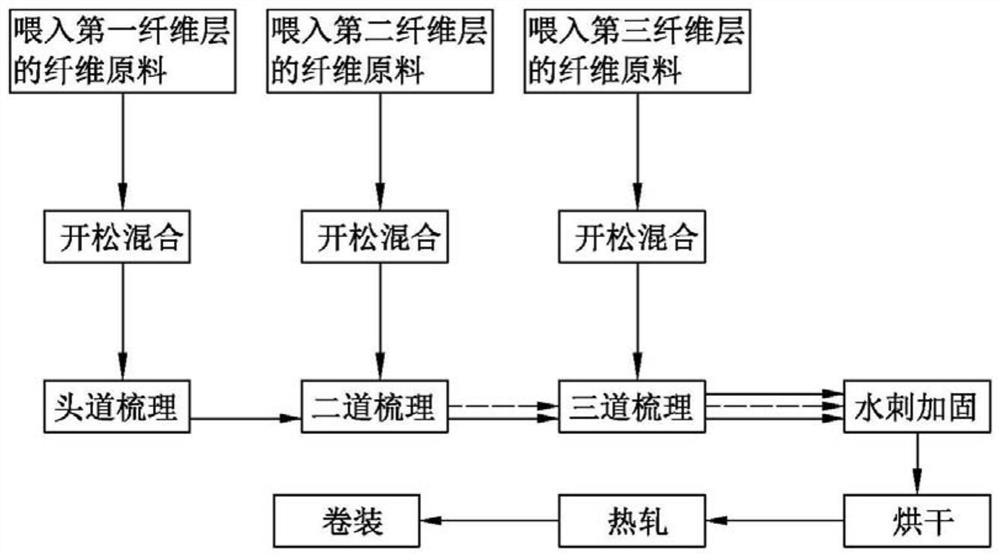

[0026] In order to describe the technical content, structural features, goals and effects of the application in detail, the technical solutions in the embodiments of the application will be described below in conjunction with the accompanying drawings in the embodiments of the application. Obviously, the described embodiments are only the present application. Claim some of the examples, not all of them. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide detailed illustrations of various exemplary embodiments, or implementations, of the invention. However, various exemplary embodiments may be practiced without these specific details, or with one or more equivalent arrangements. Furthermore, the various exemplary embodiments may differ, but are not necessarily exhaustive. For example, the specific shape, configuration, and characteristics of an exemplary embodiment may be used or implemented in another exemplar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com