Composite of support matrix and collagen, and process for producing support substrate and composite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

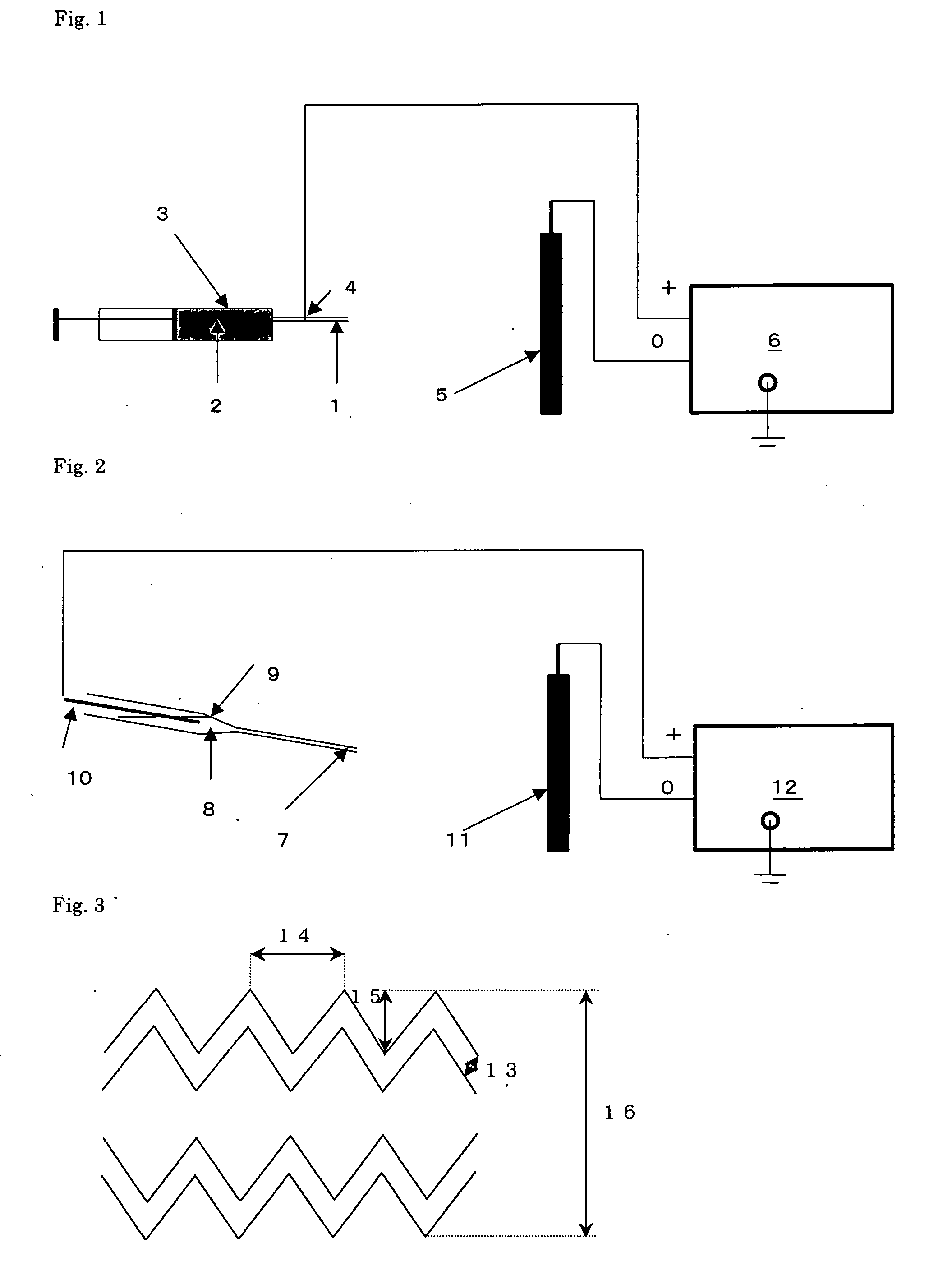

[0091] A dope was prepared by mixing 1 g of polylactic acid and 8 g of methylene chloride at room temperature (25° C.). An apparatus such as shown in FIG. 2 was used for 5 minutes of discharge of the solution to a fiber substance collecting electrode 5 (2 mm diameter, 200 mm length, 70-S surface roughness), causing rotation at 60 rpm. During this time, the collecting electrode 5 was rotated 150 rpm in the circumferential direction. The inner diameter of the ejection nozzle 1 was 0.8 mm, the voltage was 12 kV, and the distance from the ejection nozzle 1 to the fiber substance collecting electrode 5 was 10 cm. The end of the fiber structure collected at the fiber substance collecting electrode 5 was held fixed against a finger while the fiber substance collecting electrode 5 was pulled out toward the end fixed against the finger, to obtain a polylactic acid tube. The obtained polylactic acid tube had a diameter of 2 mm, a length of 20 mm, a basis weight of 20 g / m2, a bellows-shaped se...

example 2

[0092] The same treatment was carried out as in Example 1, except that the basis weight was 40 g / m2.

example 3

[0093] A 2 mm-diameter rod was reinserted into the polylactic acid tube obtained in Example 1, and this was fixed at the center of a 3 mm diameter tube. A 1.5 unit volume of a buffer solution containing 260 mM sodium bicarbonate, 200 mM HEPES and 50 mM sodium hydroxide was mixed with a 10 unit volume of 0.3% aqueous (type II) collagen solution by Koken Co., Ltd., while cooling on ice, and the mixture was placed in the holding tube in which the polylactic acid tube was fixed. A procedure in which the external atmosphere pressure was reduced and restored to ordinary pressure was repeated three times, and then the tube was kept at 37° C. for gelling. After gelling, the 2 mm diameter rod was pulled out and lyophilization was carried out to obtain a collagen cylindrical body.

[0094] The yield elongation of the obtained molded article was measured using a Tensilon device (INSTRON) with reference to DIN53507, 53504, giving a yield elongation value of 38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com