Quantification method of influence of aluminum foil content effect on anti-radiation non-woven material

A technology of non-woven materials and quantitative methods, applied in the field of materials, can solve the problems of unsatisfactory protection effect, stuffy wearing, affecting comfort and work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below with reference to specific embodiments.

[0011] 1. Fiber raw material performance test and experimental plan

[0012] 1.1 Performance test of polyester and viscose fibers

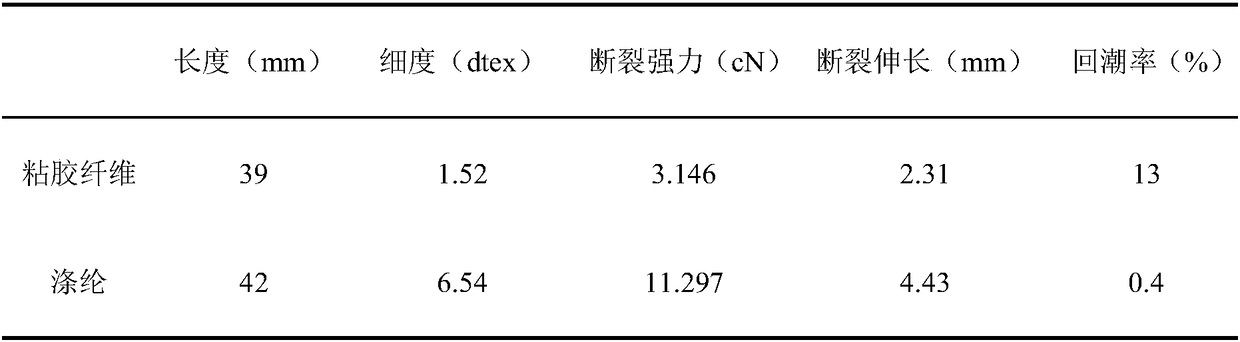

[0013] Before determining the experimental plan, in order to deeply understand the specific properties of the selected fiber raw materials, so as to formulate the experimental plan, the basic physical properties of the fiber raw materials were tested. The test results of various physical properties of the fibers are shown in Table 1.

[0014] The physical properties of table 1 fibers

[0015]

[0016] 1.2 Experimental scheme

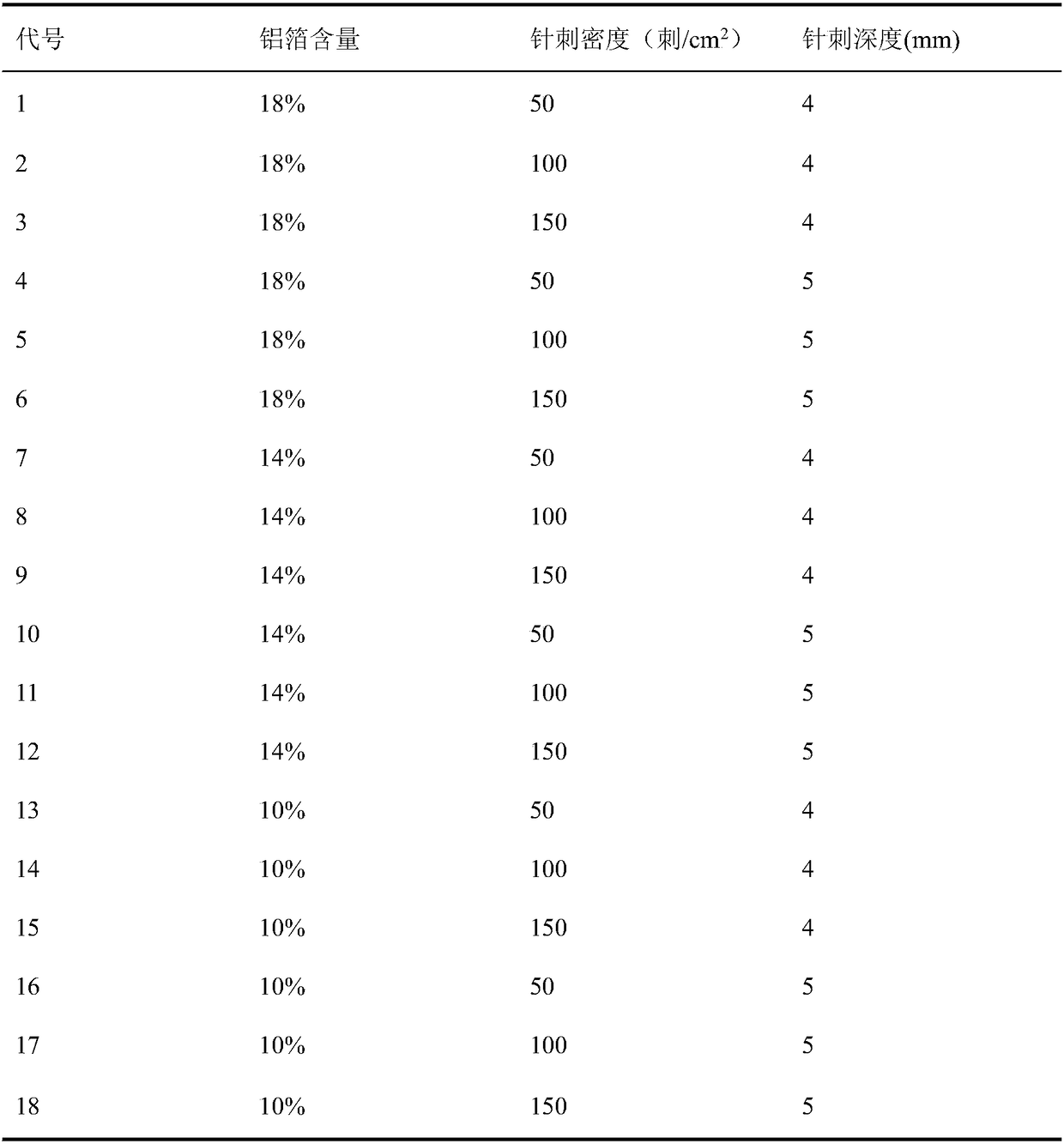

[0017] The electromagnetic shielding performance has a great relationship with the proportion of metal in the material. Therefore, in terms of raw materials, the content of aluminum foil in the final acupuncture material has a great influence on the electromagnetic shielding performance of the anti-electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com