Cationic organosilicon-modified polyurethane emulsion and preparation method thereof

A polyurethane emulsion and cationic technology, which is applied in the field of cationic silicone modified polyurethane emulsion and its preparation, can solve the problems of poor anti-pilling performance, weakened slippage between fibers, loss of textile style, etc. Multi-functional, improved pilling resistance, and the effect of maintaining excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

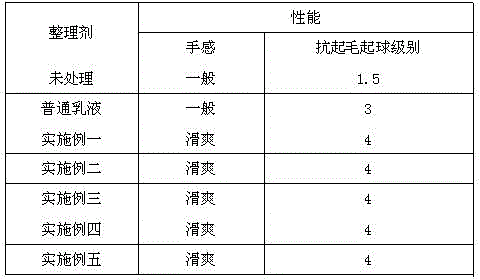

Examples

Embodiment 1

[0028] (1) Synthesis of amino silicone oil: 82.0g of octamethylcyclotetrasiloxane, 17.7g of N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane (Nanjing Xuyang Chemical Co., Ltd. The company's commercially available product, the brand name is coupling agent KH-602), 0.6g end-capping agent hexamethyldisiloxane, 0.7g catalyst potassium hydroxide and 4.1g deionized water are added to the reaction vessel and heated to React at 105°C for 6 hours, and the viscous liquid obtained after cooling is the synthesized amino silicone oil.

[0029] (2) Preparation of quaternized modified amino silicone oil: Add 1.1g bromoethane into the reaction vessel, dissolve in ethanol, heat to 75°C, add 100.0g amino silicone oil dropwise while stirring, and continue the reaction for 5 hours , heated up to 80°C, and reacted for another 1.5 hours, and then vacuumed to remove water and ethanol to obtain quaternized modified amino silicone oil.

[0030](3) Synthesis of cationic silicone-modified polyuretha...

Embodiment 2

[0032] The ethyl bromide in the preparation of the quaternized modified amino silicone oil in Example 1 (2) was replaced with 1.0 g of epichlorohydrin, and the amount of other raw materials and operation steps were the same as in Example 1.

Embodiment 3

[0034] Change the amount of quaternized modified amino silicone oil in Example 1 (3) in the synthesis of cationic silicone-modified polyurethane emulsion to 135.0 g of quaternized modified amino silicone oil, and the amount of other raw materials and operating steps are the same as in Example 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com