Bottle cap automatic cap-arranging device

An automatic and unpacking technology, applied in the direction of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of limited machine promotion, low degree of mechanization, manual unpacking, etc., to achieve simple structure and avoid direct High contact and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

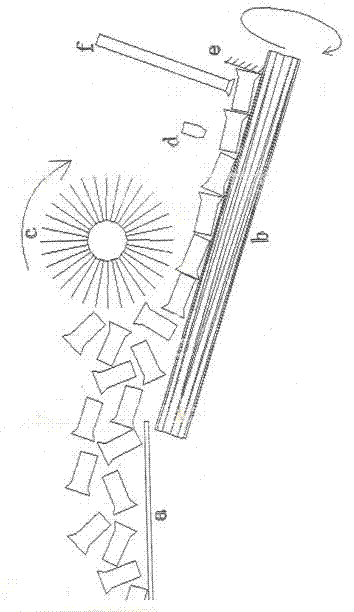

[0017] Accompanying drawing is a kind of specific embodiment of the present invention.

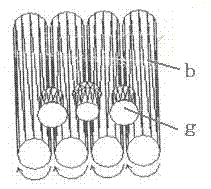

[0018] The automatic cap sorting device for bottle caps of the present invention comprises a material platform a, an array of rotating sorting rods b, an array of counter-rotating plectrums c, a photoelectric detection head d for workpiece attitude, a workpiece baffle e and a turnable grasping manipulator f; the rotating sorting rod Array b includes several rotating rods arranged side by side. The axis direction of the array of rotating finishing rods is low at the front and high at the rear and slopes downward. The anti-rotation plectrum array c is set, and above it is located between the anti-rotation plectrum array and the workpiece baffle, and the workpiece attitude photoelectric detection head d and the steerable grasping manipulator f are arranged in sequence.

[0019] The bottle cap automatic sorting device of the present invention also includes an automatic feeding part, which incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com